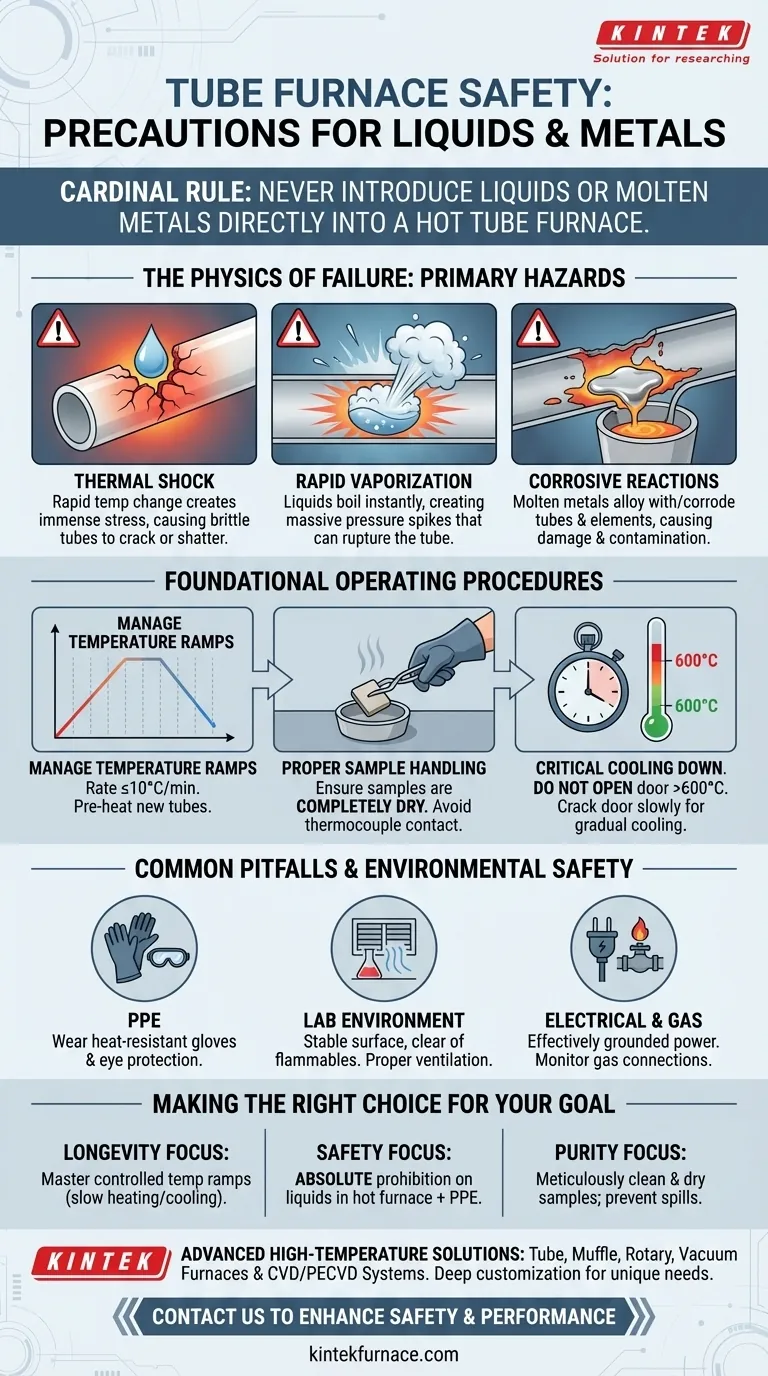

Above all, never introduce liquids or molten metals directly into a hot tube furnace. This is the cardinal rule of operation. Doing so risks violent, rapid vaporization and catastrophic thermal shock, which can destroy the furnace tube, damage heating elements, and create a significant safety hazard. All other precautions are secondary to this fundamental principle.

The core challenge in operating a tube furnace is managing extreme temperature gradients. The central precautions regarding liquids and metals are designed to prevent two primary failure modes: catastrophic cracking from thermal shock and destructive chemical reactions or contamination at high temperatures.

The Physics of High-Temperature Failure

Operating a tube furnace safely requires an understanding of the immense stresses placed on its materials. The prohibitions are not arbitrary; they are based on fundamental physics that can lead to equipment failure and operator injury.

The Primary Danger: Thermal Shock

Thermal shock occurs when a rapid change in temperature creates stress within a material. This is especially dangerous in the ceramic (alumina or quartz) tubes used in these furnaces.

When a cooler liquid or metal touches the hot inner surface of the furnace tube, that small area contracts instantly while the surrounding material remains expanded. This differential creates immense internal stress, often causing the brittle ceramic to crack or shatter.

Think of pouring cold water into a hot glass baking dish—the same principle applies, but at far more extreme temperatures.

The Hazard of Rapid Vaporization

Injecting a liquid into a tube furnace heated to hundreds or thousands of degrees causes near-instantaneous boiling.

A small amount of liquid, like water, expands over 1,500 times its original volume when it turns to steam. This creates a sudden, massive pressure spike inside the tube, which can rupture it violently, expelling hot fragments and hazardous materials.

The Corrosive Nature of Molten Metals

Spilling molten metals inside a furnace presents a dual threat. First, like any liquid, they can cause thermal shock.

Second, many molten metals are highly reactive. They can alloy with, corrode, and permanently damage the process tube, the crucibles, or even the furnace's heating elements, leading to costly repairs and contamination of future experiments.

Foundational Operating Procedures

Beyond the specific handling of liquids and metals, a baseline of disciplined procedure is essential for safety and equipment longevity. These practices protect both the operator and the instrument.

Managing Temperature Ramps

The integrity of the furnace tube depends on slow, controlled temperature changes. Both heating and cooling must be gradual to prevent thermal shock.

As a rule, heating and cooling rates should not exceed 10°C per minute. For new tubes, an initial pre-heating cycle is critical to bake out contaminants and relieve manufacturing stresses.

Proper Sample Handling

All samples must be properly prepared before being placed in the furnace. This includes ensuring they are completely dry to prevent any unintended vaporization.

When loading and unloading, use crucible tongs gently. Never allow samples or tongs to touch the thermocouple, as the delicate sensor can easily break at high temperatures, compromising temperature control.

The Critical Cooling Down Process

Resist the urge to open the furnace immediately after a run. Opening the door while the interior is extremely hot will cause a rush of cool air, creating the same thermal shock you work to avoid during heating.

Do not open the furnace door if the temperature is above 600°C. Once below this threshold, crack the door open just a small amount to allow for slow, gradual cooling before fully opening it to remove your samples.

Common Pitfalls and Environmental Hazards

Simple mistakes or a poor lab environment can undermine even the most careful furnace operation.

Personal Protective Equipment (PPE)

The high temperatures demand respect. Always wear heat-resistant gloves and appropriate eye protection when working near the furnace, especially during loading and unloading procedures.

Lab Environment and Placement

The furnace must be placed on a stable surface, away from any severe vibrations. Keep the surrounding area clear of all flammable, explosive, or wet materials.

Proper ventilation is non-negotiable to safely dissipate heat and any potential off-gassing from your samples.

Electrical and Gas Safety

Ensure the furnace is connected to an effectively grounded power source to prevent any risk of electric shock. If you are using process gases, regularly monitor all connections and flow rates to prevent dangerous leaks.

Making the Right Choice for Your Goal

Your specific priorities will dictate which precautions to emphasize, but all are interconnected components of a safe and effective process.

- If your primary focus is equipment longevity: Master controlled temperature ramps. Slow heating and even slower, staged cooling are the most critical factors in extending the life of your furnace tube.

- If your primary focus is operator safety: The absolute prohibition on introducing liquids into a hot furnace is your most important rule. This, combined with consistent use of PPE, prevents the most common and dangerous accidents.

- If your primary focus is experimental purity: Meticulously clean and dry your samples before every run. Careful handling to prevent spills inside the furnace will ensure your results are not compromised by cross-contamination.

Ultimately, successful and safe tube furnace operation is an exercise in deliberate control and a deep respect for the materials involved.

Summary Table:

| Precaution | Key Reason | Impact |

|---|---|---|

| Never introduce liquids or molten metals into a hot furnace | Prevents rapid vaporization and thermal shock | Avoids tube cracking, equipment damage, and safety hazards |

| Use controlled temperature ramps (≤10°C/min) | Reduces thermal stress on materials | Extends furnace life and maintains integrity |

| Ensure samples are completely dry | Eliminates unintended vaporization | Prevents pressure spikes and contamination |

| Wear heat-resistant gloves and eye protection | Protects against high-temperature exposure | Enhances operator safety during handling |

| Maintain proper ventilation and clear lab area | Dissipates heat and prevents hazards | Reduces risks of accidents and off-gassing |

Ensure your laboratory operates safely and efficiently with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, helping you prevent hazards and achieve consistent results. Contact us today to discuss how our tailored solutions can enhance your safety and performance!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents