The defining characteristic of a polymer PTC heating element is its intrinsic ability to self-regulate its temperature. Unlike traditional heaters that require external thermostats and sensors, a PTC heater's resistance automatically increases dramatically when it reaches a specific temperature, effectively throttling its own power consumption and preventing overheating. This behavior is a fundamental property of the material itself.

The core insight is that polymer PTC technology embeds safety and control directly into the heating element. This shifts the design paradigm from managing heat with external components to using a material that intelligently manages itself, leading to simpler, safer, and more reliable systems.

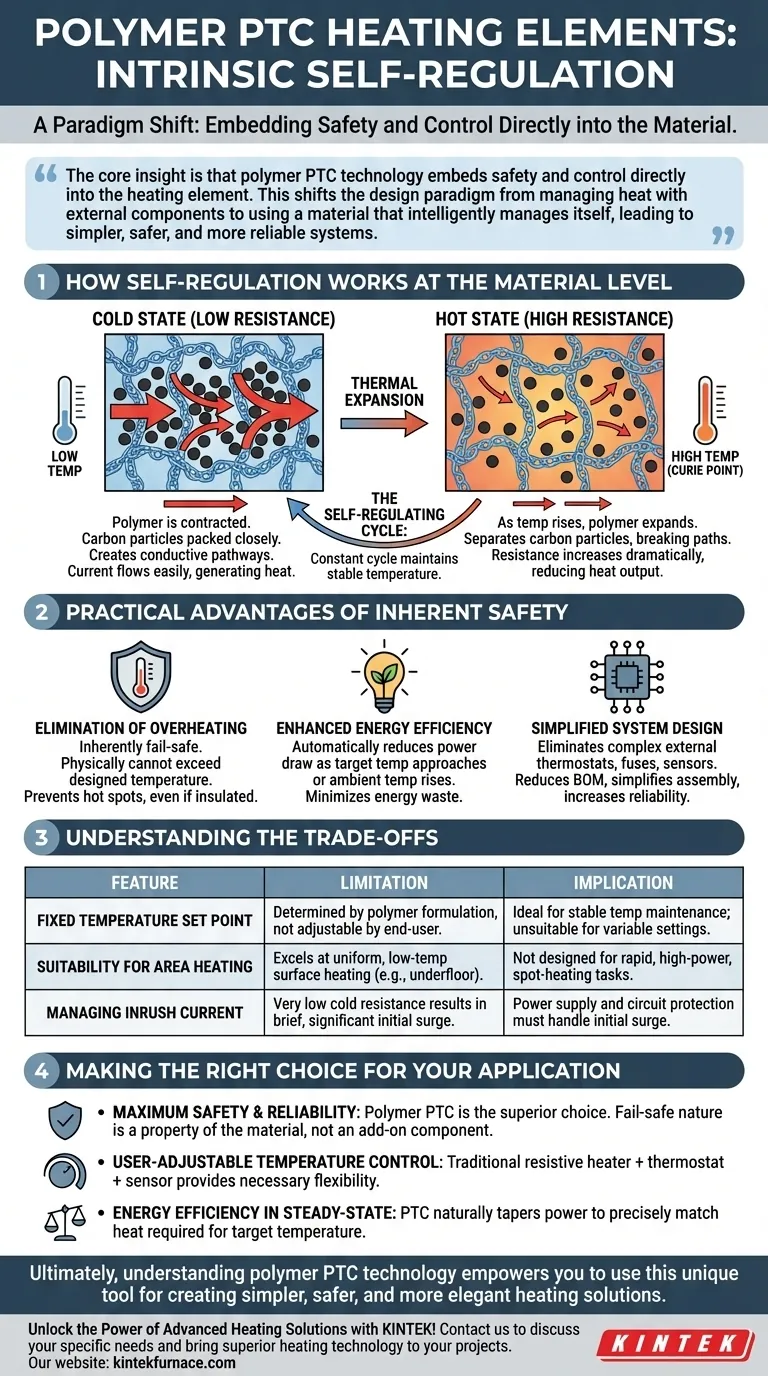

How Self-Regulation Works at the Material Level

The "magic" of a polymer PTC heater isn't magic at all, but rather a clever application of material science. The element is a composite material, not a simple resistive wire.

The Polymer-Carbon Matrix

At its core, the heater is made of a crystalline polymer blended with conductive carbon black particles. These particles are distributed throughout the polymer matrix.

Cold State: Low Resistance

When the material is cold, the polymer is in a contracted state. The carbon particles are packed closely together, forming numerous conductive pathways through the material. This creates a state of low electrical resistance, allowing current to flow easily and generate heat.

Hot State: High Resistance

As the element heats up to its designed "switch" temperature (also known as the Curie temperature), the crystalline polymer undergoes a phase change and expands rapidly. This thermal expansion separates the carbon particles, breaking the conductive pathways. The material's resistance can increase by several orders of magnitude in just a few degrees, drastically reducing current flow and heat output.

The Self-Regulating Cycle

The heater then cools slightly, causing the polymer to contract and re-form some conductive paths. This allows heating to resume. This constant cycle allows the PTC element to maintain a stable temperature without any external controls.

The Practical Advantages of Inherent Safety

This unique self-regulating property translates directly into significant design and performance benefits. It solves the fundamental problem of controlling heat in a simple and robust way.

Elimination of Overheating

Because the heater physically cannot exceed its designed temperature, it is inherently fail-safe. Even if a section of the heater becomes insulated or blocked, only that specific area will increase its resistance and stop heating, preventing dangerous hot spots.

Enhanced Energy Efficiency

True efficiency comes from using only the energy required. A PTC heater automatically reduces its power draw as it approaches its target temperature and as the ambient temperature rises, preventing the energy waste common in simple on/off systems that overshoot their setpoints.

Simplified System Design

The built-in safety mechanism eliminates the need for complex and failure-prone external components like thermal fuses, thermostats, or temperature sensors. This reduces the bill of materials (BOM), simplifies assembly, and increases the overall reliability of the final product.

Understanding the Trade-offs

No technology is a universal solution. The unique properties of polymer PTC heaters come with specific limitations that are critical to understand for proper application.

Fixed Temperature Set Point

The operating temperature of a PTC heater is determined by the specific polymer formulation used during its manufacturing. It cannot be adjusted by the end-user. This makes it ideal for maintaining a single, stable temperature but unsuitable for applications requiring variable heat settings.

Suitability for Area Heating

Polymer PTC elements excel at providing uniform, low-temperature heat over a surface area, such as in underfloor heating or de-icing applications. They are generally not designed for the rapid, high-power, spot-heating tasks where traditional coil heaters excel.

Managing Inrush Current

In its cold state, the PTC element has very low resistance. When power is first applied, this can result in a brief but significant inrush current. The power supply and circuit protection must be designed to handle this initial surge without tripping.

Making the Right Choice for Your Application

Selecting the correct heating technology requires aligning its core strengths with your primary design goal.

- If your primary focus is maximum safety and reliability: Polymer PTC is the superior choice, as its fail-safe nature is a property of the material itself, not an add-on component.

- If your primary focus is user-adjustable temperature control: A traditional resistive heater paired with a thermostat and sensor provides the flexibility that a fixed-temperature PTC cannot.

- If your primary focus is energy efficiency in a steady-state system: PTC technology is highly effective, as it naturally tapers its power consumption to precisely match the heat required to maintain its target temperature.

Ultimately, understanding the fundamental principle of polymer PTC technology empowers you to use this unique tool for creating simpler, safer, and more elegant heating solutions.

Summary Table:

| Feature | Description |

|---|---|

| Self-Regulation | Automatically adjusts resistance to prevent overheating without external controls |

| Safety | Inherently fail-safe, eliminating hot spots and reducing fire risks |

| Energy Efficiency | Reduces power draw as temperature stabilizes, minimizing waste |

| Design Simplicity | No need for thermostats or sensors, lowering BOM and improving reliability |

| Fixed Temperature | Operates at a preset Curie temperature, ideal for stable heating |

| Application Suitability | Best for uniform, low-temperature area heating like underfloor systems |

| Inrush Current | Requires handling initial power surge due to low cold-state resistance |

Unlock the Power of Advanced Heating Solutions with KINTEK!

Are you designing for safety-critical applications or seeking energy-efficient, reliable heating systems? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need fail-safe polymer PTC elements or tailored furnace designs, we deliver innovative solutions that enhance efficiency and reliability.

Contact us today to discuss how we can support your specific needs and bring superior heating technology to your projects!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs