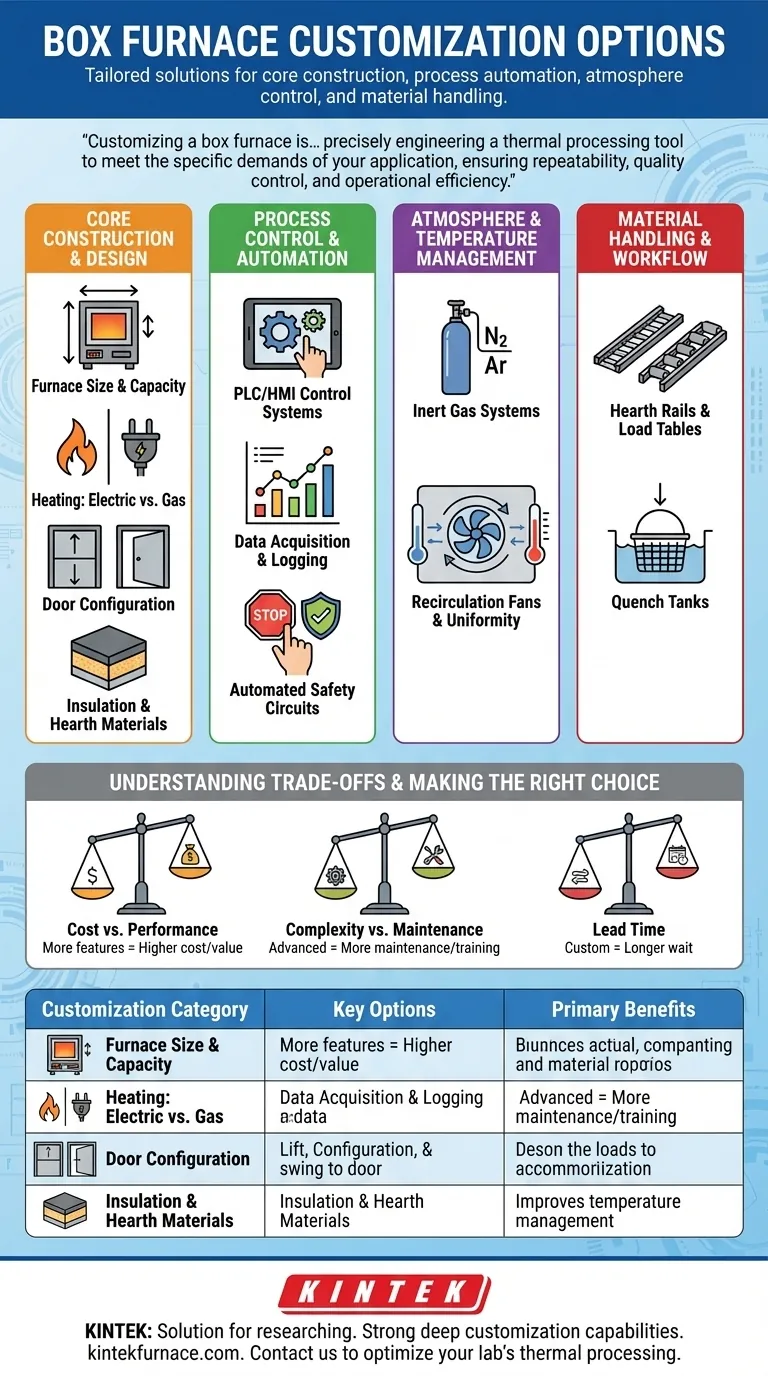

In short, box furnace customization options span from core construction choices to advanced systems for process automation, atmosphere control, and material handling. The key options include programmable logic controllers (PLC) with human-machine interfaces (HMI), data acquisition systems, inert gas capabilities, recirculation fans for temperature uniformity, and integrated material handling like hearth rails and quench tanks.

Customizing a box furnace is not about adding features for their own sake. It is about precisely engineering a thermal processing tool to meet the specific demands of your application, ensuring repeatability, quality control, and operational efficiency.

Core Construction and Design Choices

Before considering add-ons, the fundamental design of the furnace must match your operational needs. These initial decisions have the most significant impact on cost and capability.

Furnace Size and Capacity

The internal chamber dimensions and load capacity are the most basic specifications. This must be determined by the size and volume of the parts you intend to process in a typical batch.

Heating Method: Electric vs. Gas

Furnaces can be heated by electricity or natural gas. Electric heat, controlled by a Silicon Controlled Rectifier (SCR), is standard and provides clean, precise temperature control. Gas heat may offer operational cost savings in some regions but introduces different combustion by-products.

Door Configuration

The furnace door design impacts loading access and heat retention. A vertical lift door is ideal for conserving floor space, while a traditional swing-out door is simpler mechanically.

Insulation and Hearth Materials

Modern furnaces use high-density, energy-efficient insulation to minimize heat loss. The hearth, which supports the workload, is typically made of heavy-duty cast materials, but its composition can be customized for specific load weights or chemical compatibility.

Process Control and Automation

These systems define how you interact with the furnace and how precisely it executes a thermal cycle. They are critical for ensuring process repeatability and traceability.

Control Systems: PLC/HMI

While a standard furnace may use a simple electronic timer, upgrading to a PLC/HMI provides full process automation. This allows you to program, store, and execute complex multi-step recipes for temperature ramps, soaks, and controlled cooling.

Data Acquisition and Logging

For quality control and certification, a data acquisition system is essential. It automatically records temperature, time, and other process variables, creating a permanent record for each batch that can be exported for analysis.

Automated Safety and Shutdown Circuits

Beyond a standard E-stop, you can specify automatic shutdown circuits. These can be programmed to safely shut down the furnace if it deviates from setpoint tolerances or if other ancillary equipment fails, protecting both the product and the equipment.

Atmosphere and Temperature Management

These options control the environment inside the furnace, which is critical for processing sensitive materials.

Inert Gas Systems

For applications like annealing or brazing where oxidation must be prevented, an inert gas system is required. This system purges oxygen from the chamber and maintains a positive pressure environment using gases like nitrogen or argon.

Recirculation Fans and Uniformity

Standard furnaces rely on radiant heat, which can lead to temperature variations. A recirculation fan forces convection, dramatically improving temperature uniformity throughout the chamber. This is often specified as a tolerance, such as +/- 10°F, and is crucial for consistent results across large parts or dense loads.

Material Handling and Workflow Integration

These features are designed to streamline the loading and unloading process, improving safety and throughput.

Hearth Rails, Load Tables, and Quench Tanks

For heavy workloads, hearth roller rails can be built into the furnace floor. These align with external load tables or charge cars, simplifying the transfer of material. A quench tank, often integrated with the load/unload station, allows for rapid cooling of parts as a part of the heat-treating process.

Understanding the Trade-offs

Choosing customization options involves balancing performance against complexity and cost.

Cost vs. Performance

Every option, from a PLC to an inert gas system, adds to the initial capital cost. You must weigh the price of the feature against the tangible value it provides, such as reduced scrap rates, improved consistency, or lower labor costs.

Complexity vs. Maintenance

Advanced systems require more sophisticated maintenance and operator training. A fully automated furnace with an inert gas manifold is a more complex piece of machinery than a basic box furnace with a manual timer.

Lead Time

Standard, pre-engineered furnaces have the shortest lead times. Extensive customization requires additional engineering and fabrication time, which must be factored into your project schedule.

Making the Right Choice for Your Application

To select the right options, focus on the primary goal of your thermal process.

- If your primary focus is high-volume production and repeatability: Prioritize a PLC/HMI for automation and material handling options like roller hearths to reduce cycle time.

- If your primary focus is processing sensitive or high-value materials: Invest in an inert gas system to control oxidation and recirculation fans to ensure strict temperature uniformity.

- If your primary focus is general-purpose heating with a limited budget: A standard furnace configuration with basic digital controls is often sufficient and provides the best value.

Ultimately, the right customizations transform a generic furnace into a purpose-built solution for your specific thermal processing challenge.

Summary Table:

| Customization Category | Key Options | Primary Benefits |

|---|---|---|

| Process Control & Automation | PLC/HMI, Data Acquisition | Enhanced repeatability, traceability, automation |

| Atmosphere & Temperature | Inert Gas Systems, Recirculation Fans | Oxidation control, improved temperature uniformity |

| Material Handling | Hearth Rails, Quench Tanks | Streamlined workflow, increased safety and throughput |

| Core Construction | Size, Heating Method, Door Type | Matches operational needs, cost-effectiveness |

Ready to optimize your lab's thermal processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization capabilities. Whether you're in high-volume production, handling sensitive materials, or need general-purpose heating, we'll engineer a box furnace that ensures repeatability, quality control, and operational efficiency. Contact us today to discuss your requirements and discover how our custom solutions can elevate your experiments!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control