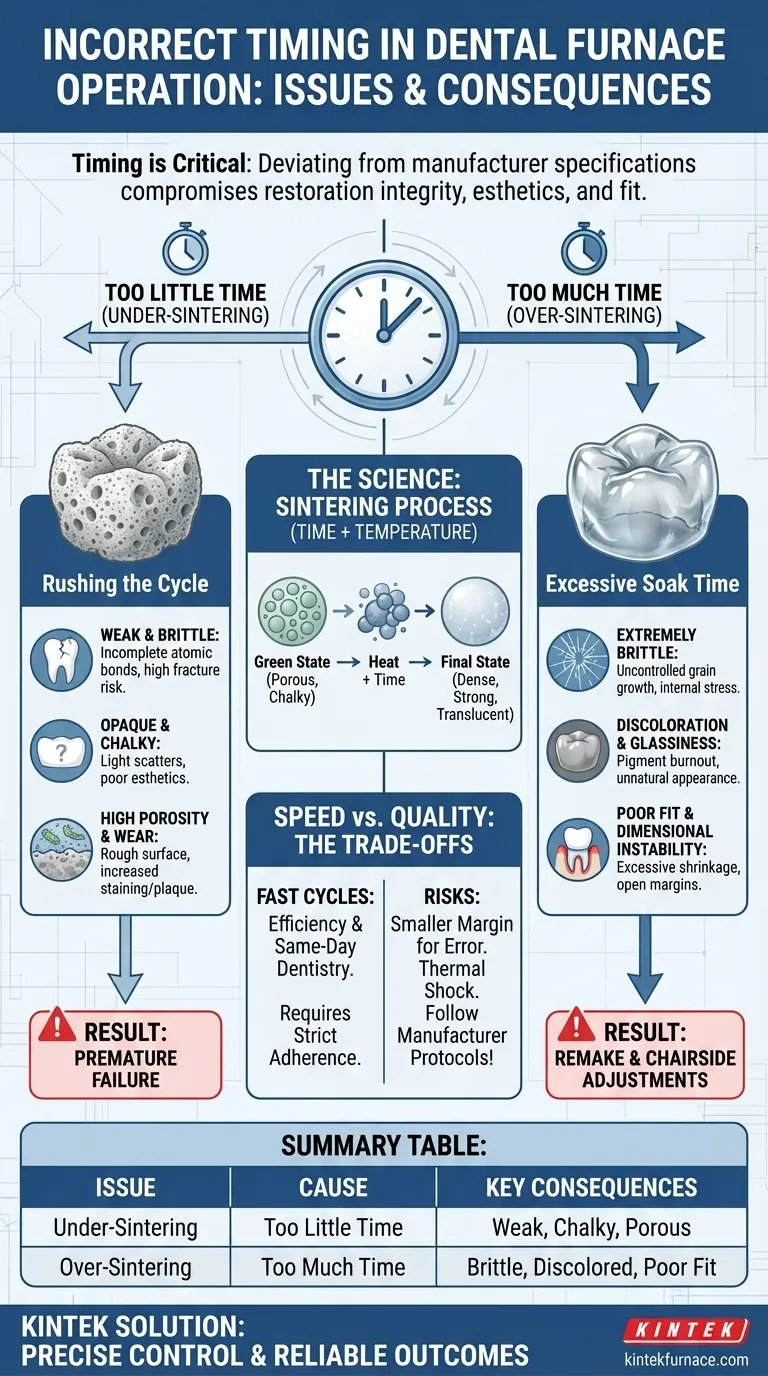

In dental prosthetics, timing is everything. Incorrect timing in a dental furnace is a primary cause of restoration failure, leading to two distinct outcomes. If the material is fired for too little time, it will be under-sintered, resulting in a weak and chalky restoration. If it is fired for too long, it becomes over-sintered, leading to discoloration, brittleness, and poor dimensional accuracy.

A furnace's timer is not merely a clock; it is a critical control governing the material science of the restoration. Deviating from the manufacturer's specified duration directly compromises the structural integrity, esthetics, and clinical fit, turning precise digital work into a costly failure.

The Science of Sintering: Time and Temperature in Tandem

To understand the problems, we must first understand the process. Sintering is not simply baking; it is a complex process of transforming a porous, chalk-like "green state" material into a dense, strong, and translucent ceramic.

What is Sintering?

Sintering uses heat to fuse ceramic particles together at a temperature below their melting point. Atoms diffuse across the boundaries of the particles, causing them to bond and grow, which eliminates the microscopic pores between them.

Why Time is a Critical Variable

Time is the catalyst that allows the heat to do its work. A specific duration is required for the atomic diffusion to complete, for crystals to grow to their optimal size, and for the material to achieve its target density and strength. Heat and time are an inseparable pair in any firing cycle.

The Consequences of Under-Sintering (Too Little Time)

Rushing the sintering cycle or setting the timer incorrectly is a common mistake that leads to a fundamentally incomplete restoration. The material never reaches its final, intended state.

Compromised Strength and Durability

The most significant issue with under-sintering is a dramatic reduction in flexural strength. The atomic bonds between particles have not fully formed, leaving a porous and weak internal structure. This restoration is highly susceptible to fracture under normal occlusal (biting) forces.

Poor Esthetics and Opacity

A properly sintered restoration is translucent because light can pass through its dense, crystalline structure. An under-sintered restoration is full of microscopic pores that scatter light, resulting in a flat, opaque, and chalky appearance. It will fail to blend with natural dentition.

Increased Porosity and Wear

The porous surface of an under-sintered crown is rougher on a microscopic level. This can accelerate the wear of opposing natural teeth and makes the restoration more prone to staining and plaque accumulation over time.

The Consequences of Over-Sintering (Too Much Time)

Allowing a restoration to "soak" at peak temperature for too long is just as destructive as cutting the time short. It pushes the material past its optimal state.

Uncontrolled Grain Growth and Brittleness

Excessive time at high temperature causes the crystalline grains within the ceramic to grow too large. While this may create a very hard material, it also introduces internal stresses and makes it extremely brittle. Like glass, it may resist scratching but will be prone to catastrophic fracture.

Esthetic Failures: Discoloration and Translucency Issues

Over-sintering can "burn out" the delicate pigments used to shade the restoration, causing it to appear gray, washed-out, or otherwise discolored. It can also lead to excessive "glassiness," an unnatural, high-value appearance that does not match the patient's existing teeth.

Dimensional Instability and Poor Fit

This is a critical clinical problem. Sintering involves predictable material shrinkage. Over-sintering can cause excessive or non-uniform shrinkage, resulting in a restoration that does not fit the preparation. This leads to open margins, poor seating, and excessive chairside adjustment time, often forcing a complete remake of the case.

Understanding the Trade-offs: Speed vs. Quality

Modern furnaces and materials often promote "speed" or "fast" sintering cycles. While valuable, these cycles demand a higher level of process control and carry inherent risks if not followed perfectly.

The Lure of Fast-Sintering Cycles

Fast cycles dramatically improve lab efficiency and enable same-day dentistry, which is a powerful advantage. They are designed to ramp up to and down from peak temperature very quickly.

The Risks of Rushing the Process

These accelerated cycles operate with a much smaller margin for error. A minor deviation in timing or temperature—which might be forgiven in a longer, traditional cycle—can have a magnified negative effect. Rapid heating can also introduce thermal shock, creating micro-fractures before the restoration is ever delivered.

The Need for Strict Adherence

Fast-sintering cycles are only reliable when you use the exact material, furnace, and program parameters validated by the manufacturers. Any deviation from this prescribed combination is an uncontrolled experiment that risks the quality of the final product.

Making the Right Choice for Your Goal

Your approach to furnace timing should be dictated by your clinical or business objective for each specific case. There is no single "best" cycle; there is only the correct cycle for the material you are using.

- If your primary focus is maximum esthetics and strength: Always adhere to the material manufacturer's recommended standard sintering cycles, as these are designed for optimal physical and optical properties.

- If your primary focus is lab efficiency and turnaround time: Only use accelerated "speed" cycles that are explicitly validated by both the material and furnace manufacturers for your specific combination.

- If you are experiencing inconsistent results: Immediately calibrate your furnace's temperature and timing controls and revert to using the most conservative, manufacturer-recommended standard cycle until the issue is resolved.

Ultimately, treating the furnace and material manuals as a non-negotiable protocol is the most reliable path to predictable, high-quality results.

Summary Table:

| Issue Type | Causes | Key Consequences |

|---|---|---|

| Under-Sintering | Too little firing time | Weak strength, chalky appearance, high porosity |

| Over-Sintering | Too much firing time | Brittleness, discoloration, poor dimensional fit |

Struggling with inconsistent dental restoration results? KINTEK offers advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored for dental labs. With our deep customization capabilities, we ensure precise temperature and timing control to prevent sintering errors and enhance restoration quality. Contact us today to discuss how our expertise can optimize your furnace operations and deliver reliable, high-quality outcomes for your patients!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab