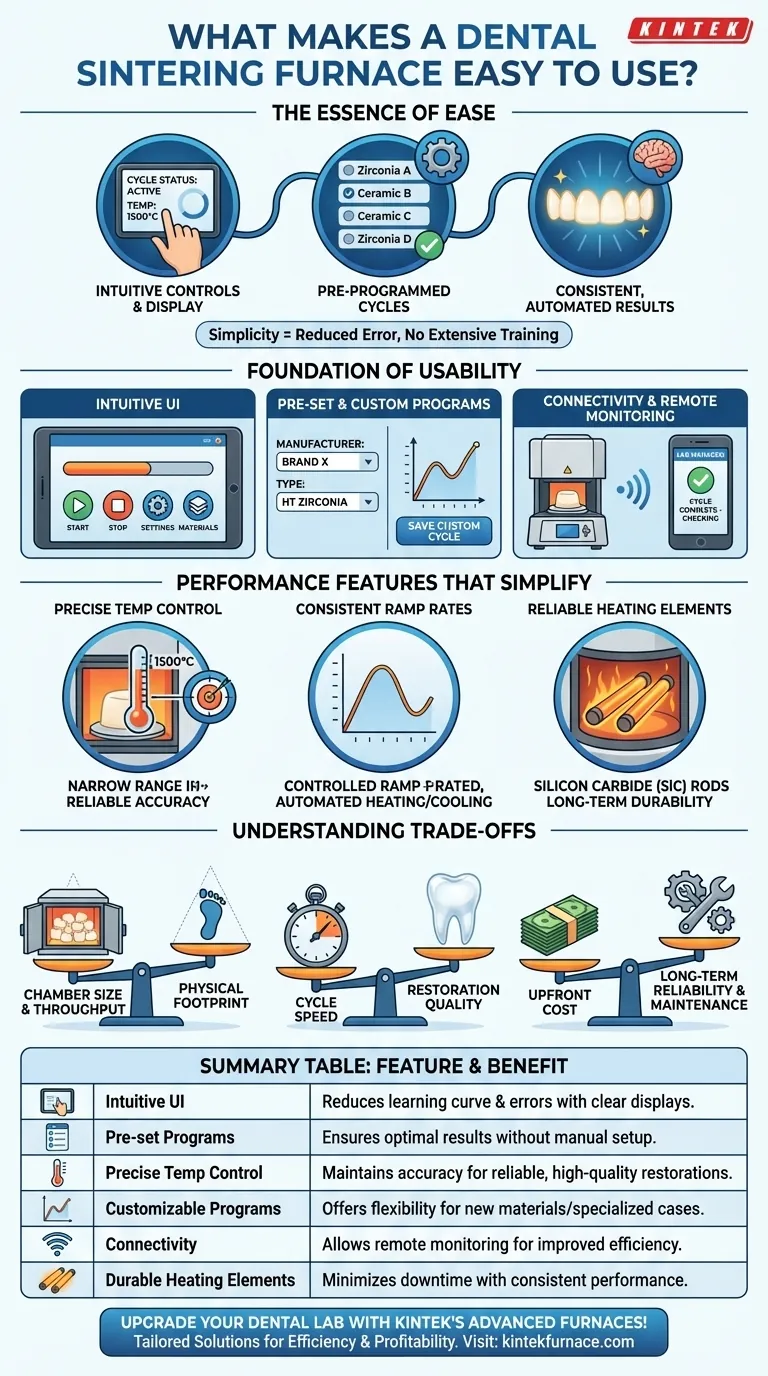

In essence, a dental sintering furnace is easy to use when it features intuitive controls, a clear display, and pre-programmed firing cycles. These elements work together to simplify daily operation, reduce the potential for human error, and ensure consistent, high-quality results without requiring extensive technical training for every user.

True ease of use, however, extends beyond a simple interface. It is achieved when a furnace reliably automates complex processes, allowing technicians to trust the machine to produce perfect restorations consistently, which saves time, reduces waste, and increases lab profitability.

The Foundation of Usability: Control and Programming

The primary driver of user-friendliness is how a technician interacts with the furnace. A well-designed system removes guesswork and streamlines the most common tasks, making the entire process feel effortless and predictable.

Intuitive User Interface (UI)

A furnace should not require a manual for basic operation. Ease of use begins with a clear, high-contrast display that presents critical information—like cycle status, temperature, and remaining time—at a glance.

Controls, whether touchscreen or physical buttons, must be logically laid out. This simplicity minimizes the learning curve and reduces the likelihood of inputting incorrect parameters.

Pre-set and Customizable Programs

Modern furnaces come with pre-programmed cycles for the most common zirconia and ceramic materials. This is a crucial feature for ease of use.

A technician can simply select the material manufacturer and type, and the furnace automatically runs the validated heating and cooling cycle. This ensures optimal results and material integrity every time.

The ability to create and save custom programs also enhances usability, providing flexibility for new materials or specialized cases without a complicated setup process.

Connectivity and Remote Monitoring

Advanced furnaces offer connectivity options, allowing lab managers or technicians to monitor cycle progress from a computer or mobile device.

This feature provides peace of mind and improves workflow efficiency, as you don't need to be physically present to know when a cycle is complete.

Performance Features That Simplify Your Workflow

Ease of use is meaningless if the final product is subpar. Key performance characteristics directly contribute to a simpler, more reliable workflow by ensuring the furnace does its job correctly without constant oversight.

Precise Temperature Control

A furnace that can hold a specific temperature with high accuracy is fundamentally easier to work with. It builds trust.

When you can rely on the furnace to hit and maintain the target temperature (typically 1400°C to 1600°C), you eliminate the need to adjust for inconsistencies, leading to predictable, high-quality restorations.

Consistent Heating and Cooling Rates

The ramp rate—how quickly the furnace heats up and cools down—is critical for the final strength and aesthetics of a ceramic restoration.

An easy-to-use furnace manages these rates automatically as part of its pre-set programs. This removes a significant variable from the technician's hands, simplifying the path to a perfect result.

Reliable Heating Elements

The quality of the heating elements, preferably silicon carbide (SiC) or other high-purity types, is a cornerstone of long-term ease of use.

Durable, high-quality elements ensure consistent performance over thousands of hours. This means less downtime for maintenance and replacement, fewer failed cycles, and a more dependable production environment.

Understanding the Trade-offs

Choosing a furnace involves balancing competing priorities. What seems "easy" in one area may introduce complications in another.

Chamber Size vs. Footprint

A larger chamber allows you to sinter more restorations at once, increasing throughput. However, it also means a larger physical footprint and potentially higher energy consumption.

For a smaller lab, a compact furnace might be "easier" to integrate into the existing space, even if it requires running more frequent cycles.

Cycle Speed vs. Restoration Quality

Some furnaces offer "speed" cycles that can drastically shorten sintering time. While tempting, these accelerated cycles can sometimes compromise the translucency or strength of the final restoration.

An easy-to-use furnace should provide clear guidance on when to use these cycles, but the ultimate decision requires balancing speed with the demand for quality.

Upfront Cost vs. Long-Term Reliability

A lower-priced furnace might seem like an easy choice financially, but if it's built with inferior components, it will lead to operational difficulty.

Frequent breakdowns, inconsistent heating, and the need for constant recalibration create far more work and stress than a reliable, well-built machine. Investing in quality construction, like rigid ceramic fiberboard insulation, pays dividends in operational ease.

Making the Right Choice for Your Lab

Selecting the right furnace depends entirely on your lab's specific goals and workflow.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber capacity, robust automation, and proven long-term reliability to minimize downtime.

- If your primary focus is material versatility: Look for a furnace with a wide temperature range and the ability to easily create and store numerous custom firing programs.

- If your primary focus is minimizing errors and training: Choose a model with a highly intuitive touchscreen interface and a comprehensive library of pre-set, manufacturer-approved programs.

Ultimately, the easiest furnace to use is the one that empowers your team to produce exceptional restorations reliably and efficiently.

Summary Table:

| Feature | Benefit |

|---|---|

| Intuitive UI | Reduces learning curve and errors with clear displays and logical controls |

| Pre-set Programs | Ensures optimal results for common materials without manual setup |

| Precise Temperature Control | Maintains accuracy for reliable, high-quality restorations |

| Customizable Programs | Offers flexibility for new materials or specialized cases |

| Connectivity | Allows remote monitoring for improved workflow efficiency |

| Durable Heating Elements | Minimizes downtime with consistent performance over time |

Upgrade your dental lab with KINTEK's advanced sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met precisely. Contact us today to enhance efficiency, reduce errors, and boost profitability with our tailored furnace solutions!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations