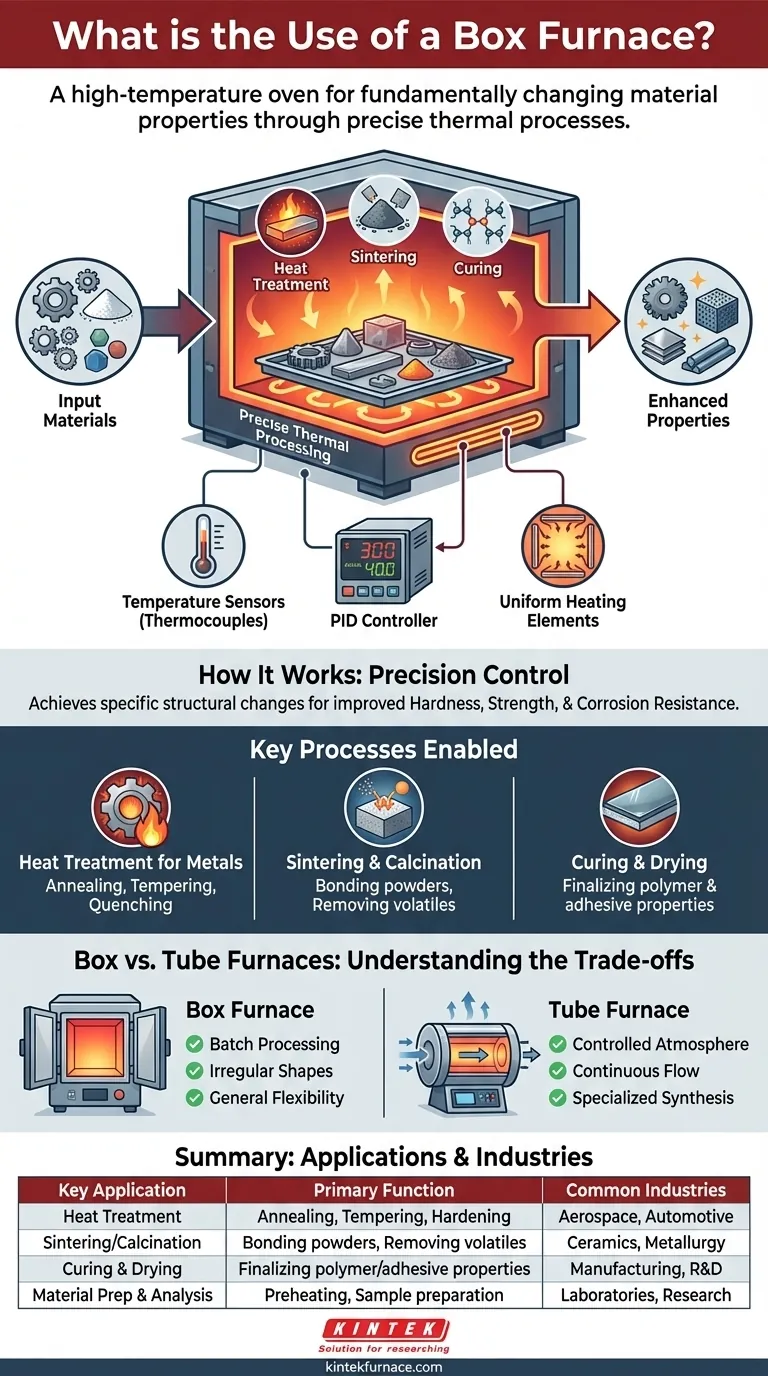

In short, a box furnace is a high-temperature oven used to fundamentally change the properties of materials. Its primary function is to execute precise thermal processes like heat treatment, sintering, and curing for components used in industries ranging from aerospace and automotive to scientific research.

The true purpose of a box furnace goes beyond simple heating. It is a tool for precisely controlling a material's thermal environment to intentionally alter its internal structure, thereby achieving specific, enhanced properties like increased hardness, strength, or chemical stability.

How a Box Furnace Transforms Materials

A box furnace isn't just about making things hot; it's about making them better. The controlled application of heat is a powerful method for manipulating a material at a microscopic level to achieve a desired macroscopic result.

Achieving Specific Material Properties

The core goal of most box furnace processes is to enhance a material's characteristics. By carefully managing temperature and time, you can induce specific structural changes.

This results in improved hardness, strength, and corrosion resistance, making a component suitable for its demanding final application.

The Critical Role of Temperature Control

This level of precision is only possible with sophisticated control systems. Modern box furnaces use an integrated system to ensure accuracy and repeatability.

This typically includes temperature sensors (like thermocouples), PID controllers that intelligently manage power output to prevent overshooting, and user interfaces that allow for complex heating profiles.

Preparing Materials for Analysis and Processing

Beyond enhancement, box furnaces are used to prepare materials. This can involve simple preheating to ready a part for a subsequent manufacturing step.

In laboratory settings, they are essential for element analysis or high-temperature dissolution, where a sample must be brought to a specific state before it can be accurately measured.

Key Processes Enabled by a Box Furnace

The versatility of a box furnace comes from the wide range of thermal processes it can perform. These applications can be grouped by their primary objective.

Heat Treatment for Metals

This is one of the most common uses, especially for small steel parts.

- Annealing: Heating and slowly cooling a metal to soften it and improve its ductility.

- Tempering: Heating a previously hardened metal to a lower temperature to reduce brittleness and increase toughness.

- Quenching: Rapidly cooling a metal to lock in a specific crystalline structure, often to increase hardness.

Sintering and Calcination

These processes are vital for creating solid materials from powders, particularly in ceramics and metallurgy.

- Sintering: Heating powdered material below its melting point until its particles bond together, forming a solid or porous mass.

- Calcination: Heating a solid material to drive off volatile substances, such as removing water or carbon dioxide.

Curing and Drying

Many industrial processes rely on curing to finalize a material's properties. A box furnace provides the stable, uniform heat needed for curing polymers, adhesives, and coatings.

Understanding the Trade-offs: Box vs. Tube Furnaces

While versatile, a box furnace is not the only option. Understanding its design helps clarify when it is the right choice over a more specialized tool like a tube furnace.

The Advantage of Capacity and Accessibility

The primary advantage of a box furnace is its chamber design. The front-loading "box" shape is ideal for batch processing multiple parts at once or handling components with irregular shapes and sizes. Its design prioritizes general-purpose flexibility and ease of use.

When a Tube Furnace Is a Better Fit

A tube furnace excels in applications requiring a highly controlled atmosphere or a continuous flow. Its tubular chamber is perfect for processes involving reactive gases, performing chemical vapor deposition, or for experiments where samples must be dropped in from the top.

Making the Right Choice for Your Application

Selecting the correct furnace requires matching the tool to the specific thermal process and material requirements.

- If your primary focus is batch processing various parts for heat treatment: The accessible chamber and versatile control of a box furnace make it the ideal choice.

- If your primary focus is material research and property testing: A box furnace provides the precise, repeatable heating needed for analyzing and developing new materials.

- If your primary focus is a continuous process or requires a controlled gas atmosphere: You should evaluate a tube furnace, as its design is better suited for specialized syntheses and gas-based reactions.

Ultimately, selecting the right furnace depends on a clear understanding of your material, process, and desired outcome.

Summary Table:

| Key Application | Primary Function | Common Industries |

|---|---|---|

| Heat Treatment | Annealing, Tempering, Hardening | Aerospace, Automotive |

| Sintering/Calcination | Bonding powders, Removing volatiles | Ceramics, Metallurgy |

| Curing & Drying | Finalizing polymer/adhesive properties | Manufacturing, R&D |

| Material Prep & Analysis | Preheating, Sample preparation | Laboratories, Research |

Ready to Enhance Your Material Properties with Precision?

At KINTEK, we understand that achieving the perfect hardness, strength, or thermal stability requires more than just heat—it demands a furnace built for precision and reliability. Our advanced box furnaces are engineered with sophisticated PID control and uniform heating chambers to deliver the exact thermal environment your materials need.

Leveraging our exceptional in-house R&D and manufacturing, we offer deep customization to tailor a high-temperature furnace solution—whether it's a Muffle, Tube, Vacuum, or Atmosphere Furnace—to your unique experimental and production requirements.

Let's discuss how a KINTEK box furnace can transform your processes. Contact our experts today for a solution that fits your specific application.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing