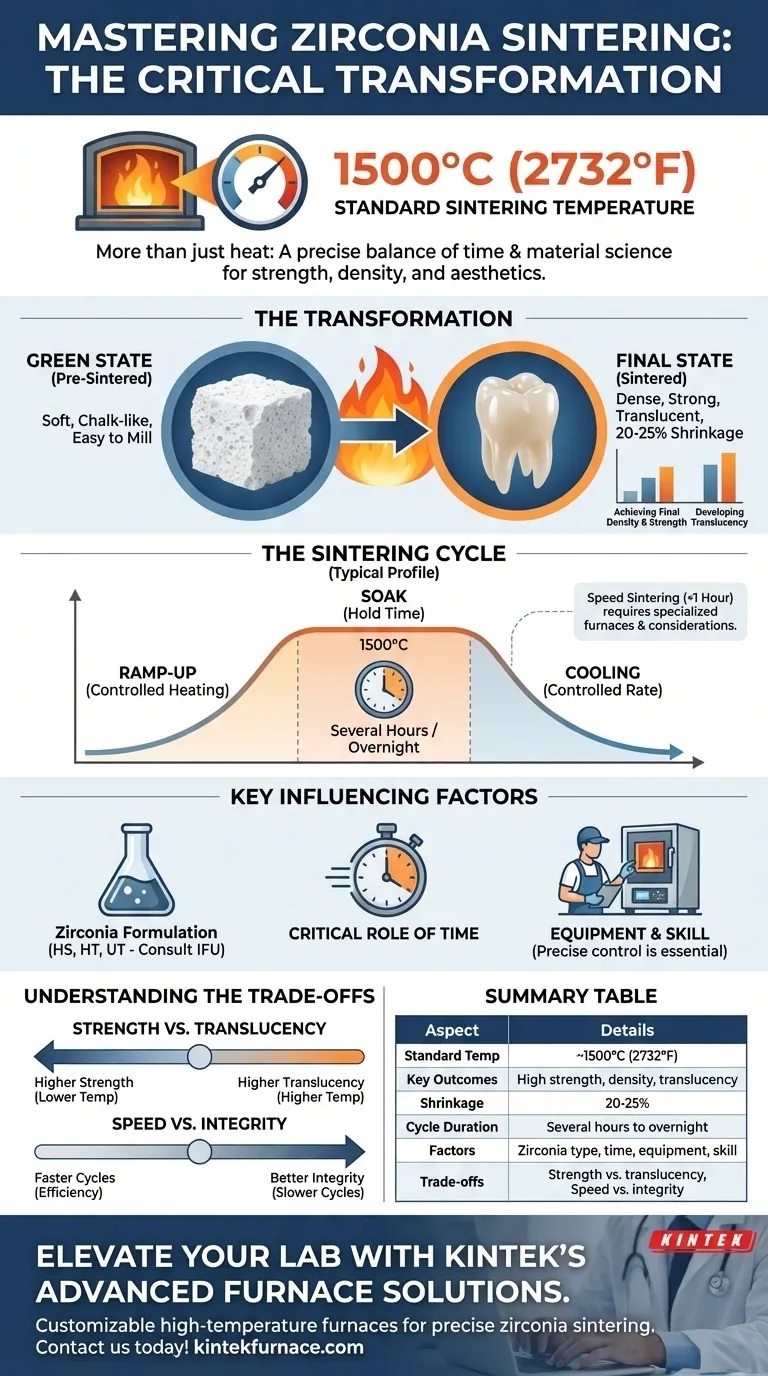

In practice, the standard sintering temperature for most dental zirconia restorations is approximately 1500° Celsius (2732° Fahrenheit). This high-temperature process is not merely about heating; it is a critical transformation phase that gives the final restoration its necessary strength, density, and aesthetic translucency. The specific temperature and duration, however, are part of a carefully controlled cycle that dictates the final outcome.

Sintering is more than hitting a target temperature. It is a precise process of balancing heat, time, and material science to transform a fragile, chalk-like block into a dense, high-performance ceramic restoration with predictable physical and aesthetic properties.

The Role of Sintering in Zirconia Transformation

Sintering is the fundamental process that converts a porous, pre-sintered zirconia block into its final, dense ceramic form. Understanding this transformation is key to controlling the quality of the final restoration.

From Pre-Sintered to Final State

A zirconia restoration begins in a "green state," a soft, chalk-like consistency that is easy to mill. During sintering, the extreme heat causes the individual zirconia particles to fuse and compact, eliminating the pores between them.

This process results in a predictable volumetric shrinkage of about 20-25%, transforming the oversized, fragile milled crown into its precise final dimensions and robust structure.

Achieving Final Density and Strength

The primary goal of reaching temperatures around 1500°C is to achieve maximum densification. This process eliminates voids within the material, creating a monolithic structure that is exceptionally strong and resistant to fracture. Incomplete sintering results in a weaker, more porous restoration that is clinically unacceptable.

Developing Translucency

Aesthetics are just as critical as strength. As the material densifies and porosity is removed, light is able to pass through the ceramic with less scattering. Higher sintering temperatures generally lead to greater translucency, which is crucial for creating natural-looking anterior restorations.

Key Factors Influencing the Sintering Cycle

While 1500°C is a reliable benchmark, it is not a universal constant. The ideal sintering cycle is influenced by several variables that a technician must manage.

Zirconia Formulation

Different types of zirconia are engineered for different purposes. High-strength (HS) zirconia, often used for posterior bridges, may have a different recommended cycle than a high-translucency (HT) or ultra-translucency (UT) material intended for veneers or anterior crowns.

Always consult the manufacturer's instructions for use (IFU) for the specific material you are working with.

The Critical Role of Time

Sintering is not instantaneous. A typical cycle can last for several hours or even run overnight. This includes a controlled ramp-up rate, a "hold" or "soak" time at the peak temperature, and a controlled cooling rate.

Shorter "speed sintering" cycles exist, but they require specialized furnaces and carry their own set of considerations.

Equipment and Technician Skill

The quality of the final restoration is directly dependent on the tools and the operator. A modern, well-calibrated sintering furnace is essential for maintaining precise and consistent temperatures.

Furthermore, an experienced technician understands how to interpret manufacturer recommendations and adjust parameters to achieve consistently excellent results, turning the process from a simple task into a technical art.

Understanding the Trade-offs

Achieving the perfect restoration involves balancing competing properties. Optimizing for one characteristic can sometimes compromise another.

Strength vs. Translucency

Generally, sintering at the higher end of the recommended temperature range can increase translucency. However, pushing the temperature too high for too long can sometimes lead to excessive grain growth, which may slightly reduce the material's flexural strength. This trade-off is most relevant when choosing between maximum aesthetics and maximum durability.

Speed vs. Integrity

Speed sintering cycles, which can finish in under an hour, offer incredible efficiency. However, rapid heating and cooling can introduce thermal stress into the ceramic. This may increase the risk of micro-fractures or reduce the long-term stability of the restoration if not performed with a compatible material and a furnace specifically designed for such cycles.

Making the Right Choice for Your Goal

The ideal sintering protocol depends entirely on the clinical objective and the material selected.

- If your primary focus is maximum strength: Strictly adhere to the manufacturer's standard cycle for a high-strength zirconia, ensuring a full hold time to achieve complete densification.

- If your primary focus is optimal aesthetics: Select a high-translucency zirconia and follow its specific sintering profile, which may prioritize a higher peak temperature to enhance light transmission.

- If your primary focus is lab efficiency: Use a speed-sintering-compatible zirconia and a validated furnace, but always perform quality control to ensure the final product's integrity is not compromised.

Ultimately, mastering the sintering process transforms a simple temperature value into a predictable and high-quality clinical outcome.

Summary Table:

| Aspect | Details |

|---|---|

| Standard Sintering Temperature | ~1500°C (2732°F) |

| Key Outcomes | High strength, density, translucency |

| Volumetric Shrinkage | 20-25% |

| Typical Cycle Duration | Several hours to overnight |

| Influencing Factors | Zirconia type, time, equipment, technician skill |

| Trade-offs | Strength vs. translucency, speed vs. integrity |

Elevate your dental lab's performance with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique sintering needs for zirconia restorations. Achieve precise temperature control, consistent results, and enhanced efficiency—contact us today to discuss how our solutions can benefit your laboratory!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations