At its core, the split tube furnace is a preferred choice because its hinged design fundamentally solves the logistical challenges of sample handling in advanced applications. This unique structure allows for direct placement and observation of samples within the heating chamber, offering a level of accessibility and efficiency that standard solid-tube furnaces cannot match.

The defining advantage of a split tube furnace isn't just about heating; it's about workflow. Its design prioritizes rapid sample access and easy integration with complex test equipment, making it an indispensable tool for accelerating research and optimizing delicate processes.

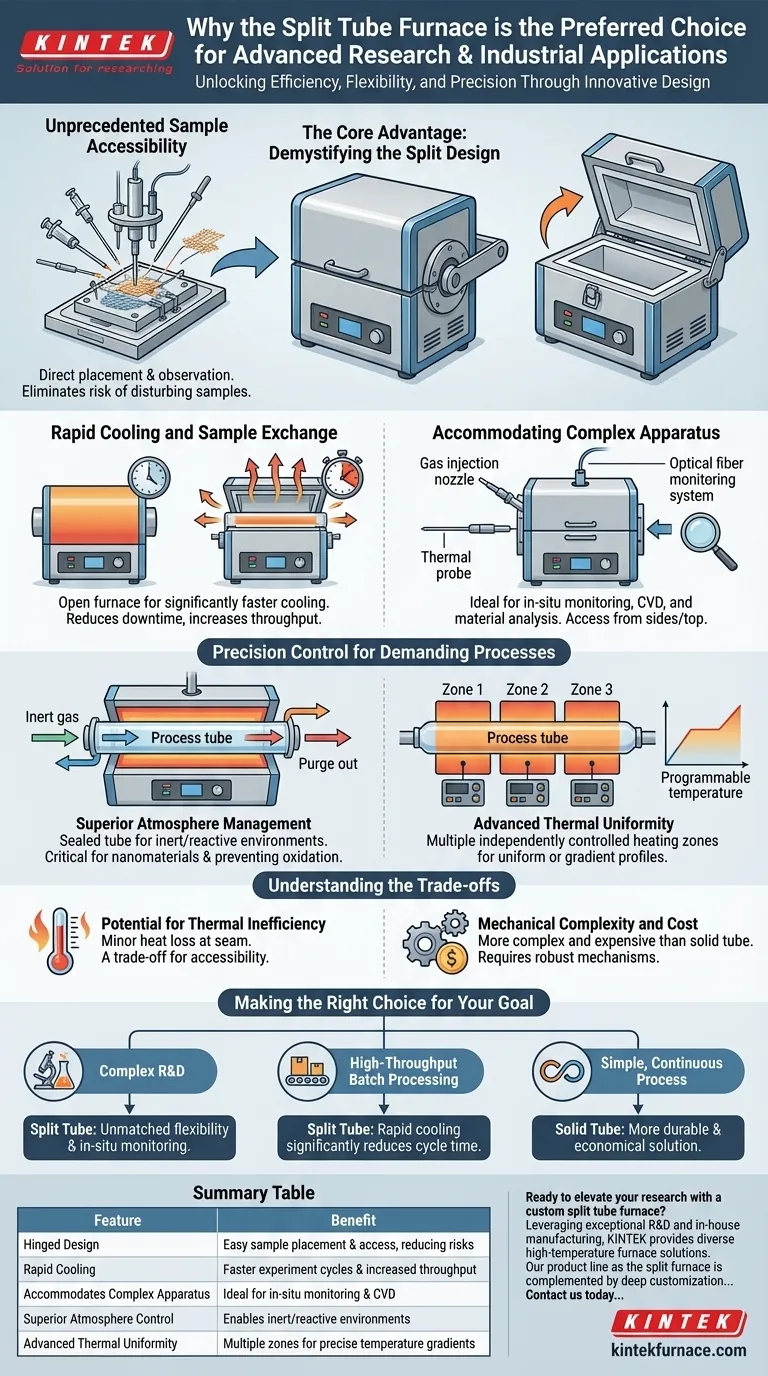

The Core Advantage: Demystifying the Split Design

A standard tube furnace is a solid cylinder. To use it, you must slide your process tube and sample in from one end. A split tube furnace, however, is built with a clamshell-style body that hinges open along its length.

Unprecedented Sample Accessibility

The ability to open the furnace transforms how you work. You can place a process tube with a delicate or bulky sample assembly directly onto the bottom half of the furnace before closing the top.

This eliminates the risk of disturbing the sample, which is a common problem when sliding complex setups through a long, solid furnace tube.

Rapid Cooling and Sample Exchange

Once a heating cycle is complete, the furnace can be opened. This exposes the process tube to ambient air, allowing for significantly faster cooling compared to a solid furnace that must cool passively.

For processes like thermal quenching or simply running multiple batches, this rapid cooling drastically reduces downtime between experiments, directly increasing laboratory or production throughput.

Accommodating Complex Apparatus

The split design is ideal for experiments that require in-situ monitoring. Probes, gas injection nozzles, or other diagnostic tools can be inserted directly into the process tube from the side or top.

This is nearly impossible with a solid tube furnace, which limits access points to the ends of the tube. This makes the split tube essential for advanced chemical vapor deposition (CVD) and material analysis.

Precision Control for Demanding Processes

Beyond its mechanical design, the split tube furnace offers the high degree of control necessary for advanced materials science and semiconductor manufacturing.

Superior Atmosphere Management

Like all high-quality tube furnaces, the split design allows a process tube to be sealed and purged with a specific gas. This provides exceptional atmosphere control, enabling work in inert (Argon, Nitrogen) or reactive environments.

This capability is critical for synthesizing nanomaterials, annealing semiconductors, and preventing oxidation in sensitive materials.

Advanced Thermal Uniformity

These furnaces are often available with multiple, independently controlled heating zones along their length.

This feature allows operators to either create an exceptionally uniform temperature zone for consistent processing or to program a specific temperature gradient across the sample, a requirement for certain crystal growth and chemical transport experiments.

Understanding the Trade-offs

While powerful, the split tube design is not universally superior. Its advantages come with specific considerations.

Potential for Thermal Inefficiency

The seam where the two halves of the furnace meet can be a source of minor heat loss compared to the seamless insulation of a solid-body furnace.

While modern designs minimize this, it is a fundamental trade-off for the accessibility the split design provides.

Mechanical Complexity and Cost

The hinges, latches, and alignment mechanisms make a split tube furnace inherently more complex and expensive than a comparable solid tube model.

For applications that do not require frequent sample access or rapid cooling, a simpler solid tube furnace may be a more robust and cost-effective choice.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the specific demands of your process.

- If your primary focus is complex R&D: The split tube furnace is the superior choice for its unmatched flexibility in sample setup and in-situ monitoring.

- If your primary focus is high-throughput batch processing: The rapid cooling capability of a split tube furnace will significantly reduce cycle time and increase productivity.

- If your primary focus is a simple, continuous process with minimal changeover: A standard solid-tube furnace may offer a more durable and economical solution.

Ultimately, the split tube furnace empowers you to perform complex thermal processes with greater speed, precision, and ease.

Summary Table:

| Feature | Benefit |

|---|---|

| Hinged Design | Easy sample placement and access, reducing handling risks |

| Rapid Cooling | Faster experiment cycles and increased throughput |

| Accommodates Complex Apparatus | Ideal for in-situ monitoring and CVD applications |

| Superior Atmosphere Control | Enables work in inert or reactive environments |

| Advanced Thermal Uniformity | Multiple heating zones for precise temperature gradients |

Ready to elevate your research with a custom split tube furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and precision!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision