In short, a ceramic dental furnace is expertly designed for processing conventional, delicate dental ceramics. These furnaces are the go-to tool for firing, glazing, and staining the porcelain layers on restorations like porcelain-fused-to-metal (PFM) crowns and certain all-ceramic crowns that do not require high-temperature processing.

The critical distinction to understand is that a standard ceramic furnace is a finishing tool for aesthetics, not a production tool for high-strength cores. It excels at the precise, low-temperature cycles needed to achieve lifelike color and translucency in porcelain, but it cannot perform the high-temperature sintering required for materials like zirconia.

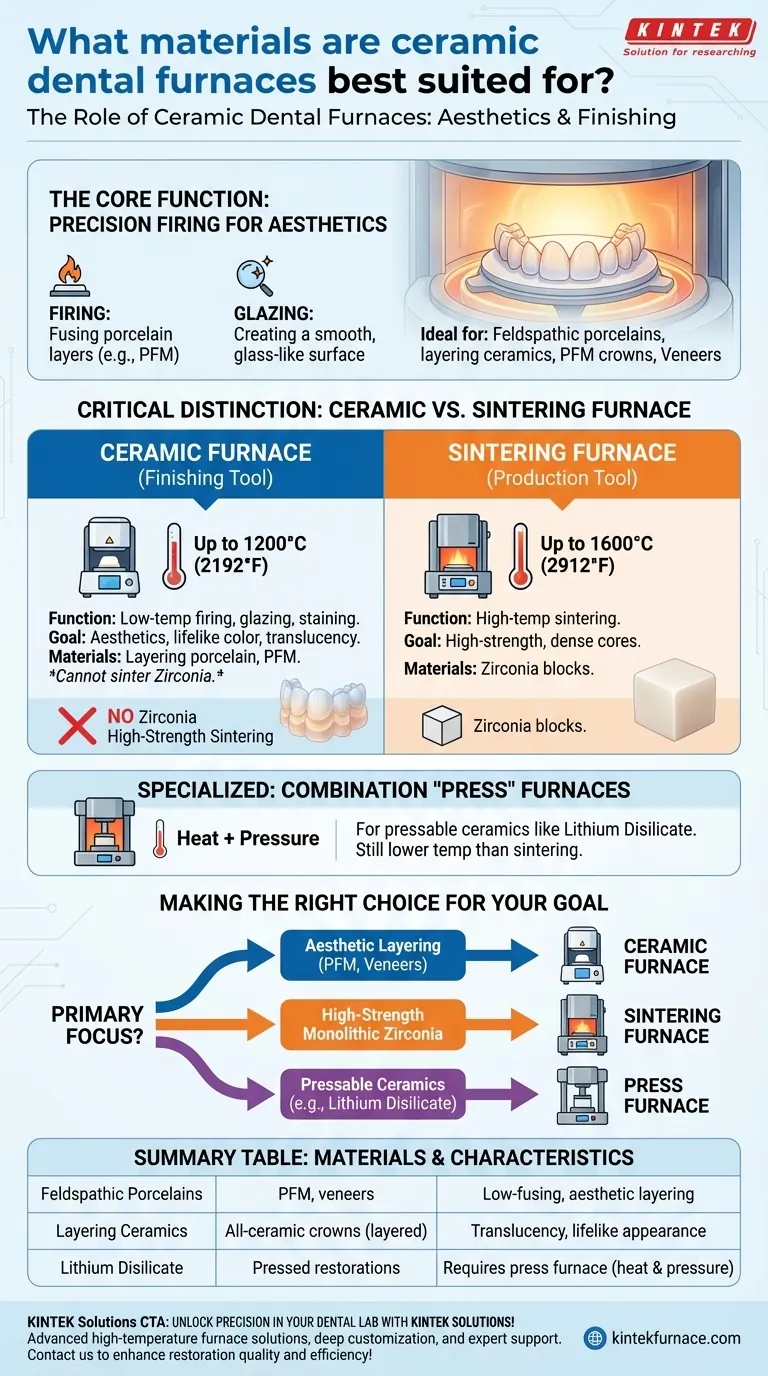

The Core Function: Precision Firing for Aesthetics

A ceramic furnace is not used to create the foundational strength of a restoration from a raw block. Instead, its role comes at the finishing stage, where artistry and precision are paramount.

What "Firing" and "Glazing" Mean

In this context, firing refers to heating layers of applied porcelain powder until they fuse together and bond to the underlying structure (either metal or a ceramic core).

Glazing is the final firing cycle, often at a specific temperature, that creates a smooth, glass-like, and non-porous surface on the restoration, mimicking the luster of natural tooth enamel.

Ideal Materials: Layering Porcelains

Ceramic furnaces are best suited for feldspathic porcelains and other low-fusing layering ceramics. These are the materials used to build up the final shape and color of a restoration.

This makes the furnace essential for fabricating:

- Porcelain-Fused-to-Metal (PFM) crowns and bridges

- Feldspathic porcelain veneers

- All-ceramic crowns that use a layering technique over a separate, pre-made core

Ceramic vs. Sintering Furnace: A Critical Distinction

Confusing a ceramic furnace with a sintering furnace is a common and costly mistake. They serve fundamentally different purposes and operate in completely different temperature ranges.

Temperature Range Defines Function

A ceramic furnace operates at a lower temperature range, typically up to 1200°C (2192°F). This is perfect for the delicate process of fusing porcelain layers without distorting the underlying structure.

A sintering furnace, by contrast, must reach much higher temperatures, often up to 1600°C (2912°F). This intense heat is necessary to transform a chalky, pre-milled zirconia block into a dense, monolithic, and high-strength final restoration.

The Role of "Combination" Press Furnaces

Some specialized ceramic furnaces are "combination" or "press" furnaces. In addition to firing cycles, they use pressure and heat to press materials like lithium disilicate into a mold. While they process a different material, they still operate at a lower temperature than a zirconia sintering furnace.

Understanding the Trade-offs

Choosing the right furnace is about matching the technology to the material and the desired outcome.

Limitation: No High-Strength Sintering

The primary limitation is clear: a standard ceramic furnace cannot sinter zirconia. Attempting to do so will fail to achieve the required density and strength, resulting in a clinically useless restoration.

Advantage: Unmatched Aesthetic Control

The furnace's lower temperature range and precise, programmable heating cycles give technicians unparalleled control over the final aesthetics. It allows for the multi-layered, polychromatic results that define high-end cosmetic dentistry.

Advantage: Cost and Footprint

Ceramic furnaces are generally more compact, more energy-efficient, and less expensive than their high-temperature sintering counterparts. This makes them a cost-effective and essential tool for any lab or practice focused on porcelain work.

Making the Right Choice for Your Goal

To select the correct equipment, you must first define the primary type of restorations you intend to produce.

- If your primary focus is aesthetic layering for PFM or feldspathic veneers: A traditional ceramic furnace is your essential tool for firing and glazing.

- If your primary focus is producing high-strength monolithic zirconia crowns: You absolutely require a high-temperature sintering furnace; a ceramic furnace cannot perform this task.

- If your primary focus is creating restorations from pressable ceramics (e.g., lithium disilicate): You need a specific "combination" or "press" furnace that integrates both heating and pressure capabilities.

Understanding this fundamental difference in function ensures you invest in the right technology to guarantee the quality and durability of every restoration.

Summary Table:

| Material Type | Best Use Cases | Key Characteristics |

|---|---|---|

| Feldspathic Porcelains | PFM crowns, feldspathic veneers | Low-fusing, ideal for color layering and aesthetics |

| Layering Ceramics | All-ceramic crowns with layering | Provides translucency and lifelike appearance |

| Lithium Disilicate (in press furnaces) | Pressed restorations | Requires combination furnaces with pressure and heat |

Unlock Precision in Your Dental Lab with KINTEK Solutions! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're working with aesthetic porcelains or need tailored furnace setups, we deliver reliable performance and expert support. Contact us today to enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations