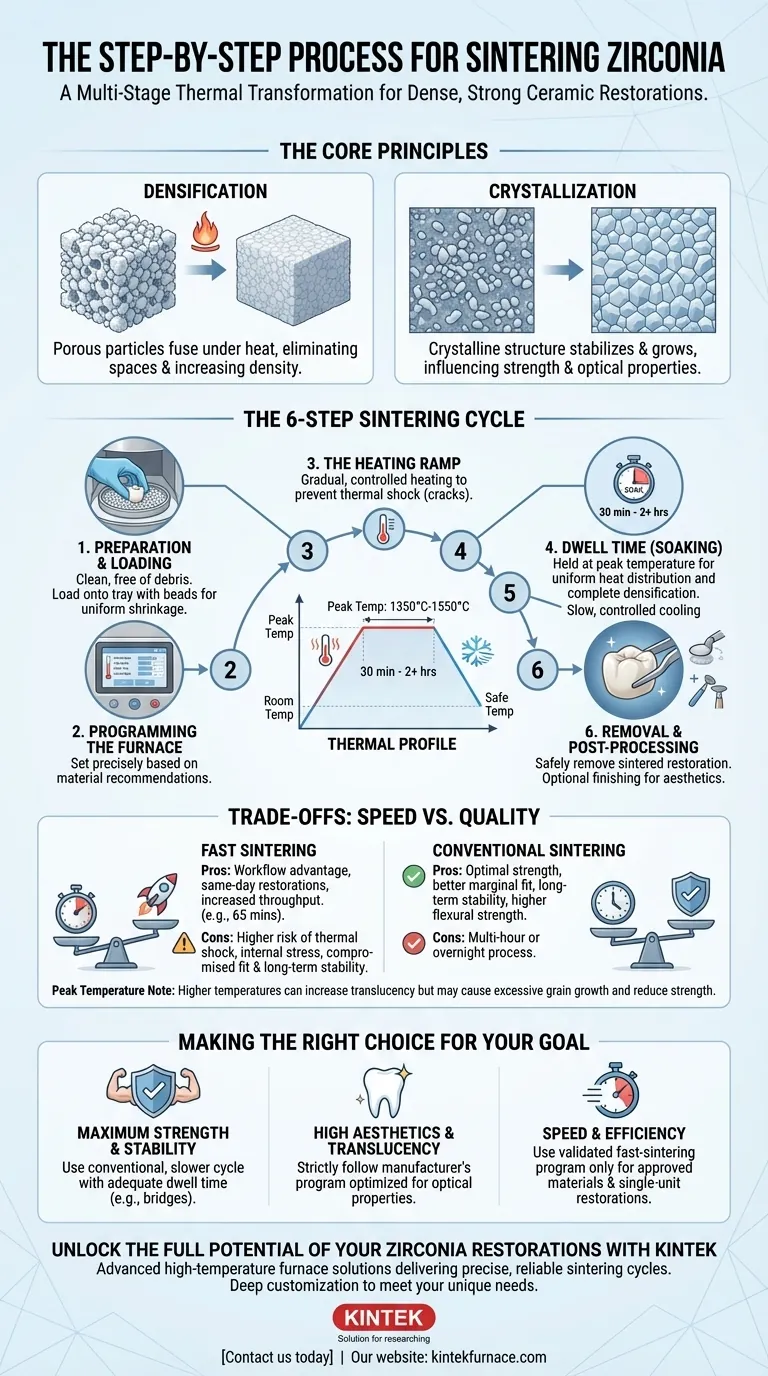

Sintering zirconia is a multi-stage thermal process that transforms a soft, chalk-like pre-sintered material into a dense, strong, and final ceramic restoration. The process involves a precisely controlled heating ramp up to a peak temperature between 1350°C and 1550°C, holding it for a specific duration (soaking), and then carefully cooling it back to room temperature. This controlled cycle is what gives the final zirconia its required strength, durability, and aesthetic properties.

Sintering is not merely a heating process; it is a controlled material transformation. The success of a zirconia restoration depends entirely on the precise management of temperature and time throughout the cycle to achieve full densification without introducing internal stress or defects.

The Core Principles of Zirconia Sintering

Before examining the steps, it is crucial to understand what is happening at a microscopic level. The initial zirconia block is porous. Sintering eliminates these pores.

What is Densification?

Densification is the process where the individual zirconia particles fuse together under high heat. This fusion eliminates the spaces between particles, causing the material to shrink significantly and increase in density.

The Role of Crystallization

As the material densifies, its crystalline structure also stabilizes and grows. The final size and arrangement of these crystals directly influence the material's mechanical strength and its optical properties, such as translucency.

The Step-by-Step Sintering Cycle

A successful sintering outcome relies on a programmable furnace that executes a precise thermal profile. While specific times and temperatures vary by zirconia manufacturer, the fundamental stages remain constant.

Step 1: Preparation and Loading

The first step involves preparing the milled zirconia restoration. It should be clean and free of dust or debris before being carefully placed into the sintering furnace chamber, often on a tray with sintering beads to allow for uniform shrinkage.

Step 2: Programming the Furnace

Using the furnace's control interface (often a touch screen), you set the parameters for the sintering cycle. This includes the heating rate, the peak temperature, the dwell (or "soak") time, and the cooling rate. These settings must match the recommendations for the specific type of zirconia being used.

Step 3: The Heating Ramp

The furnace begins to heat up gradually. This controlled ramp is critical to prevent thermal shock, where a sudden temperature change can cause cracks in the material. Some programs include a pre-drying stage at a lower temperature to gently evaporate any residual moisture.

Step 4: Dwell Time (Soaking)

Once the furnace reaches the target temperature (typically 1350°C to 1550°C), it holds this temperature for a set period, known as the dwell time or soaking phase. This typically lasts from 30 minutes to over two hours and ensures heat is distributed uniformly throughout the restoration, allowing for complete and even densification.

Step 5: Controlled Cooling

Just as important as the heating ramp, the cooling phase must be slow and controlled. Rapid cooling can introduce internal stresses, leading to warping or fractures. The furnace slowly lowers the temperature to a safe level before the cycle is complete.

Step 6: Removal and Post-Processing

After the furnace has cooled sufficiently, the fully sintered, dense, and strong zirconia restoration can be safely removed. Optional post-processing steps may follow, such as minor adjustments, staining and glazing, or polishing to achieve the final desired aesthetic.

Understanding the Trade-offs: Speed vs. Quality

Modern furnaces offer "fast sintering" cycles, creating a critical decision point for any lab or clinic. Understanding the compromises is essential.

The Allure of Fast Sintering

Fast-sintering programs can reduce a multi-hour or overnight process to as little as 65 minutes. This offers a significant workflow advantage, enabling same-day restorations and increasing throughput.

The Risks of Rushing the Process

Rapid heating and cooling rates inherent in fast cycles can increase the risk of thermal shock and internal stress. This may compromise the marginal fit, long-term stability, or even the flexural strength of the final restoration compared to one made with a slower, conventional cycle.

The Impact of Sintering Temperature

The peak temperature affects the final properties. While a higher temperature can sometimes increase translucency in certain zirconia formulations, it can also lead to excessive grain growth, which may reduce the material's overall strength and fracture toughness. Always adhere to the manufacturer's validated temperature range.

Making the Right Choice for Your Goal

The ideal sintering cycle is not one-size-fits-all; it depends on the material you are using and your primary objective for the final restoration.

- If your primary focus is maximum strength and stability: Opt for a conventional, slower sintering cycle with adequate dwell time, especially for multi-unit bridges or cases requiring maximum durability.

- If your primary focus is high aesthetics and translucency: Strictly follow the manufacturer's specific program for their aesthetic zirconia, as these cycles are precisely engineered to optimize optical properties.

- If your primary focus is speed and efficiency: Use a validated fast-sintering program only with zirconia materials explicitly approved for such cycles and for single-unit restorations where the clinical demands allow for it.

Ultimately, mastering the sintering process is about faithfully executing a validated thermal protocol to unlock the full potential of the material.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Preparation and Loading | Clean and place zirconia in furnace for uniform shrinkage |

| 2 | Programming the Furnace | Set heating rate, peak temperature, dwell time, and cooling rate |

| 3 | Heating Ramp | Gradual temperature increase to prevent thermal shock |

| 4 | Dwell Time (Soaking) | Hold at 1350-1550°C for 30 min to 2+ hours for densification |

| 5 | Controlled Cooling | Slow temperature reduction to avoid internal stress and defects |

| 6 | Removal and Post-Processing | Extract restoration and perform optional finishing steps |

Unlock the Full Potential of Your Zirconia Restorations with KINTEK

Are you aiming for maximum strength, superior aesthetics, or faster turnaround times in your dental lab? KINTEK's advanced high-temperature furnace solutions—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—are engineered to deliver precise, reliable sintering cycles. With our strong deep customization capabilities, we tailor our equipment to meet your unique experimental and production needs, ensuring optimal densification and material properties every time.

Contact us today to discuss how our furnaces can enhance your sintering process and elevate your results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique