At its core, graphite's versatility in vacuum furnaces comes from a unique combination of properties that other materials cannot match. It offers exceptional strength and stability at extreme temperatures, superior thermal conductivity, chemical inertness, and the practical ability to be easily machined into complex shapes.

The challenge of a vacuum furnace is finding a material that can not only survive but also perform predictably in an environment of extreme heat and chemical reactivity. Graphite is the solution because its thermal, mechanical, and chemical properties work in concert to provide stability, efficiency, and design flexibility where metals would melt, warp, or react.

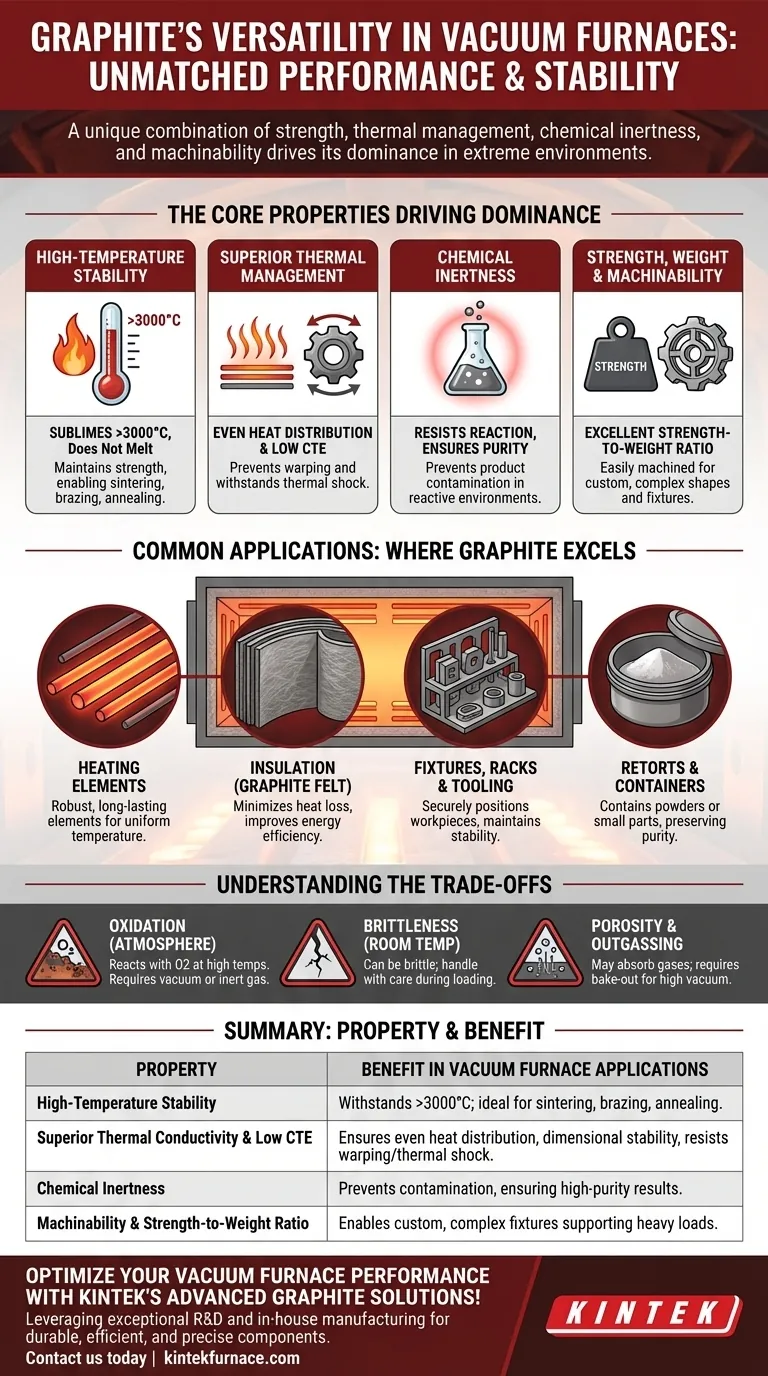

The Core Properties Driving Graphite's Dominance

To understand why graphite is the default choice, we must look at how its individual characteristics solve specific engineering problems inside a furnace.

Unmatched High-Temperature Stability

Graphite does not melt at atmospheric pressure; instead, it sublimes (turns directly into a gas) at temperatures exceeding 3,000°C.

This incredibly high temperature resistance allows vacuum furnaces to operate reliably for demanding processes like sintering, brazing, and annealing, where most metals would have failed. It maintains its mechanical strength at temperatures where even refractory metals begin to soften.

Superior Thermal Management

Graphite's thermal properties are key to furnace performance and longevity. Its high thermal conductivity ensures that heating elements distribute heat evenly, promoting uniform temperature zones within the furnace.

Simultaneously, its low coefficient of thermal expansion (CTE) means that fixtures, trays, and structural components do not significantly expand, warp, or distort when heated. This dimensional stability is critical for positioning workpieces precisely.

This combination also gives it strong resistance to thermal shock, allowing it to endure rapid heating and cooling cycles without cracking or failing.

Chemical Inertness in a Reactive Environment

At the high temperatures found in a vacuum furnace, materials become far more reactive. Graphite's chemical resistance is a significant advantage.

It is chemically inert and will not react with or contaminate the products being heat-treated. This ensures high purity for sensitive materials and predictable results for metallurgical processes.

Strength, Weight, and Machinability

Graphite offers an excellent strength-to-weight ratio, especially at high temperatures. It can support heavy loads without bending or deforming.

Crucially, it is also relatively easy and cost-effective to machine. This allows for the creation of complex and custom-designed components, from intricate heating elements to bespoke fixtures and racks for holding uniquely shaped parts.

Common Applications: Where Graphite Excels

These properties translate directly into the components that make up a modern vacuum furnace's hot zone.

Heating Elements

Graphite's high electrical and thermal conductivity, combined with its temperature resistance, makes it an ideal material for robust, long-lasting heating elements that provide excellent temperature uniformity.

Insulation (Graphite Felt)

In the form of felt or rigid board, graphite serves as highly effective high-temperature insulation. It minimizes heat loss, improving the furnace's energy efficiency and protecting the outer furnace body.

Fixtures, Racks, and Tooling

This is where graphite's machinability and low CTE shine. Trays, racks, baskets, and custom holders are all made from graphite to securely position workpieces during processing, ensuring they remain stable even through extreme temperature changes.

Retorts and Containers

For processes that require containing powders or small parts, graphite retorts and crucibles are used. Their chemical inertness prevents any reaction with the contained material, preserving its purity.

Understanding the Trade-offs

While highly versatile, graphite is not without limitations that dictate its proper use.

Oxidation in Atmosphere

Graphite's primary weakness is its reaction with oxygen at high temperatures. This is precisely why it is used in vacuum or inert gas atmospheres. Exposing a hot graphite component to air will cause it to rapidly oxidize and degrade.

Brittleness at Room Temperature

Compared to metals, solid graphite can be brittle and must be handled with care to avoid chipping or cracking, particularly during furnace loading and unloading.

Porosity and Outgassing

Depending on the grade, graphite can be porous and absorb moisture and other gases from the atmosphere. In high-vacuum applications, this can lead to outgassing as the furnace heats up, requiring proper bake-out procedures to achieve the target vacuum level.

Making the Right Choice for Your Goal

Selecting the right grade and design of graphite components is critical for optimizing your furnace operations.

- If your primary focus is process purity and repeatability: Prioritize high-purity, dense graphite grades for fixtures and retorts to minimize outgassing and prevent product contamination.

- If your primary focus is complex part processing: Leverage graphite's excellent machinability to design custom fixtures that provide optimal support and heat exposure for intricate components.

- If your primary focus is rapid cycle times: Select components designed with graphite's thermal shock resistance and high conductivity in mind to withstand aggressive heating and cooling ramps.

Ultimately, understanding these properties allows you to leverage graphite not just as a material, but as a strategic tool for optimizing your high-temperature processes.

Summary Table:

| Property | Benefit in Vacuum Furnace Applications |

|---|---|

| High-Temperature Stability | Withstands temperatures >3000°C without melting; ideal for sintering, brazing, and annealing. |

| Superior Thermal Conductivity & Low CTE | Ensures even heat distribution and dimensional stability, resisting warping and thermal shock. |

| Chemical Inertness | Prevents contamination of sensitive materials, ensuring high-purity results. |

| Machinability & Strength-to-Weight Ratio | Enables custom, complex fixtures and tooling that support heavy loads at high temperatures. |

Optimize your vacuum furnace performance with KINTEK's advanced graphite solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace components tailored to their unique needs. Our graphite expertise ensures durability, efficiency, and precision for your most demanding processes.

Contact us today to discuss how our custom heating elements, insulation, and fixtures can enhance your lab's capabilities!

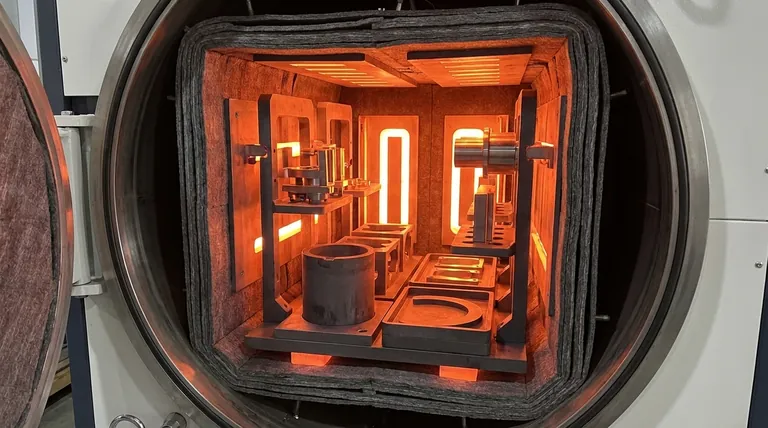

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment