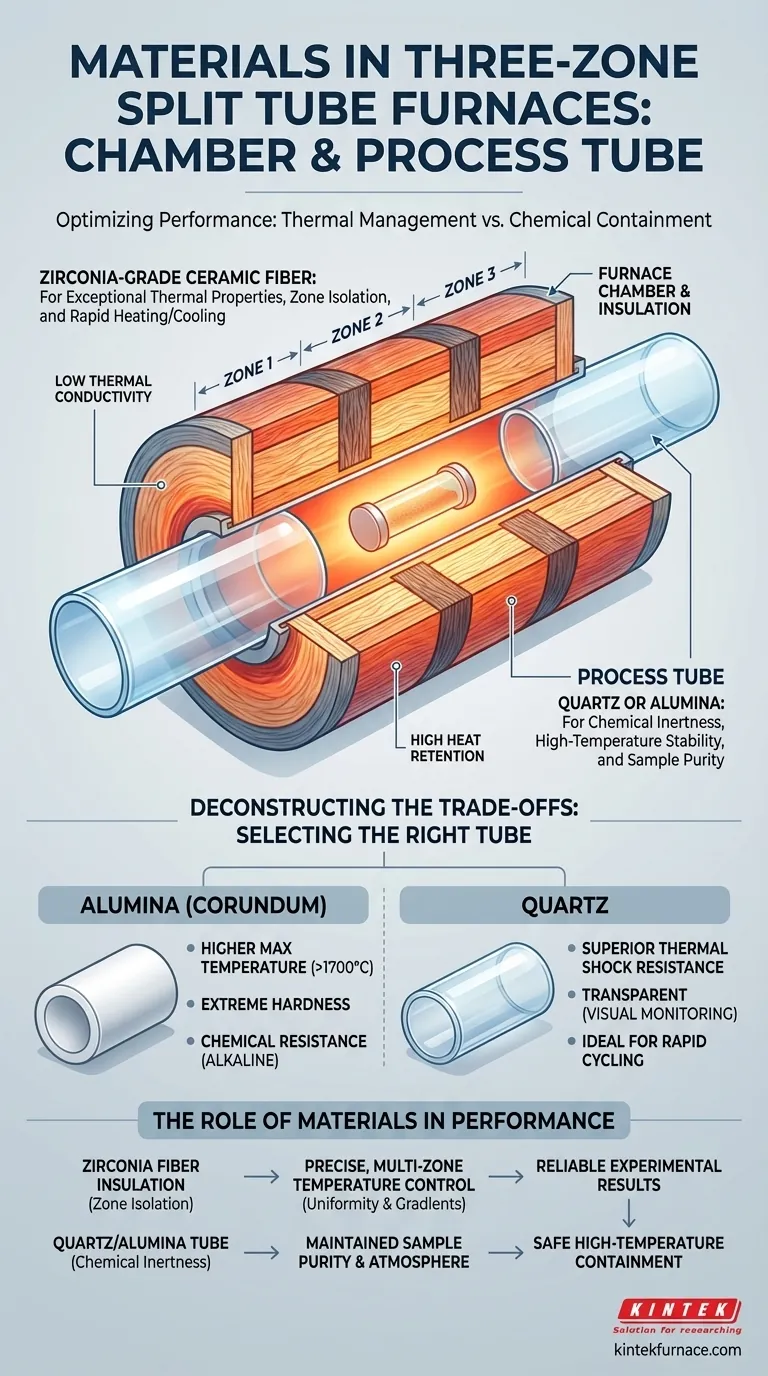

In a three-zone split tube furnace, the internal chamber and insulation are constructed from high-temperature, zirconia-grade ceramic fiber. This material is chosen for its exceptional thermal properties, which are critical for achieving the precise and uniform temperature control these furnaces are designed to provide.

The core distinction to understand is between the furnace body and the process tube. The furnace's internal chamber and insulation use zirconia-grade ceramic fiber for maximum heat retention, while the separate process tube holding your sample is typically made of quartz or alumina to ensure chemical inertness and high-temperature stability.

Deconstructing the Furnace: Chamber vs. Process Tube

To understand the material choices, it is crucial to differentiate between the furnace's structural components and the tube that contains the experimental sample.

The Furnace Chamber and Insulation

The furnace chamber is the heated cavity that houses the heating elements. This chamber, and the insulation surrounding it, forms the main body of the furnace.

Both of these components are made from a high-temperature, zirconia-grade ceramic fiber.

Why Zirconia-Grade Ceramic Fiber?

This material is chosen for its superior performance characteristics. Its primary benefit is its extremely low thermal conductivity, making it an outstanding insulator.

This ensures that heat is efficiently directed toward the process tube instead of being lost to the environment. This property is what enables rapid heating and cooling cycles and maintains excellent temperature stability.

The Process Tube

The process tube is a separate, often removable cylinder that slides into the center of the furnace. This tube is where the sample is placed and the desired atmosphere (e.g., vacuum, inert gas) is controlled.

The most common materials for process tubes are high-purity quartz and alumina (also known as corundum).

Why Quartz or Alumina for the Tube?

These materials are selected for their direct interaction with the high-temperature process. They are chemically inert, which is vital for preventing contamination of the sample.

Both quartz and alumina can withstand very high temperatures while maintaining their structural integrity, ensuring the experiment is contained safely and cleanly.

The Role of Materials in Performance

The specific materials are not arbitrary; they directly enable the furnace's primary function客户 of precise, multi-zone temperature control.

Uniformity Through Insulation

The effectiveness of a three-zone furnace hinges on its ability to minimize "cross-talk" between the heating zones. The high-quality zirconia-grade ceramic fiber insulation is critical for isolating these zones.

By preventing heat from bleeding excessively from one zone to another, the control system can accurately create a uniform temperature profile or a specific, controlled gradient across the sample.

Stability and Purity

The choice of an alumina or quartz process tube ensures that the controlled atmosphere and sample purity are maintained, even at extreme temperatures.

This separation of function—the ceramic fiber for thermal management and the quartz/alumina for chemical containment—is the foundation of a reliable high-temperature furnace.

Understanding the Trade-offs

While這些材料 are high-performance, they are not interchangeable. The choice, particularly for the process tube, involves trade-offs based on your specific application.

Alumina vs. Quartz Tubes

Alumina generally has a higher maximum operating temperature (often >1700°C) compared to quartz. It is extremely hard and resistant to chemical attack from alkaline substances.

Quartz, on the other hand, offers superior resistance to thermal shock, meaning it can handle rapid temperature changes better without cracking. It is also transparent, which can be useful for visual monitoring of a process.

Ceramic Fiber Durability

Zirconia-grade ceramic fiber is an excellent insulator but can be mechanically fragile. Over time and with repeated thermal cycles, the fibers can become brittle.

Care must be taken to avoid mechanical impact to the furnace interior to ensure the longevity of the insulation.

Making the Right Choice for Your Application

Your experimental goals should dictate your material selection, especially for the process tube.

- If your primary focus is maximum operating temperature (above ~1200°C): Choose an alumina process tube for its superior stability at extreme heat.

- If your primary focus is sample purity and rapid heating/cooling: A high-purity quartz process tube is ideal due to its excellent thermal shock resistance and inertness.

- If your primary focus is creating a precise temperature gradient: The furnace's zirconia-grade fiber insulation is the key enabling feature, ensuring the three-zone control system can function effectively.

Understanding this division of material responsibility is the key to achieving reliable and repeatable results in your high-temperature applications.

Summary Table:

| Component | Material | Key Properties |

|---|---|---|

| Chamber & Insulation | Zirconia-grade ceramic fiber | Low thermal conductivity, high heat retention, enables rapid heating/cooling |

| Process Tube | Quartz or Alumina | Chemically inert, high-temperature stability, thermal shock resistance (quartz), higher max temp (alumina) |

Unlock precision in your high-temperature experiments with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and reliability. Contact us today to discuss how our solutions can benefit your specific application!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision