At its core, vacuum hardening is a high-purity heat treatment process used to increase the hardness and strength of metal parts. It involves heating the metal in a sealed, air-free chamber and then rapidly cooling it. The defining feature—the vacuum—prevents harmful reactions like oxidation from occurring, resulting in a component that is not only hard but also has a clean, bright surface and minimal distortion.

The true value of vacuum hardening isn't just about making metal harder; it's about achieving that hardness while perfectly preserving the component's surface finish and dimensional accuracy, eliminating the need for costly and damaging post-treatment cleaning.

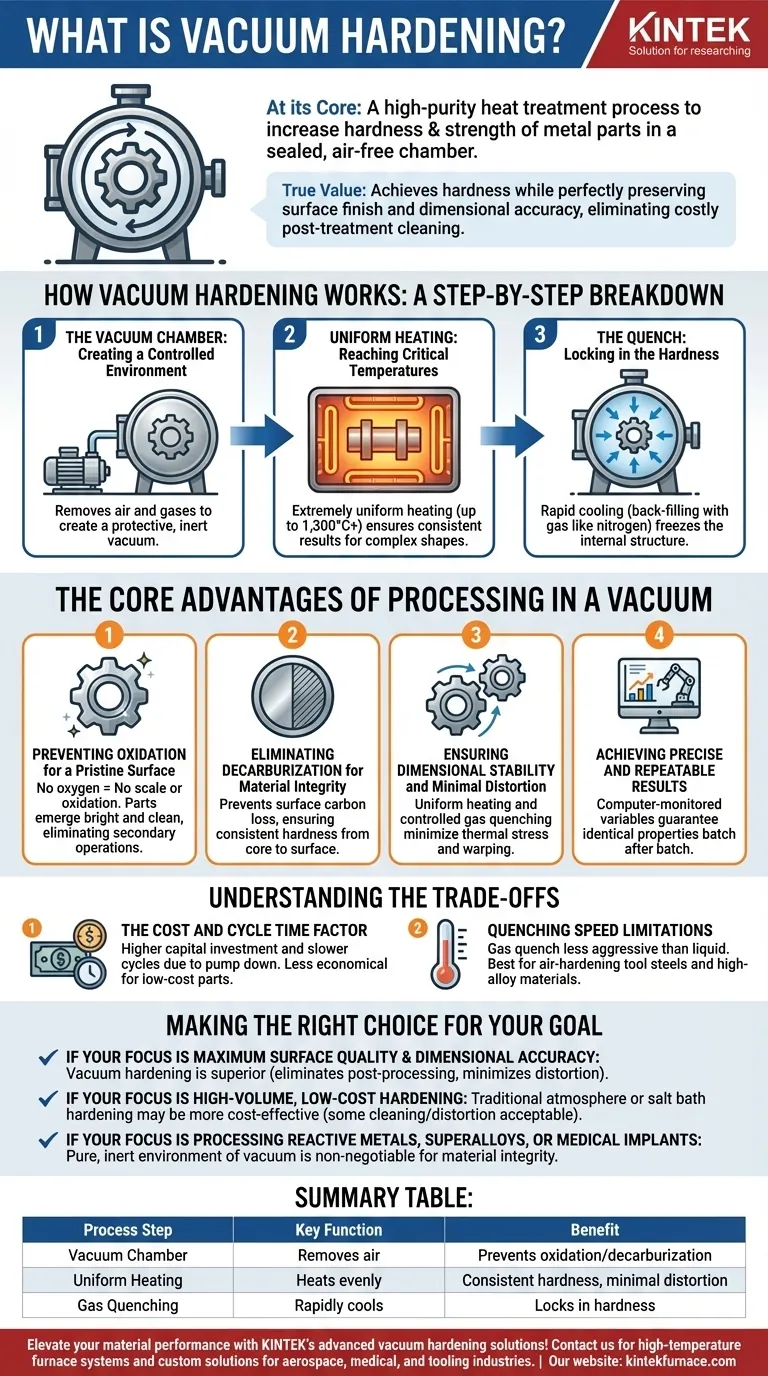

How Vacuum Hardening Works: A Step-by-Step Breakdown

The process is a precisely controlled sequence designed to modify the metal's internal crystal structure. It is managed by computers to ensure perfect repeatability from one batch to the next.

The Vacuum Chamber: Creating a Controlled Environment

First, components are loaded into a sealed furnace. Pumps then remove the air and other gases, creating a vacuum. This protective, inert environment is the key to preventing unwanted chemical reactions with the hot metal surface.

Uniform Heating: Reaching Critical Temperatures

Inside the vacuum, heating elements made of materials like molybdenum or tungsten raise the temperature, which can exceed 1,300°C (2,372°F). This heating is extremely uniform, ensuring the entire component—including complex shapes—reaches the target temperature consistently.

The Quench: Locking in the Hardness

After being held at temperature, the parts are rapidly cooled, or quenched. This is typically done by back-filling the chamber with a high-pressure inert gas like nitrogen or argon. This rapid cooling freezes the metal's internal structure in its hardened state.

The Core Advantages of Processing in a Vacuum

The decision to use a vacuum is deliberate, offering distinct metallurgical benefits that traditional atmosphere furnaces cannot match.

Preventing Oxidation for a Pristine Surface

With no oxygen present, the metal cannot oxidize or form scale. Parts emerge from the furnace with a bright, clean surface, identical to how they went in. This eliminates the need for abrasive secondary operations like sandblasting or grinding.

Eliminating Decarburization for Material Integrity

Decarburization is the loss of carbon from the surface of steel at high temperatures, which makes the surface softer and more prone to fatigue. The vacuum environment completely prevents this, ensuring the hardness is consistent from the core to the absolute surface of the part.

Ensuring Dimensional Stability and Minimal Distortion

The combination of uniform heating and controlled gas quenching minimizes the thermal stress put on a component. This results in exceptional dimensional stability and drastically reduces the warping or distortion common in liquid quenching (oil or water).

Achieving Precise and Repeatable Results

Vacuum furnaces offer unparalleled process control. Every variable—temperature, time, vacuum level, and quench pressure—is computer-monitored and executed. This guarantees that a part processed today will have the exact same properties as a part processed a year from now.

Understanding the Trade-offs

While powerful, vacuum hardening is not a universal solution. Its precision and quality come with specific considerations.

The Cost and Cycle Time Factor

Vacuum furnaces represent a significant capital investment, and the process itself can be slower than conventional methods due to the time required to pump down the chamber. This makes it less economical for simple, low-cost parts where surface finish is not critical.

Quenching Speed Limitations

While gas quenching is highly controlled, it is less aggressive than a liquid quench. For some low-alloy steels with poor hardenability, a gas quench may not be fast enough to achieve maximum hardness throughout the part's cross-section. It is best suited for air-hardening tool steels and higher-alloy materials.

Making the Right Choice for Your Goal

Selecting the right hardening process depends entirely on the component's final application and performance requirements.

- If your primary focus is maximum surface quality and dimensional accuracy: Vacuum hardening is the superior choice, as it eliminates post-processing and minimizes distortion for complex or tight-tolerance parts.

- If your primary focus is high-volume, low-cost hardening of simple parts: Traditional atmosphere or salt bath hardening may be a more cost-effective solution, provided some surface cleaning and distortion are acceptable.

- If your primary focus is processing reactive metals, superalloys, or medical implants: The pure, inert environment of a vacuum furnace is non-negotiable to prevent contamination and achieve the required material properties.

Ultimately, choosing vacuum hardening is an investment in precision, quality, and material integrity from the very beginning of your manufacturing process.

Summary Table:

| Process Step | Key Function | Benefit |

|---|---|---|

| Vacuum Chamber | Removes air to create inert environment | Prevents oxidation and decarburization |

| Uniform Heating | Heats metal evenly to critical temperatures | Ensures consistent hardness and minimal distortion |

| Gas Quenching | Rapidly cools with inert gas | Locks in hardness with controlled cooling |

Elevate your material performance with KINTEK's advanced vacuum hardening solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Vacuum & Atmosphere Furnaces, designed for precision and repeatability. Our strong deep customization capability ensures we meet your unique experimental needs, delivering clean, distortion-free results for industries such as aerospace, medical, and tooling. Contact us today to discuss how our tailored solutions can enhance your process efficiency and product quality!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance