At their core, rotary furnaces are considered environmentally friendly due to a combination of high thermal efficiency, superior material processing, and compatibility with advanced emission control systems. Their unique rotating design ensures that materials are heated uniformly and processed completely, which simultaneously maximizes energy use, minimizes material waste, and allows for the effective capture of harmful byproducts.

The environmental advantage of a rotary furnace is not from a single feature, but from its fundamental design. The continuous rotation of the furnace tube is the mechanism that enables exceptional energy efficiency, high material recovery rates, and effective pollution control.

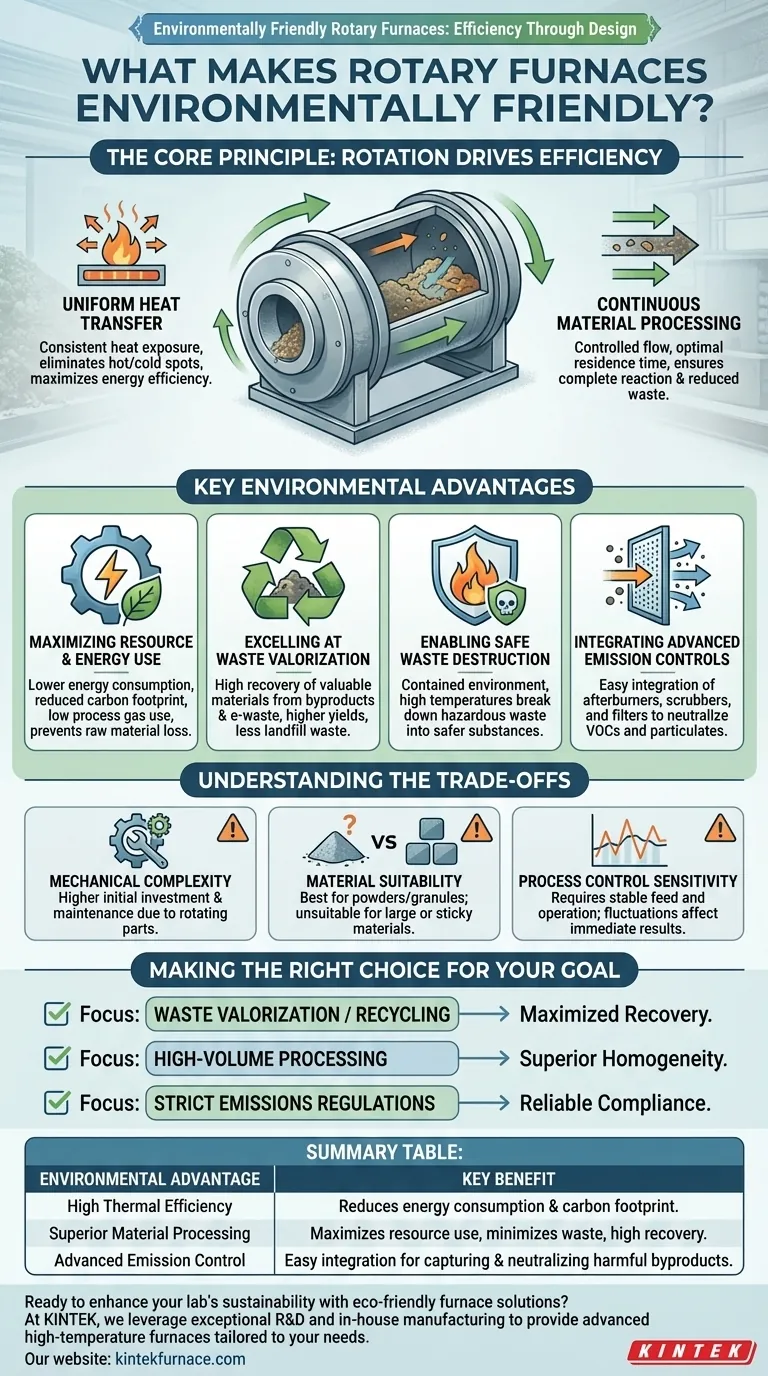

The Core Principle: How Rotation Drives Efficiency

The defining characteristic of a rotary furnace is its long, cylindrical chamber (or tube) that is slightly inclined and rotates slowly. This design is the foundation of its environmental performance.

Uniform Heat Transfer

The constant tumbling motion ensures every particle of the material is consistently exposed to the heat source. This eliminates hot and cold spots common in static furnaces.

This uniformity means energy is transferred into the material with maximum efficiency, preventing wasted thermal output and reducing overall fuel or electricity consumption.

Continuous Material Processing

Material is fed into the higher end of the inclined tube and gradually moves toward the lower end as it rotates. This creates a continuous, controlled flow.

This process ensures all material spends the optimal amount of time in the furnace, leading to complete reactions and preventing unprocessed material from becoming waste.

Key Environmental Advantages Explained

The efficient design of a rotary furnace translates directly into tangible environmental benefits, from reducing waste to controlling air pollution.

Maximizing Resource and Energy Use

Because of the uniform heating, rotary furnaces achieve the desired process temperature using less energy. This directly lowers the carbon footprint of the operation.

The design also allows for very low process gas consumption and includes measures that prevent raw material from scattering, ensuring that valuable inputs are not lost.

Excelling at Waste Valorization

Rotary furnaces are highly effective at recovering valuable materials from various waste streams, including industrial byproducts and e-waste.

Their ability to process materials completely means higher yields and less valuable material ending up in a landfill. This turns a waste liability into a valuable resource.

Enabling Safe Waste Destruction

The contained and controlled environment of a rotary furnace is ideal for safely processing and destroying hazardous waste.

High temperatures and controlled residence times ensure the complete breakdown of harmful organic compounds, converting them into safer, more manageable substances.

Integrating Advanced Emission Controls

The furnace's single-point exhaust stream makes it straightforward to integrate advanced emissions control systems, such as afterburners, scrubbers, and filters.

These systems capture and neutralize harmful outputs like volatile organic compounds (VOCs) and particulates before they can be released into the atmosphere.

Understanding the Trade-offs

While highly effective, rotary furnaces are not a universal solution. Understanding their limitations is critical for making an informed decision.

Mechanical Complexity

The rotating drum, seals, and drive system introduce mechanical complexity not present in static furnaces. This can lead to higher initial investment and more demanding maintenance schedules to ensure reliability.

Material Suitability

Rotary furnaces excel at processing powders, granules, and small, loose materials. They are generally not suitable for very large, solid objects or materials that might melt and stick to the furnace walls, which could disrupt the tumbling action.

Process Control Sensitivity

While offering precise control, the continuous nature of the process means that fluctuations in feed rate or material composition can have immediate effects downstream. Stable and consistent operation is key to achieving optimal results.

Making the Right Choice for Your Goal

To determine if a rotary furnace is the right choice, consider your primary operational objective.

- If your primary focus is waste valorization or recycling: A rotary furnace is an exceptional choice for maximizing the recovery of valuable materials from diverse waste streams.

- If your primary focus is high-volume powder and granule processing: The uniform heating provided by the rotating design ensures superior product homogeneity and quality at a continuous throughput.

- If your primary focus is meeting strict emissions regulations: The design's compatibility with advanced control systems makes it a reliable solution for safely processing hazardous materials and minimizing air pollution.

Ultimately, choosing a rotary furnace is a strategic decision that aligns operational efficiency with environmental responsibility.

Summary Table:

| Environmental Advantage | Key Benefit |

|---|---|

| High Thermal Efficiency | Reduces energy consumption and carbon footprint through uniform heating. |

| Superior Material Processing | Maximizes resource use, minimizes waste, and enables high recovery rates. |

| Advanced Emission Control | Allows easy integration of systems to capture and neutralize harmful byproducts. |

Ready to enhance your lab's sustainability with eco-friendly furnace solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Whether you're focused on waste valorization, high-volume processing, or strict emissions compliance, our solutions can help you achieve superior efficiency and environmental responsibility.

Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs