In tool manufacturing, heat treatment furnaces are not an optional step; they are the critical process that transforms a shaped piece of metal into a high-performance instrument. These furnaces precisely control temperature to temper or anneal materials, creating the specific hardness, toughness, and wear resistance required for demanding applications like cutting, molding, and stamping. Without this controlled thermal process, a tool would be too soft to hold an edge or too brittle to withstand operational stress.

A heat treatment furnace fundamentally alters the internal crystalline structure of tool steel. This controlled transformation is the only way to balance the conflicting properties of hardness (for a sharp, lasting edge) and toughness (to resist chipping and breaking under stress).

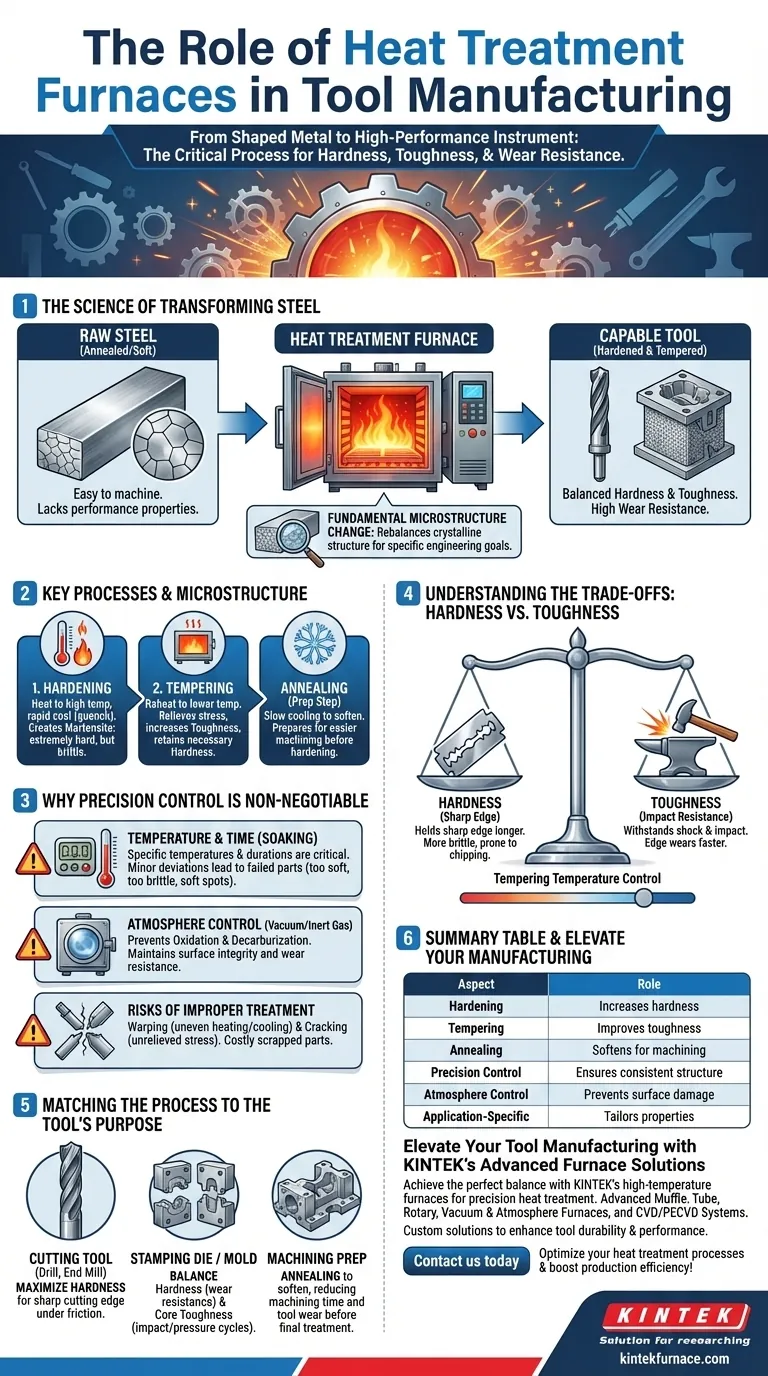

The Science of Transforming Steel

A tool's final performance is determined not by its shape alone, but by its internal microstructure. Heat treatment is the science of manipulating this structure to achieve a specific engineering goal.

From Raw Steel to a Capable Tool

Raw tool steel is often delivered in an annealed, or softened, state. This makes it easier and more cost-effective to machine, cut, and shape into its final form. However, in this soft state, it lacks the properties needed to function as a tool.

The Role of Microstructure

The properties of steel—its hardness, toughness, and wear resistance—are dictated by its internal crystal structure, known as its microstructure. The goal of heat treatment is to rearrange this microstructure in a precise and predictable way.

Key Processes: Hardening and Tempering

The most common two-step process involves hardening and tempering. First, the tool is heated to a very high, specific temperature and then rapidly cooled (quenched). This "freezes" the steel in an extremely hard but also very brittle state called martensite.

Next, the tool is tempered by reheating it to a lower temperature. This crucial step relieves internal stresses and reduces brittleness, increasing the tool's toughness while retaining the necessary hardness.

Annealing: Preparing for Machining

Annealing is a separate process used to achieve the opposite effect. By heating the steel and then cooling it very slowly, the material becomes soft and ductile. This is often done before machining to make the shaping process easier, after which the finished part will undergo hardening and tempering.

Why Precision Control is Non-Negotiable

The success of heat treatment hinges on the furnace's ability to execute a thermal recipe with absolute precision. Minor deviations can lead to a completely failed part.

The Impact of Temperature

The target temperatures for hardening and tempering are extremely specific to the steel alloy being used. A deviation of even a few degrees can result in a tool that is too soft, too brittle, or has internal soft spots, rendering it useless.

The Importance of Time (Soaking)

The tool must be held at the target temperature for a specific duration, a process known as soaking. This ensures the heat penetrates the entire volume of the tool uniformly and that the desired microstructural change is complete.

The Atmosphere Inside the Furnace

For high-performance tools, the atmosphere within the furnace is also critical. Using a vacuum or inert gas atmosphere prevents oxidation and surface decarburization—a loss of carbon from the steel's surface—which would degrade the tool's performance and wear resistance.

Understanding the Trade-offs

Heat treatment is not about maximizing a single property; it's about achieving the optimal balance for a specific application. Understanding these compromises is key to understanding tool design.

Hardness vs. Toughness

This is the central trade-off in tool manufacturing. A harder tool holds a sharp edge longer but is more brittle and prone to chipping under shock. A tougher tool can withstand impact but its edge may wear down faster. The tempering temperature directly controls this balance.

The Risk of Improper Treatment

A poorly executed heat treatment cycle is costly. The most common failures are warping due to uneven heating or cooling, and cracking from unrelieved internal stresses. This can scrap a part that has already undergone expensive and time-consuming machining.

Cost and Throughput

Heat treatment is an energy-intensive and often lengthy process. Furnaces represent a significant capital investment and their operational cycle time can be a bottleneck in the overall production workflow. However, this cost is essential to create a tool that performs reliably.

Matching the Process to the Tool's Purpose

The correct heat treatment protocol is determined entirely by the tool's intended function.

- If your primary focus is a cutting tool (e.g., a drill bit or end mill): The heat treatment must maximize hardness to maintain a sharp cutting edge under friction and high temperatures, even at the cost of some toughness.

- If your primary focus is a stamping die or mold: The treatment must balance high surface hardness for wear resistance with significant core toughness to withstand millions of cycles of impact and pressure without cracking.

- If your primary focus is preparing steel for complex machining: The key process is annealing, which softens the material to reduce machining time, tool wear, and the overall cost of fabrication before the final hardening cycle.

Ultimately, mastering the heat treatment process is what separates a simple metal object from a durable, high-precision industrial tool.

Summary Table:

| Aspect | Role in Tool Manufacturing |

|---|---|

| Hardening | Increases hardness by heating and rapid cooling to form martensite. |

| Tempering | Reduces brittleness, improves toughness after hardening. |

| Annealing | Softens steel for easier machining before final treatment. |

| Precision Control | Ensures exact temperature and time for consistent microstructure. |

| Atmosphere Control | Prevents oxidation and decarburization in vacuum or inert gas environments. |

| Application-Specific | Tailors hardness vs. toughness balance for cutting, molding, or stamping tools. |

Elevate Your Tool Manufacturing with KINTEK's Advanced Furnace Solutions

Struggling to achieve the perfect balance of hardness and toughness in your tools? KINTEK specializes in high-temperature furnaces designed for precision heat treatment. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements, enhancing tool durability and performance.

Contact us today to discuss how our tailored furnace systems can optimize your heat treatment processes and boost your production efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production