In essence, tubular furnaces serve as high-precision instruments for heat treatment, creating a tightly controlled thermal environment to deliberately alter the properties of materials. They are indispensable for processes where temperature uniformity, atmospheric control, and the prevention of contamination are critical to achieving specific material characteristics in metals, ceramics, and other advanced materials.

The defining role of a tubular furnace is not simply to generate high temperatures, but to provide a sealed, uniform, and controllable environment. This isolation within the tube is what enables advanced material modifications that are difficult to achieve with other furnace types.

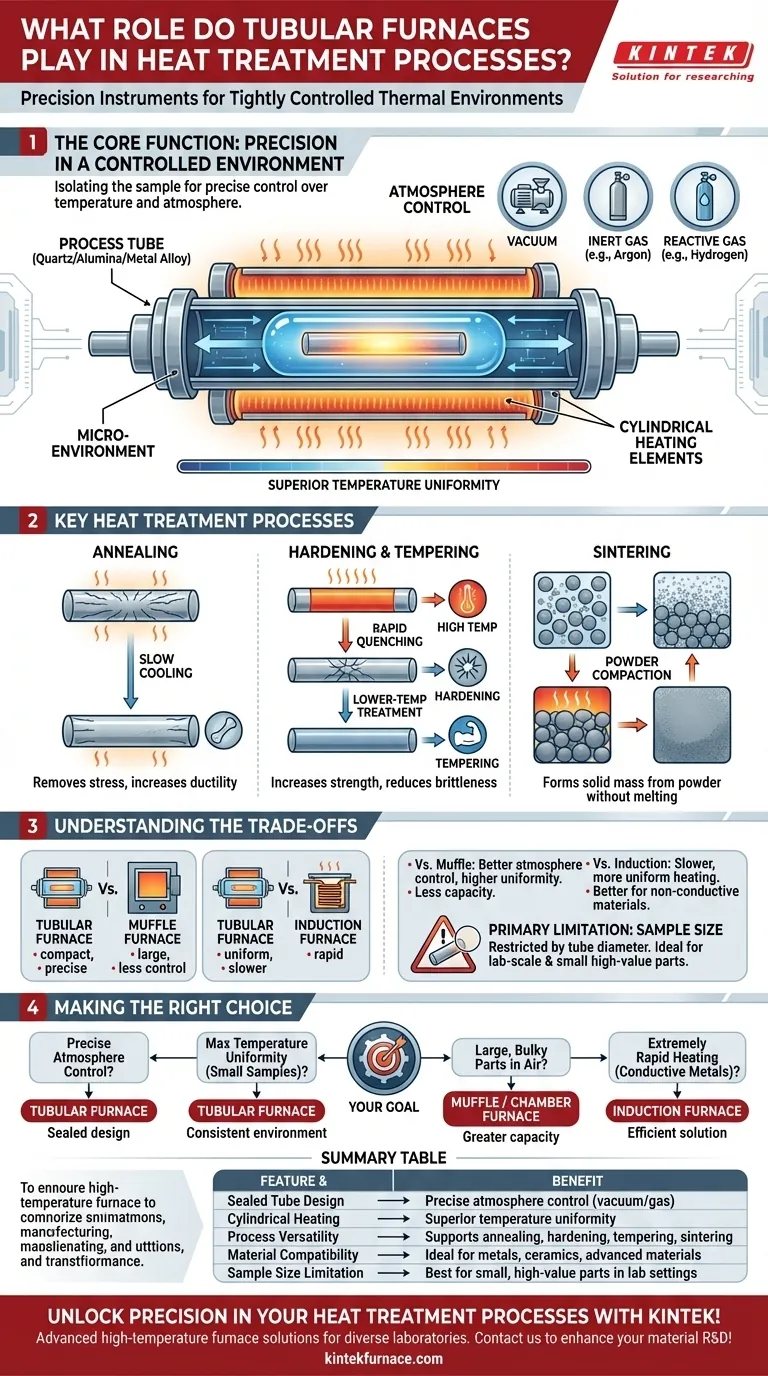

The Core Function: Precision in a Controlled Environment

The unique capabilities of a tubular furnace stem directly from its design, which centers around a process tube. This fundamental difference sets it apart from more general-purpose "box" or "muffle" furnaces.

The Central Role of the Process Tube

The sample is not placed in an open chamber; it is placed inside a tube, typically made of quartz, alumina, or a metal alloy. This tube acts as a micro-environment, isolating the material from the heating elements and the outside atmosphere.

Quartz tubes are especially common due to their high thermal stability, chemical inertness, and low thermal expansion, which prevents cracking during rapid temperature changes.

Achieving Superior Temperature Uniformity

Heating elements are arranged cylindrically around the process tube. This configuration creates a highly uniform temperature zone along the central length of the tube, ensuring the entire sample experiences the same thermal conditions. This uniformity is crucial for consistent and repeatable results.

Enabling Atmosphere Control

The sealed nature of the tube is its most powerful feature. It allows operators to create a specific atmosphere around the sample. This can involve pulling a vacuum to remove reactive gases like oxygen, or introducing specific inert (e.g., Argon) or reactive (e.g., Hydrogen) gases to influence the chemical reactions during heat treatment.

Key Heat Treatment Processes in Tubular Furnaces

This precise control over temperature and atmosphere makes tubular furnaces ideal for a range of sensitive heat treatment applications.

Annealing

This process involves heating a material and then cooling it slowly to remove internal stresses and increase its ductility (ability to deform without fracturing). A tubular furnace allows for very precise control over these slow cooling rates.

Hardening and Tempering

Hardening increases the strength of a metal by heating it to a high temperature and then cooling it rapidly (quenching). Tempering is a subsequent, lower-temperature treatment used to reduce the brittleness that hardening can cause. The precise temperature control of a tubular furnace is key to hitting the exact targets for both processes.

Sintering

Sintering is the process of compacting and forming a solid mass of material from a powder using heat, without melting it to the point of liquefaction. Tubular furnaces are widely used for sintering ceramics and metal powders, especially when a controlled atmosphere is required to prevent oxidation.

Understanding the Trade-offs: Tubular vs. Other Furnaces

While powerful, a tubular furnace is not always the right tool. Understanding its relationship to other furnace types is key to making an informed decision.

Tubular vs. Muffle Furnaces

Muffle (or chamber) furnaces are general-purpose "hot boxes" suitable for heating materials in air. While they can handle larger or more awkwardly shaped parts, they offer very limited atmosphere control and less precise temperature uniformity compared to a tubular furnace.

Tubular vs. Induction Furnaces

Induction furnaces heat conductive materials directly and very rapidly using an electromagnetic field. They are extremely efficient for processes like rapid quenching. However, tubular furnaces are superior for applications requiring slower, highly uniform heating of the entire sample or for processing non-conductive materials like ceramics.

Primary Limitation: Sample Size

The most significant trade-off of a tubular furnace is its limited sample volume. The diameter of the process tube inherently restricts the size of the components that can be treated, making them more suitable for laboratory-scale work, research, or the processing of small, high-value parts.

Making the Right Choice for Your Goal

Selecting the correct furnace depends entirely on the specific requirements of your heat treatment process.

- If your primary focus is precise atmosphere control (vacuum or specific gas): A tubular furnace is the essential choice due to its sealed tube design.

- If your primary focus is maximum temperature uniformity for small samples: A tubular furnace provides the most consistent and repeatable thermal environment.

- If your primary focus is processing large, bulky, or numerous parts in air: A muffle or chamber furnace offers greater capacity and practicality.

- If your primary focus is extremely rapid heating of conductive metals: An induction furnace is the most efficient solution.

Understanding these core principles ensures you select not just a furnace, but the precise tool for achieving your desired material properties.

Summary Table:

| Feature | Benefit |

|---|---|

| Sealed Tube Design | Enables precise atmosphere control (vacuum or gas) |

| Cylindrical Heating | Provides superior temperature uniformity |

| Process Versatility | Supports annealing, hardening, tempering, and sintering |

| Material Compatibility | Ideal for metals, ceramics, and advanced materials |

| Sample Size Limitation | Best for small, high-value parts in lab settings |

Unlock precision in your heat treatment processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our tubular furnaces can enhance your material research and development!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents