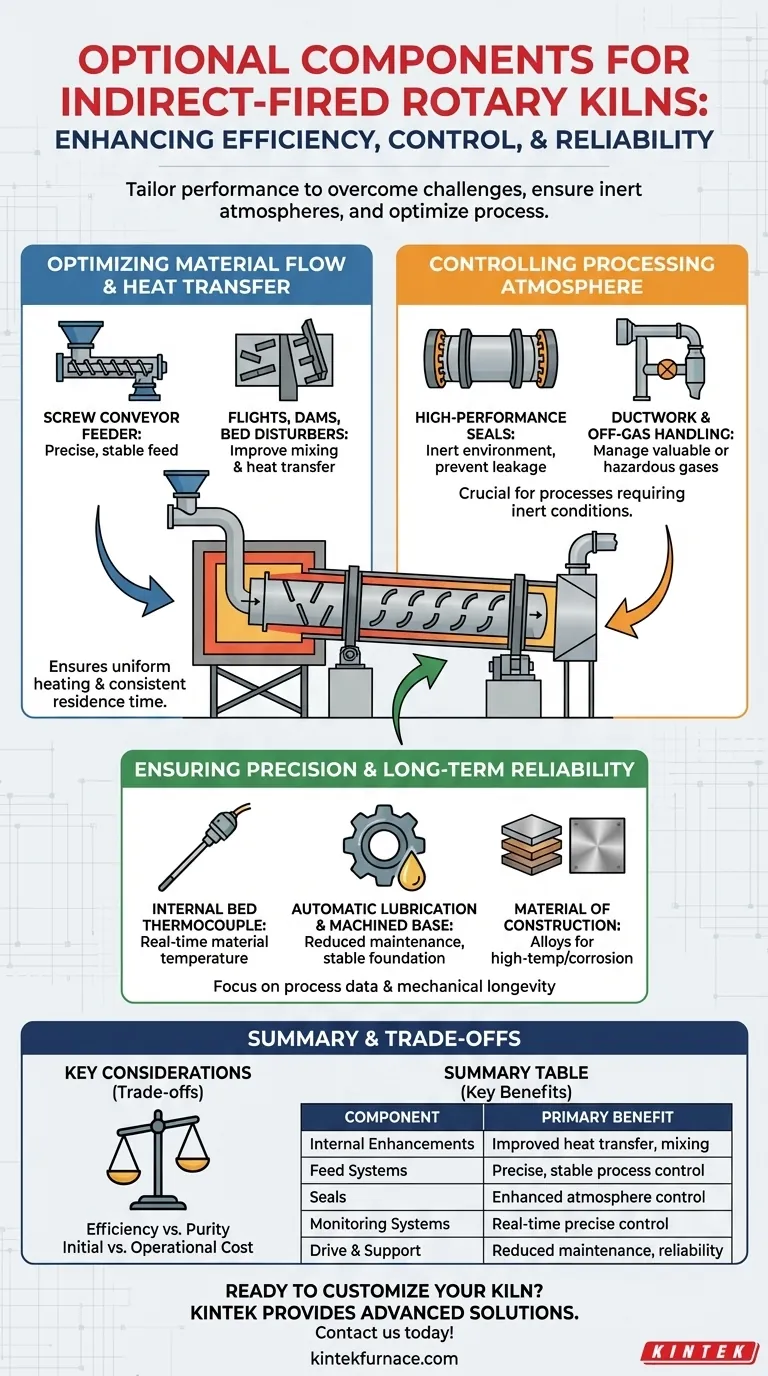

At its core, an indirect-fired rotary kiln can be enhanced with several optional components designed to improve efficiency, control the processing atmosphere, and ensure operational reliability. Key options include specialized inlet and discharge seals, internal enhancements like flights and dams, precision feeders such as screw conveyors, and systems for process monitoring and automated maintenance.

The selection of optional components is not about adding features, but about strategically overcoming the inherent challenges of indirect heating. Each option serves to tailor the kiln's performance to a specific material and a precise processing goal, turning a general piece of equipment into a specialized solution.

The Purpose of Optional Components

Indirect-fired kilns heat material by rotating it inside a cylinder that is externally heated within a furnace. This design is perfect for processes requiring a controlled or inert atmosphere, as the material never contacts combustion gases.

However, this method introduces challenges in heat transfer and process control. Optional components are engineered solutions to mitigate these challenges and optimize the kiln's performance.

Optimizing Material Flow and Heat Transfer

The primary goal inside the kiln is to ensure every particle is heated uniformly. Several components exist to achieve this.

Internal Enhancements

Flights are metal lifters welded to the kiln's interior shell. As the kiln rotates, these flights lift the material and cascade it through the heated atmosphere inside the drum, dramatically improving heat transfer efficiency and mixing.

Dams are rings installed inside the kiln to increase the material's residence time and bed depth in a specific zone, allowing for more thorough processing.

Bed disturbers are an aggressive form of internal agitation used to break up clumps and ensure even exposure in materials prone to agglomeration.

The Feed System

A screw conveyor feeder is often recommended to introduce material into the kiln at a precise, consistent rate. This prevents surges and ensures a stable process, which is critical for achieving a uniform end product.

Controlling the Processing Atmosphere

The single greatest advantage of an indirect kiln is atmosphere control. Seals are the most critical component for realizing this benefit.

Inlet and Discharge Seals

Standard seals provide a basic barrier, but optional high-performance seals are essential for applications requiring a near-perfectly inert environment. These advanced seals minimize air ingress and prevent the escape of valuable process gases or fine powders.

Ductwork and Off-Gas Handling

Custom ductwork is designed to safely and efficiently manage the gases exiting the process. This is vital for applications like pyrolysis, where off-gases may be valuable, or for processes where they must be routed to scrubbers or other treatment systems.

Ensuring Precision and Long-Term Reliability

These components focus on process data and the mechanical longevity of the kiln.

Internal Bed Temperature Measurement

While the furnace temperature is easily measured, the actual temperature of the material bed can differ. An optional internal thermocouple provides real-time data from inside the material bed, enabling exceptionally precise temperature control.

Drive and Support Systems

An automatic gear lubrication system ensures the main drive gear and pinion are consistently lubricated, reducing wear and minimizing manual maintenance. A machined base provides a perfectly flat and level foundation, which is crucial for preventing kiln shell distortion and ensuring the long-term integrity of the drive train and support rollers.

Material of Construction

The choice of material for the kiln shell is a critical decision. Options range from carbon steel for low-temperature applications to stainless steel and specialty alloys (like Inconel) for high-temperature or corrosive environments. This choice directly impacts the kiln's operational limits and lifespan.

Understanding the Trade-offs

Choosing components for an indirect kiln involves balancing performance with cost and complexity.

Efficiency vs. Purity

The fundamental trade-off of an indirect kiln is lower heat transfer efficiency in exchange for absolute process purity. Internals like flights help close this efficiency gap but add to the initial cost and complexity.

Initial Cost vs. Operational Cost

Components like an automatic lubrication system or a machined base increase the upfront investment. However, they pay for themselves over the kiln's life through reduced maintenance, less downtime, and greater operational stability. Neglecting them can lead to higher long-term costs.

Making the Right Choice for Your Process

Your choice of components should be driven entirely by your end goal.

- If your primary focus is process purity and atmosphere control: Invest in the highest-quality inlet and discharge seals and select a shell alloy resistant to your specific process chemistry.

- If your primary focus is maximizing throughput: Prioritize internal enhancements like flights and an internal temperature measurement system to optimize heat transfer and residence time.

- If your primary focus is reliability and low maintenance: Specify an automatic lubrication system and a machined base to ensure the mechanical integrity of the kiln for years to come.

Ultimately, a well-specified kiln is a purpose-built instrument, with each component selected to guarantee your desired outcome.

Summary Table:

| Component Type | Key Examples | Primary Benefits |

|---|---|---|

| Internal Enhancements | Flights, Dams, Bed Disturbers | Improved heat transfer, uniform heating, better mixing |

| Feed Systems | Screw Conveyor Feeder | Precise material feed, stable process control |

| Seals | High-Performance Inlet/Discharge Seals | Enhanced atmosphere control, reduced gas leakage |

| Monitoring Systems | Internal Thermocouple | Real-time bed temperature data, precise control |

| Drive and Support | Automatic Lubrication, Machined Base | Reduced maintenance, long-term reliability |

| Material Options | Stainless Steel, Specialty Alloys | Corrosion resistance, high-temperature durability |

Ready to customize your indirect-fired rotary kiln for superior performance? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency, control, and reliability. Contact us today to discuss how we can tailor a solution for your specific process needs!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What types of physical and chemical transformations occur in a rotary kiln? Master Material Processing for Superior Results

- What are the primary applications of an electric rotary kiln? Achieve High-Purity Material Processing with Precision

- What distinguishes direct from indirect rotary kilns? Choose the Right Kiln for Your Material

- What supporting equipment is needed for a rotary kiln system? Essential Components for Efficient Thermal Processing

- What are some common processes carried out in rotary kilns? Unlock Efficient Material Transformation Solutions