In the tool and die industry, furnace brazing is a critical process used to join components for molds, dies, and cutting tools. This method serves not only to fabricate these items but also to significantly enhance their hardness and wear resistance, thereby extending their operational lifespan and improving overall manufacturing efficiency. It is also a key strategy for repairing and refurbishing high-value, worn-out tooling.

Furnace brazing is more than a simple joining technique; it's a strategic manufacturing process that creates a complete metallurgical bond. This results in tools and dies that are often stronger, more dimensionally stable, and have a longer service life than those made by other methods.

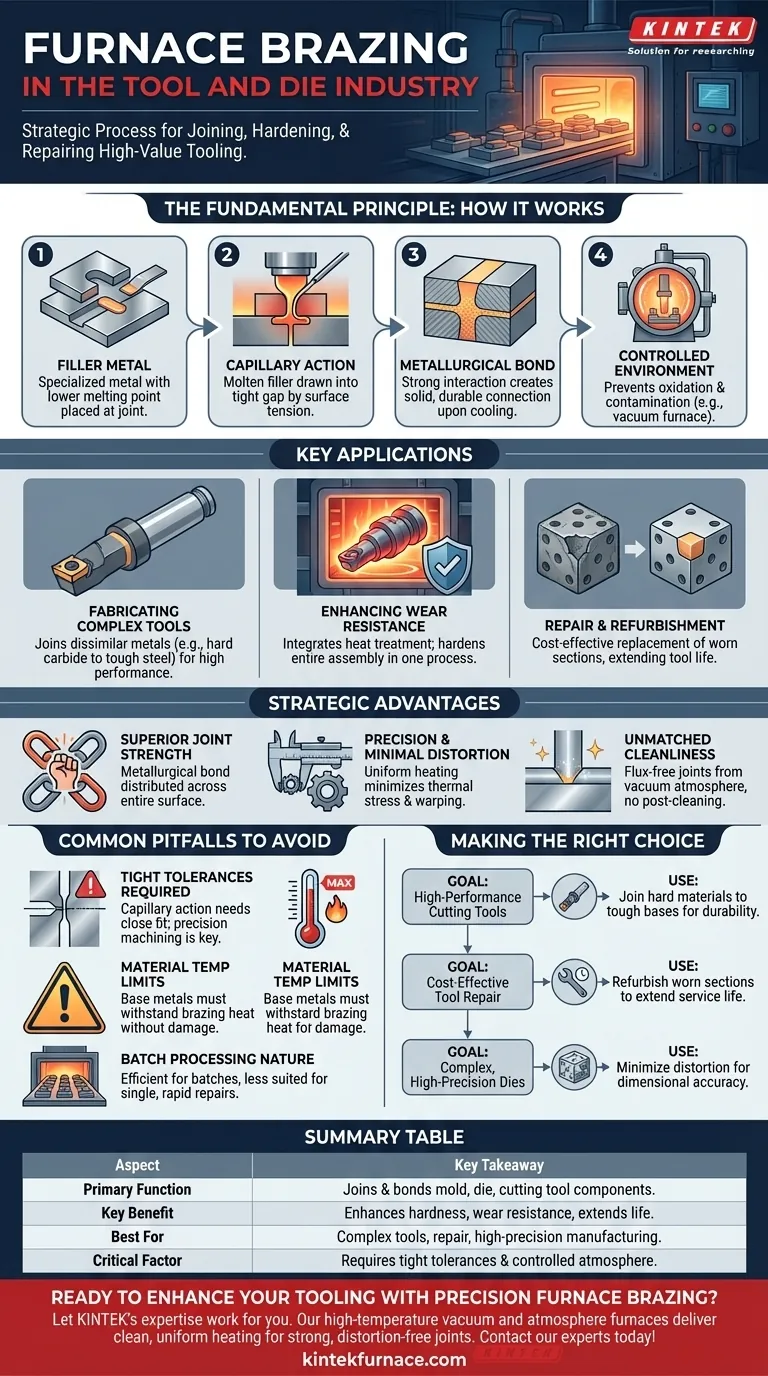

The Fundamental Principle: How Furnace Brazing Works

Furnace brazing is a precise and highly controlled process. It relies on a few core principles to create an exceptionally strong and clean bond between metal components.

The Role of Filler Metal

The process uses a specialized filler metal with a melting point that is lower than the base metals being joined. This filler is placed at the joint before the assembly is heated.

The Power of Capillary Action

Inside the furnace, the entire assembly is heated uniformly. When the temperature reaches the filler metal's melting point, it liquefies and is drawn into the tight gap between the two base parts through a process called capillary action.

Creating a Metallurgical Bond

As the molten filler interacts with the hot surfaces of the base metals, it forms a metallurgical bond. Upon cooling, the filler solidifies, creating a single, solid component where the joint is often as strong as the materials it connects.

The Controlled Environment

This entire process occurs within a controlled atmosphere, such as a vacuum furnace. This prevents oxidation and contamination, ensuring a pure, strong, and reliable bond that is free of impurities.

Key Applications in Tool and Die Manufacturing

The unique characteristics of furnace brazing make it ideal for the demanding requirements of the tool and die industry, where performance and longevity are paramount.

Fabricating Complex Tools

Furnace brazing excels at joining dissimilar metals. This allows manufacturers to bond a very hard material, like tungsten carbide for a cutting edge, to a tougher, more ductile steel shank, creating a single, high-performance tool optimized for its task.

Enhancing Wear Resistance

The high temperatures involved in furnace brazing can be integrated with heat treatment cycles. This allows an entire tool assembly to be joined and hardened in a single, efficient process, locking in superior hardness and wear resistance.

Repair and Refurbishment

Instead of discarding an expensive die with a worn or damaged section, furnace brazing can be used to replace only the failed component. This is a highly cost-effective method for extending the life of valuable tooling assets.

Understanding the Strategic Advantages

Choosing furnace brazing over other joining methods like welding provides several distinct advantages that are critical for high-precision tooling.

Superior Joint Strength

The metallurgical bond created during brazing is distributed across the entire joint surface, resulting in exceptional strength and resistance to vibration and impact.

Precision and Minimal Distortion

Because the entire assembly is heated and cooled uniformly in a furnace, thermal stresses are minimized. This prevents the warping and distortion that can occur with localized heating from welding, which is critical for maintaining the tight tolerances of molds and dies.

Unmatched Cleanliness

The vacuum or controlled atmosphere environment produces exceptionally clean, flux-free joints. This eliminates the need for extensive post-process cleaning and ensures the integrity of the final tool.

Common Pitfalls to Avoid

While powerful, the process is not without its specific requirements and limitations. Understanding these is key to successful implementation.

Requirement for Tight Tolerances

Capillary action depends on a very close fit between the parts being joined. This means that components must be machined with high precision to ensure the filler metal flows correctly and creates a solid bond.

Material Temperature Limits

The base metals themselves must be able to withstand the brazing temperature without being damaged. The material selection for the tool components must account for the heat of the brazing cycle.

Batch Processing Nature

Furnace brazing is a batch process, meaning multiple parts are typically run in a single furnace cycle. This makes it highly efficient for production but less suited for a single, rapid repair compared to a quick welding job.

Making the Right Choice for Your Goal

To apply this process effectively, align your choice with your specific manufacturing or maintenance objective.

- If your primary focus is creating high-performance cutting tools: Use furnace brazing to join hard materials like carbide to tougher base metals for superior wear resistance and durability.

- If your primary focus is cost-effective tool repair: Leverage this process to refurbish expensive dies and molds by replacing only the worn sections, dramatically extending their service life.

- If your primary focus is manufacturing complex, high-precision dies: Choose furnace brazing to minimize thermal distortion and ensure the dimensional accuracy and integrity of intricate geometries.

By understanding furnace brazing as an integrated fabrication and heat treatment process, you can significantly enhance the value and performance of your tooling assets.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Function | Joins and metallurgically bonds components for molds, dies, and cutting tools. |

| Key Benefit | Enhances hardness, wear resistance, and extends tool lifespan. |

| Best For | Fabricating complex tools, cost-effective repair, and high-precision manufacturing. |

| Critical Factor | Requires tight part tolerances and a controlled atmosphere (e.g., vacuum). |

Ready to enhance your tooling with precision furnace brazing?

Our high-temperature vacuum and atmosphere furnaces are engineered to deliver the clean, uniform heating essential for creating strong, distortion-free brazed joints. Whether you are fabricating new, high-performance tools or refurbishing valuable dies, our solutions are designed for reliability and repeatability.

Let KINTEK's expertise work for you. We provide robust and customizable furnace systems to meet the exacting demands of the tool and die industry.

Contact our experts today to discuss how we can support your brazing and heat treatment processes.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement