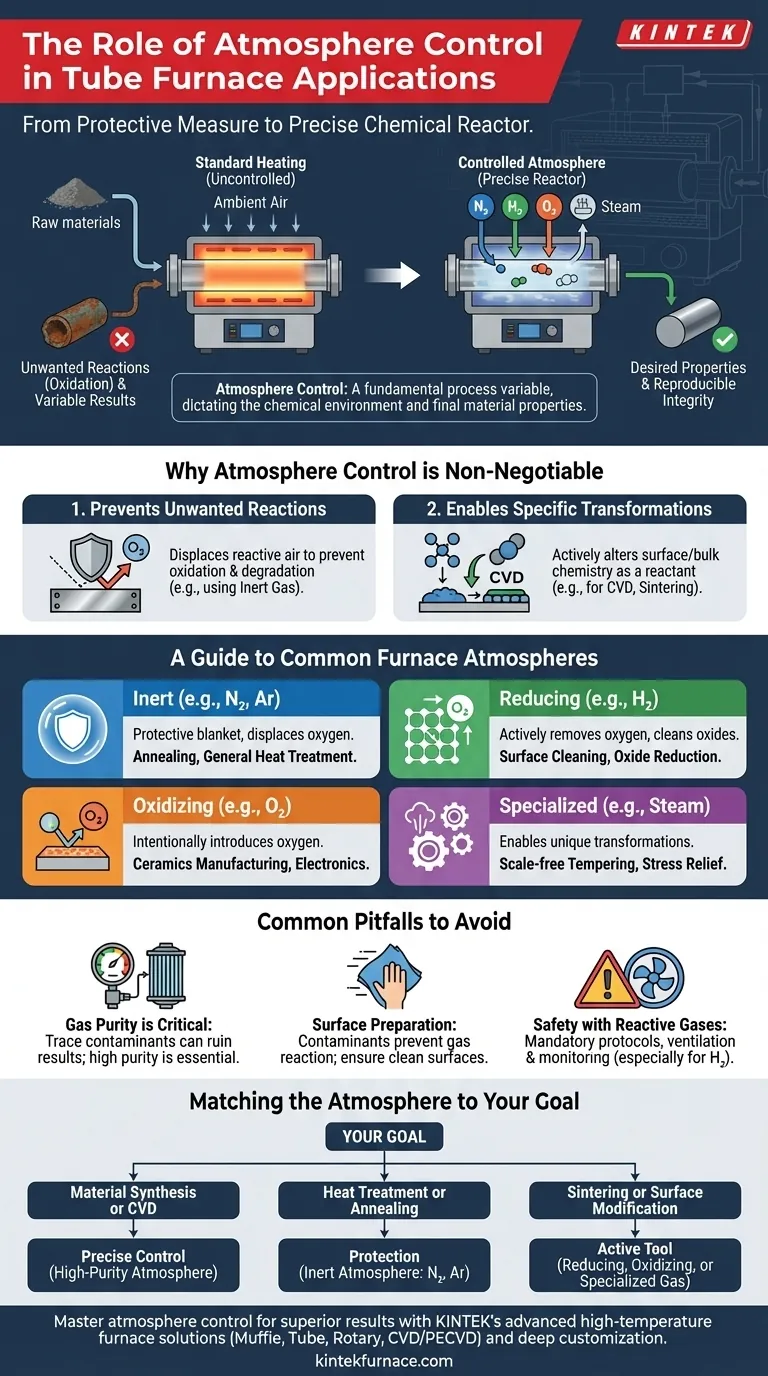

In short, atmosphere control is a fundamental process variable in tube furnace applications, not merely a protective measure. It allows you to dictate the chemical environment during thermal processing, directly influencing the final properties, composition, and integrity of the material you are working with. Without it, you are leaving the outcome of your process to chance.

The core purpose of atmosphere control is to move beyond simply heating a material. It transforms the furnace from a simple oven into a highly precise chemical reactor, enabling you to prevent unwanted reactions or deliberately drive specific chemical transformations at high temperatures.

Why Atmosphere Control is Non-Negotiable

Controlling the atmosphere inside a tube furnace is essential for achieving reproducible and predictable results. It serves two primary functions: preventing undesirable reactions and enabling desired ones.

Preventing Unwanted Reactions

At elevated temperatures, most materials are highly reactive with the ambient air, particularly oxygen. This can lead to unwanted oxidation, forming oxide layers (like rust on iron) that degrade the material's properties.

Using a controlled atmosphere, such as an inert gas, displaces the oxygen and prevents these reactions, preserving the material's purity and surface finish.

Enabling Specific Material Transformations

Atmosphere control is also an active tool. The gas itself can be a reactant in the process, intentionally altering the material's surface or bulk chemistry.

This is critical for applications like Chemical Vapor Deposition (CVD), sintering, and synthesis, where the atmospheric conditions are a key ingredient in creating the final product.

A Guide to Common Furnace Atmospheres

The choice of atmosphere is dictated entirely by the goal of your thermal process. Each type serves a distinct chemical purpose.

Inert Atmospheres (e.g., Nitrogen, Argon)

An inert atmosphere acts as a protective blanket. Its primary role is to create a neutral environment by displacing reactive gases like oxygen.

This is the standard choice for processes like annealing or general heat treatment where the goal is simply to heat the material without altering its chemical composition.

Reducing Atmospheres (e.g., Hydrogen)

A reducing atmosphere is used to actively remove oxygen from a material. It is often used to clean oxides from a surface before a subsequent process or to prevent oxidation in highly sensitive materials.

For this to be effective, surfaces must be clean and free of contaminants before treatment.

Oxidizing Atmospheres (e.g., Oxygen)

Conversely, an oxidizing atmosphere is used to intentionally introduce oxygen into a material's structure or grow a specific oxide layer on its surface.

This is common in the manufacturing of certain ceramics and electronic components where the oxide layer provides essential functional properties.

Specialized Atmospheres (e.g., Steam)

Specific processes may call for unique atmospheres like steam. For iron-based metals, a steam atmosphere can be used for scale-free tempering and stress relief.

This process can increase a material's strength, improve wear and corrosion resistance, and reduce the porosity of sintered parts.

Common Pitfalls to Avoid

While powerful, atmosphere control requires careful planning and an understanding of its limitations and risks.

The Impact of Gas Purity

The purity of your process gas is critical. For highly sensitive applications like semiconductor or advanced materials synthesis, even trace amounts of contaminants in the gas supply can ruin the result. Higher purity gases and leak-tight systems are essential.

The Importance of Surface Preparation

A controlled atmosphere can only react with the surface it can touch. If a material is coated in oils, grease, or an unwanted oxide layer, the process gas will not be able to perform its function correctly, leading to inconsistent results.

Safety Considerations with Reactive Gases

Many process gases, especially hydrogen, are flammable or present other hazards. Implementing proper safety protocols, ventilation, and gas monitoring systems is not optional—it is a mandatory requirement for safe operation.

Matching the Atmosphere to Your Goal

Your choice of atmosphere must be directly linked to your desired outcome. Use this as a guide to make an informed decision.

- If your primary focus is material synthesis or CVD: You need precise control over a high-purity atmosphere to dictate the chemical reactions and final composition of your new material.

- If your primary focus is heat treatment or annealing: Your goal is likely protection, making an inert atmosphere (like nitrogen or argon) the most common and cost-effective choice.

- If your primary focus is sintering or surface modification: You must use the atmosphere as an active tool, choosing a reducing, oxidizing, or specialized gas to achieve the desired density and surface chemistry.

Mastering atmosphere control is the key to unlocking the full potential of your thermal processing.

Summary Table:

| Atmosphere Type | Primary Function | Common Applications |

|---|---|---|

| Inert (e.g., Nitrogen, Argon) | Prevents unwanted reactions by displacing oxygen | Annealing, general heat treatment |

| Reducing (e.g., Hydrogen) | Removes oxygen from materials | Surface cleaning, oxide reduction |

| Oxidizing (e.g., Oxygen) | Introduces oxygen for oxide layer formation | Ceramics manufacturing, electronics |

| Specialized (e.g., Steam) | Enables specific transformations like scale-free tempering | Stress relief, sintering improvements |

Unlock the full potential of your thermal processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Achieve precise atmosphere control and superior results—contact us today to discuss how we can enhance your laboratory's efficiency and innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety