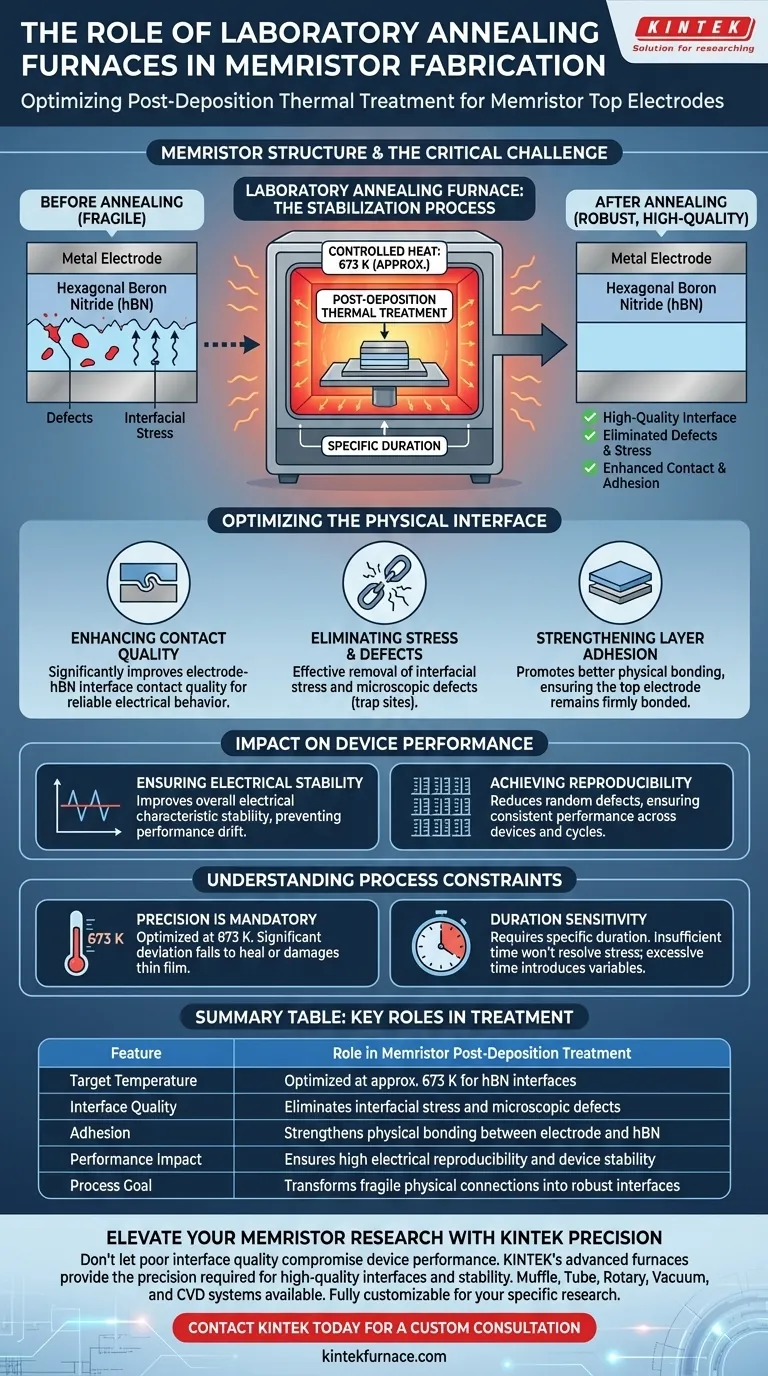

The laboratory annealing furnace serves a critical stabilization role in the fabrication of memristor top electrodes. Its primary function during post-deposition thermal treatment is to subject the device to controlled heat—specifically around 673 K—to fundamentally improve the interface between the metal electrode and the underlying hexagonal boron nitride (hBN) thin film.

The core value of this thermal treatment lies in interface engineering. By eliminating microscopic defects and stress, the annealing process transforms a fragile physical connection into a robust, high-quality interface, ensuring the device operates reliably.

Optimizing the Physical Interface

Enhancing Contact Quality

The critical boundary in this specific memristor structure is the point where the metal electrode meets the hexagonal boron nitride (hBN) thin film.

The annealing furnace heats this junction to significantly improve the interface contact quality. Without this step, the physical connection between the layers may remain poor, leading to erratic electrical behavior.

Eliminating Stress and Defects

Deposition processes often introduce mechanical tension and microscopic imperfections at the material boundary.

Thermal treatment at 673 K effectively eliminates this interfacial stress. Simultaneously, it works to remove defects that could act as trap sites or failure points within the device structure.

Strengthening Layer Adhesion

Beyond correcting defects, the furnace promotes better physical bonding between the materials.

This process enhances interlayer adhesion, ensuring the top electrode remains firmly bonded to the hBN layer during operation.

Impact on Device Performance

Ensuring Electrical Stability

The physical improvements to the interface have a direct correlation to electrical performance.

By stabilizing the contact point, the annealing process improves the overall stability of the memristor's electrical characteristics. This prevents performance drift over time.

Achieving Reproducibility

For a memristor to be viable, it must perform consistently across different cycles and devices.

The reduction of random defects and stress variables allows for high reproducibility. This ensures that the device switches states predictably every time it is used.

Understanding the Process Constraints

Precision is Mandatory

The effectiveness of this treatment relies on strict adherence to thermal parameters.

The process is optimized at a specific temperature, notably 673 K. Deviating significantly from this temperature may fail to induce the necessary interface healing or could damage the thin film.

Duration Sensitivity

Heat must be applied for a specific duration to achieve the desired results.

Insufficient time in the furnace will not fully resolve interfacial stress. Conversely, undefined or excessive exposure times introduce unnecessary variables into the fabrication process.

Making the Right Choice for Your Goal

To maximize the effectiveness of post-deposition thermal treatment, align your process controls with your specific reliability targets.

- If your primary focus is Device Longevity: Prioritize the elimination of interfacial stress to prevent physical delamination or degradation over time.

- If your primary focus is Manufacturing Consistency: Strict control over the 673 K temperature parameter is essential to ensure high reproducibility of electrical characteristics across all devices.

The laboratory annealing furnace is not just a heating element; it is a precision tool for locking in the structural integrity required for high-performance memristors.

Summary Table:

| Feature | Role in Memristor Post-Deposition Treatment |

|---|---|

| Target Temperature | Optimized at approximately 673 K for hBN interfaces |

| Interface Quality | Eliminates interfacial stress and microscopic defects |

| Adhesion | Strengthens physical bonding between electrode and hBN |

| Performance Impact | Ensures high electrical reproducibility and device stability |

| Process Goal | Transforms fragile physical connections into robust interfaces |

Elevate Your Memristor Research with KINTEK Precision

Don't let poor interface quality compromise your device performance. KINTEK’s advanced laboratory annealing furnaces provide the thermal precision required to achieve high-quality interfaces and reproducible electrical stability in memristor fabrication.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific research temperatures and atmospheres. Whether you are optimizing hBN thin films or developing next-generation high-temp lab applications, our solutions ensure your materials achieve peak structural integrity.

Ready to stabilize your thermal treatment process? Contact KINTEK today for a custom consultation!

Visual Guide

References

- Sibo Wang, Zhanguo Chen. Transfer-Free Analog and Digital Flexible Memristors Based on Boron Nitride Films. DOI: 10.3390/nano14040327

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment