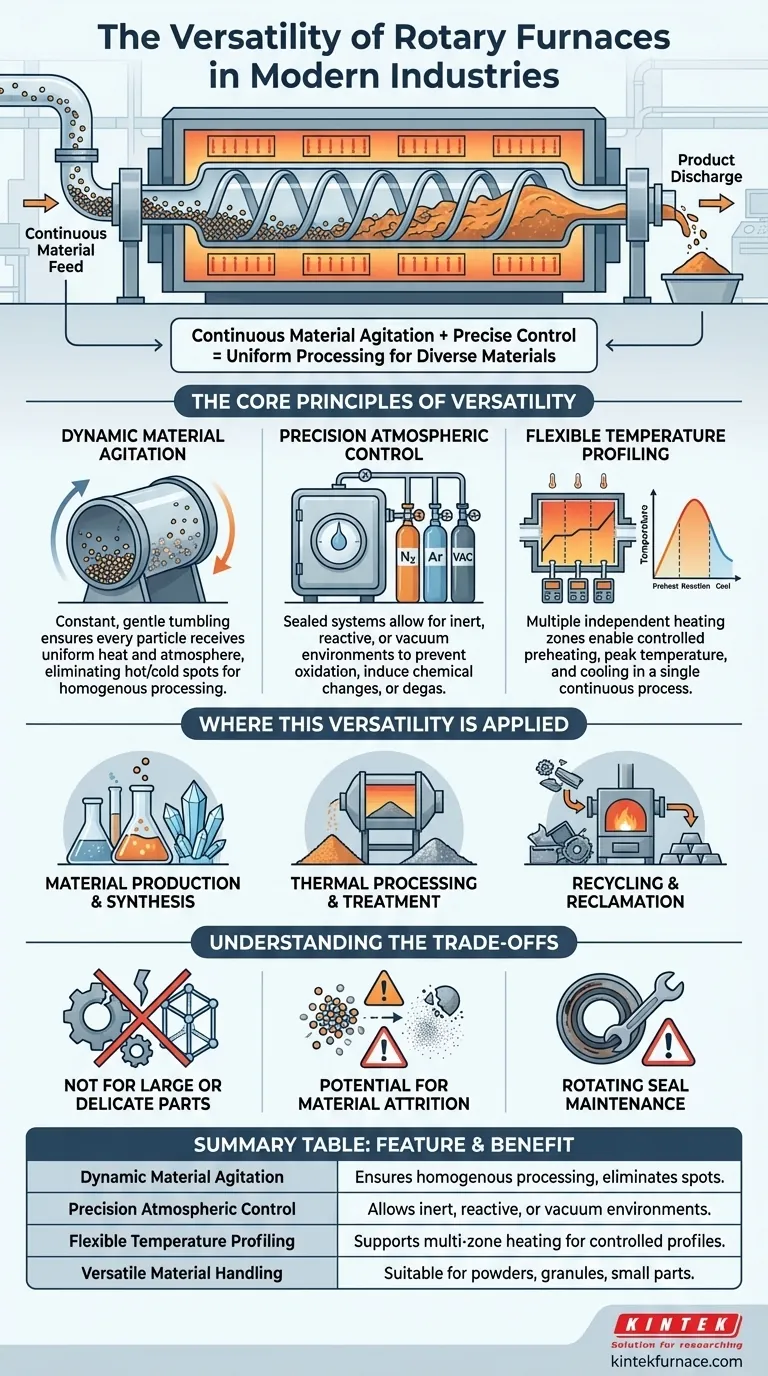

At their core, rotary furnaces are versatile because they combine continuous material agitation with precise control over temperature and atmosphere. This unique combination allows a single piece of equipment to handle an exceptionally wide range of materials—from powders and granules to small parts—and execute diverse thermal processes like drying, reacting, and heat-treating with high consistency.

The challenge for many industries is achieving uniform thermal processing across different materials and batch sizes. Rotary furnaces solve this not just by heating, but by actively moving the material through a tightly controlled environment, ensuring every particle receives the same treatment.

The Core Principles of Versatility

The adaptability of a rotary furnace stems from three fundamental operating principles working in concert. Understanding these is key to seeing why they are used in so many different applications.

Dynamic Material Agitation

The defining feature is the rotation of the central tube or retort. This constant, gentle tumbling action is critical for uniformity.

Unlike a static furnace where material at the bottom heats differently than material at the top, the rotation ensures every particle is continuously exposed to the heat source and the internal atmosphere. This guarantees homogenous processing and eliminates hot or cold spots.

Precision Atmospheric Control

Many modern rotary furnaces are designed as sealed systems. This allows for the complete evacuation of air and the introduction of specific process gases.

This control enables a vast range of chemical and physical changes. You can run processes in an inert atmosphere (like nitrogen or argon) to prevent oxidation, a reactive atmosphere to induce chemical changes (like carburizing), or a vacuum for degassing.

Flexible Temperature Profiling

These furnaces are not limited to a single temperature. They can be engineered with multiple, independently controlled heating zones along the length of the tube.

This allows for precise temperature profiling. A material can be gently preheated in the first zone, brought to a peak reaction temperature in the middle, and then cooled in a controlled manner in the final zone, all within one continuous process.

Where This Versatility Is Applied

The combination of these principles makes rotary furnaces indispensable across several key industrial sectors.

Material Production and Synthesis

For creating advanced materials, catalysts, or specialty chemicals, the ability to control both temperature and atmosphere while mixing is paramount. The furnace becomes a chemical reactor, not just a heater.

Thermal Processing and Treatment

This is the broadest category of use. Applications include drying bulk solids, calcining minerals (heating to drive off impurities), aging metal powders, and performing controlled oxidation or reduction of materials.

Recycling and Reclamation

In the metals industry, rotary furnaces are used to reclaim valuable materials from scrap. The tumbling action helps separate metals from contaminants, while the controlled heat efficiently melts the target material for recovery.

Understanding the Trade-offs

Despite their flexibility, rotary furnaces are not a universal solution. Understanding their limitations is critical for proper application.

Not Ideal for Large or Delicate Parts

The design is optimized for granular, powdered, or small, uniformly shaped parts that can tumble freely. Large, single components or extremely delicate structures that could be damaged by the tumbling action are not suitable.

Potential for Material Attrition

The mechanical tumbling action can cause friable or brittle materials to break down, creating unwanted dust or changing the particle size distribution. This must be a consideration for materials sensitive to mechanical stress.

Maintenance of Rotating Seals

The points where the rotating tube meets the stationary ends of the furnace require specialized seals. These seals are critical for maintaining atmospheric integrity but are wear components that demand regular inspection and maintenance.

Making the Right Choice for Your Process

Selecting a rotary furnace depends entirely on the nature of your material and the goals of your thermal process.

- If your primary focus is high-throughput, uniform processing of powders or granules: A rotary furnace is an excellent choice due to its continuous motion and homogenous heating.

- If your primary focus is a chemical reaction requiring a specific atmosphere: The sealed retort design provides the precise atmospheric control needed for processes like reduction or carburization.

- If your primary focus is R&D with a wide variety of materials: The adaptability of a smaller, lab-scale rotary tube furnace allows you to test numerous materials and processes with a single device.

Ultimately, a rotary furnace is the right tool when your process benefits from combining dynamic material movement with precise environmental control.

Summary Table:

| Feature | Benefit |

|---|---|

| Dynamic Material Agitation | Ensures homogenous processing and eliminates hot/cold spots |

| Precision Atmospheric Control | Allows inert, reactive, or vacuum environments for varied chemical processes |

| Flexible Temperature Profiling | Supports multi-zone heating for controlled preheating, reaction, and cooling |

| Versatile Material Handling | Suitable for powders, granules, and small parts in continuous operations |

Ready to enhance your lab's thermal processing capabilities? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our rotary furnaces can optimize your material synthesis, thermal treatment, or recycling processes with superior uniformity and control!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules