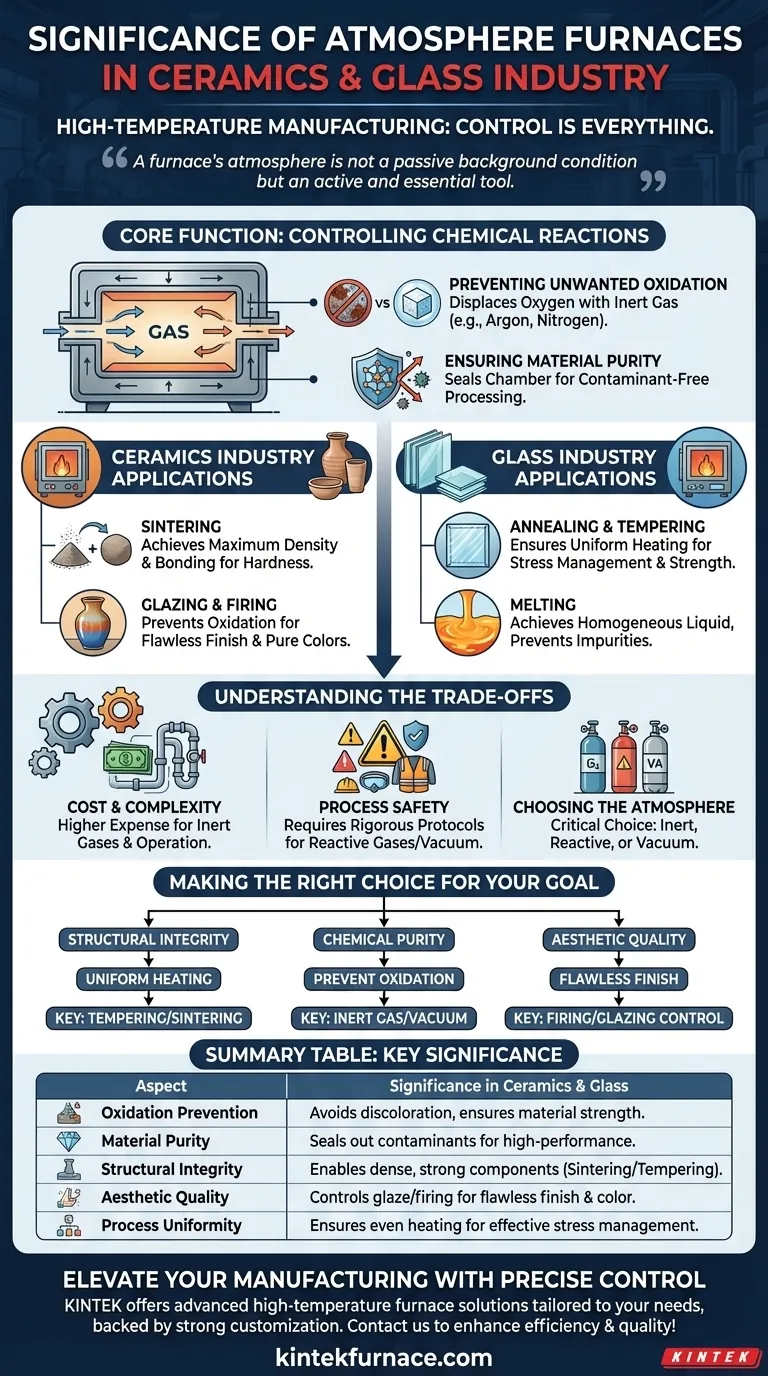

In high-temperature manufacturing, control is everything. Atmosphere furnaces are significant in the ceramics and glass industries because they provide precise control over the chemical environment during processing. This control is not a minor detail; it is the fundamental mechanism that prevents unwanted reactions like oxidation, ensures material purity, and ultimately dictates the final structural, mechanical, and aesthetic properties of the end product.

The crucial insight is that a furnace's atmosphere is not a passive background condition but an active and essential tool. By controlling this environment, manufacturers can move beyond simple heating and actively direct the chemical and physical transformations required to create high-performance ceramics and flawless glass.

The Core Function: Controlling Chemical Reactions

The primary value of an atmosphere furnace is its ability to create a tightly controlled chemical environment. This prevents the ambient air, primarily nitrogen and oxygen, from interfering with the material at high temperatures.

Preventing Unwanted Oxidation

At elevated temperatures, materials are highly reactive with oxygen. This oxidation can cause discoloration, surface defects, and a significant reduction in the material's strength and performance.

A controlled atmosphere, typically using an inert gas like argon or nitrogen, displaces the oxygen and prevents these destructive reactions from occurring.

Ensuring Material Purity

For advanced applications, especially in electronics and aerospace, even trace amounts of contamination can be catastrophic.

Atmosphere furnaces seal the processing chamber from outside contaminants, ensuring the chemical composition of the ceramic or glass remains exactly as intended throughout the heating cycle.

Applications in the Ceramics Industry

In ceramics manufacturing, controlling the furnace atmosphere is essential for transforming powders into dense, robust components.

Sintering: Achieving Maximum Density

Sintering is the process of heating ceramic powders to just below their melting point, causing the particles to bond together. This process is what gives ceramics their hardness and wear resistance.

An inert atmosphere ensures that no unwanted chemical reactions interfere with this bonding, allowing for the creation of components with maximum density and structural integrity.

Glazing and Firing

The final appearance and surface properties of many ceramics are determined during glazing and firing. The furnace atmosphere can directly impact the color and texture of the glaze.

By preventing oxidation, manufacturers can achieve pure colors and a flawless, unblemished finish on the final product.

Applications in the Glass Industry

For glass, heat treatment is about managing internal stresses and enhancing strength. The atmosphere plays a critical role in the uniformity and success of these processes.

Annealing and Tempering: Managing Internal Stress

Tempering involves heating glass to a high temperature and then cooling it rapidly to create compressive stress on the surface, dramatically increasing its strength. Annealing is a slower cooling process used to relieve internal stresses.

A controlled atmosphere ensures uniform heating across the entire glass surface. This prevents hot spots that could be caused by localized oxidation, ensuring the resulting stress profile is even and effective.

Melting

Even during the initial melting of raw materials, a controlled atmosphere can be beneficial. It can help achieve a more homogeneous liquid and prevent the incorporation of impurities that could affect the clarity and quality of the final glass product.

Understanding the Trade-offs

While essential, implementing atmosphere control introduces its own set of considerations.

Cost and Complexity

Operating an atmosphere furnace is more complex and costly than running a standard air-fired furnace. The continuous supply of high-purity inert gases like argon or nitrogen represents a significant operational expense.

Process Safety

Using different types of atmospheres, such as flammable reactive gases (e.g., hydrogen) or operating under a vacuum, requires rigorous safety protocols and specialized equipment to manage risks.

Choosing the Right Atmosphere

The choice of atmosphere is critical. Inert gas is for preventing reactions, reactive gas might be used to intentionally cause a specific chemical change (e.g., a reduction reaction), and a vacuum is the ultimate way to remove all atmospheric contaminants. Each choice has different equipment needs and costs.

Making the Right Choice for Your Goal

Your final objective determines which aspect of atmospheric control is most critical for your process.

- If your primary focus is structural integrity and strength: Your goal is uniform heating and cooling, making atmospheric control during tempering (for glass) or sintering (for ceramics) your key process.

- If your primary focus is chemical purity for high-performance applications: An inert gas or vacuum atmosphere is non-negotiable to prevent oxidation and contamination of sensitive materials like electronic-grade ceramics.

- If your primary focus is aesthetic quality: Controlling the atmosphere during firing and glazing is essential to prevent discoloration and surface defects, ensuring a perfect finish.

Ultimately, mastering the furnace atmosphere is what elevates high-temperature manufacturing from a craft into a precise and repeatable science.

Summary Table:

| Aspect | Significance in Ceramics & Glass |

|---|---|

| Oxidation Prevention | Uses inert gases to avoid discoloration and defects, ensuring material strength. |

| Material Purity | Seals out contaminants for high-performance applications in electronics and aerospace. |

| Structural Integrity | Enables uniform sintering and tempering for dense, strong components. |

| Aesthetic Quality | Controls glaze and firing processes for flawless finishes and colors. |

| Process Uniformity | Ensures even heating and cooling in annealing and tempering for stress management. |

Ready to elevate your ceramics or glass manufacturing with precise atmosphere control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance your process efficiency and product quality!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance