In a drop-bottom quench furnace, the quench tank is where the material transformation is locked in. Positioned directly beneath the heating chamber, its purpose is to hold a quenching medium—typically oil, water, or a polymer—that rapidly and uniformly cools the heated components. This extremely fast cooling, enabled by the "drop" mechanism, is the critical step that determines the final hardness, strength, and internal structure of the material.

The quench tank's true role extends beyond simple cooling. Its tight integration with the furnace's drop-bottom design is engineered to minimize the transfer time between heating and cooling, which is essential for achieving the specific metallurgical properties required for high-performance components.

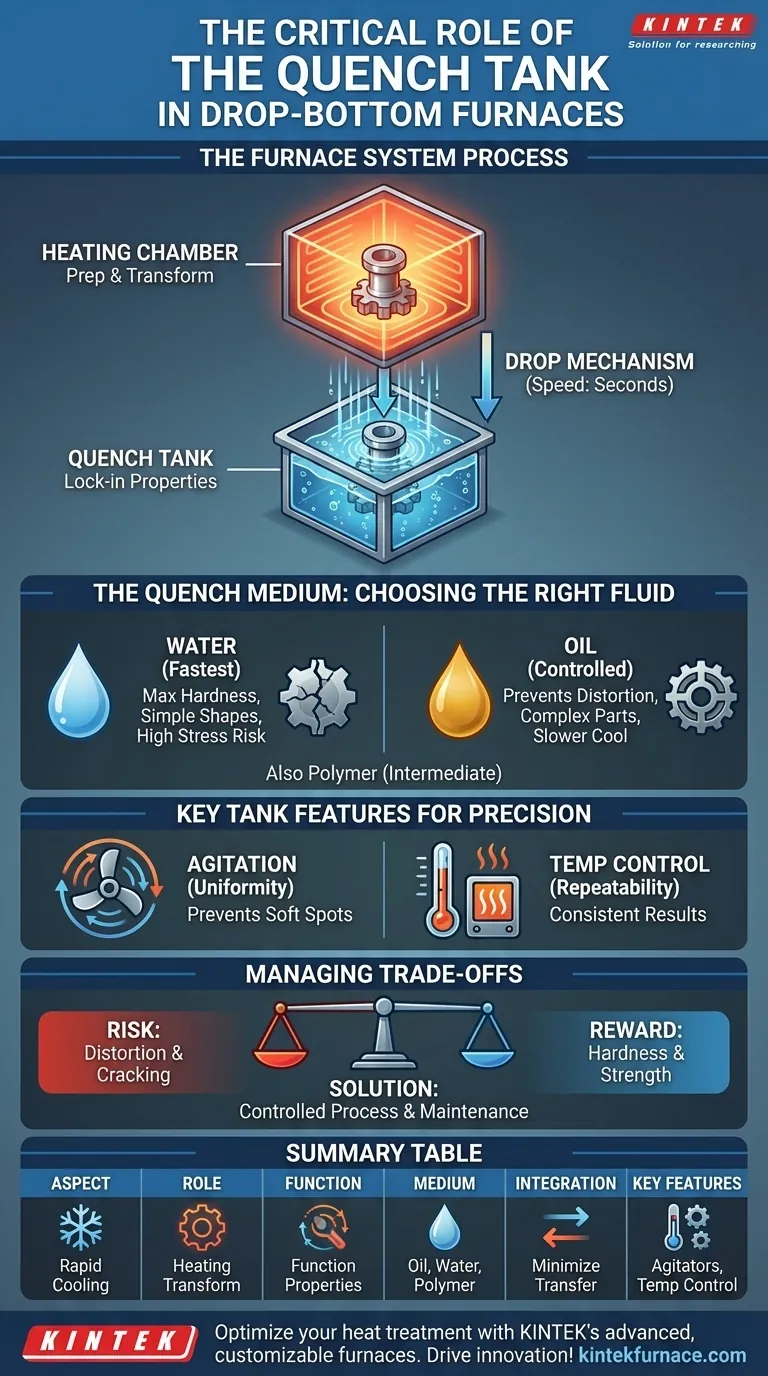

How the Furnace System Achieves its Results

A drop-bottom furnace is not just a collection of parts; it's a highly integrated system designed for speed and precision. The quench tank's function is only understood in the context of the entire process.

The Heating Chamber: Setting the Stage

The process begins in the heating chamber. Here, components are heated to a precise temperature and "soaked" for a specific duration. This phase transforms the material's internal crystalline structure, preparing it for the quench.

The Drop-Bottom Mechanism: The Key to Speed

Once soaking is complete, the bottom of the furnace opens, and the entire load is dropped in a matter of seconds. This rapid transfer is the single most important advantage of this furnace type. It minimizes the time the hot component is exposed to air, preventing unwanted cooling and oxidation that could compromise the final result.

The Quench Tank: Locking in the Properties

The hot load is immediately submerged in the quench tank. The sudden and drastic temperature drop forces the material's internal structure into a new, hardened state (such as martensite in steel). The speed and uniformity of this quench directly dictate the final mechanical properties, such as hardness and tensile strength.

The Critical Role of the Quench Medium

The liquid inside the tank is not an afterthought; it's a carefully selected engineering fluid. The choice of medium and how it is managed are just as important as the furnace temperature.

Water: The Fastest Quench

Water provides the most rapid cooling rate possible. It is highly effective for achieving maximum hardness in simple carbon steels and alloys that are less prone to cracking. However, its severity can introduce high internal stresses.

Oil: A More Controlled Quench

Oil cools parts more slowly than water. This "softer" quench is essential for preventing distortion and cracking in components with complex geometries, sharp corners, or high hardenability. It reduces the risk of thermal shock.

Agitation and Temperature Control

An effective quench tank is not a static pool. It almost always includes agitators (propellers or pumps) to circulate the medium. This ensures that cooling is uniform across all surfaces of the part, preventing soft spots. The temperature of the quench medium itself is also controlled to ensure the process is repeatable batch after batch.

Understanding the Trade-offs

The rapid quench process, while highly effective, comes with inherent risks that must be managed.

Risk of Distortion and Cracking

The primary challenge in quenching is managing thermal stress. The same rapid cooling that creates hardness can also cause parts to warp, distort, or even crack if the process is not perfectly controlled. This is why selecting the right quench medium is so critical.

Medium Degradation and Maintenance

Quench media, especially oil, break down over time. Contamination with water, soot, or scale can dramatically alter the cooling rate and lead to inconsistent results. Regular testing and maintenance of the quench medium are mandatory for any quality-controlled heat treatment operation.

Making the Right Choice for Your Goal

The configuration of your quench process should be tailored to the specific outcome you need for your components.

- If your primary focus is maximum hardness on simple shapes: A rapid, agitated water quench is often the most direct path.

- If your primary focus is preventing distortion in complex parts: A controlled oil quench with managed temperature and agitation is the standard choice to mitigate thermal shock.

- If your primary focus is process repeatability for critical components: You must precisely control the quench medium's temperature, agitation level, and chemical condition.

Ultimately, the quench tank is not a passive container; it is an active and decisive tool for controlling the final performance of your heat-treated components.

Summary Table:

| Aspect | Role of Quench Tank |

|---|---|

| Function | Rapidly cools heated components to lock in material properties like hardness and strength. |

| Medium | Holds quenching fluids (oil, water, polymer) for controlled cooling rates. |

| Integration | Minimizes transfer time with drop-bottom mechanism to prevent oxidation and ensure uniformity. |

| Key Features | Includes agitators and temperature control for repeatable, consistent results. |

Optimize your heat treatment processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our tailored solutions can elevate your material performance and drive innovation in your lab!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis