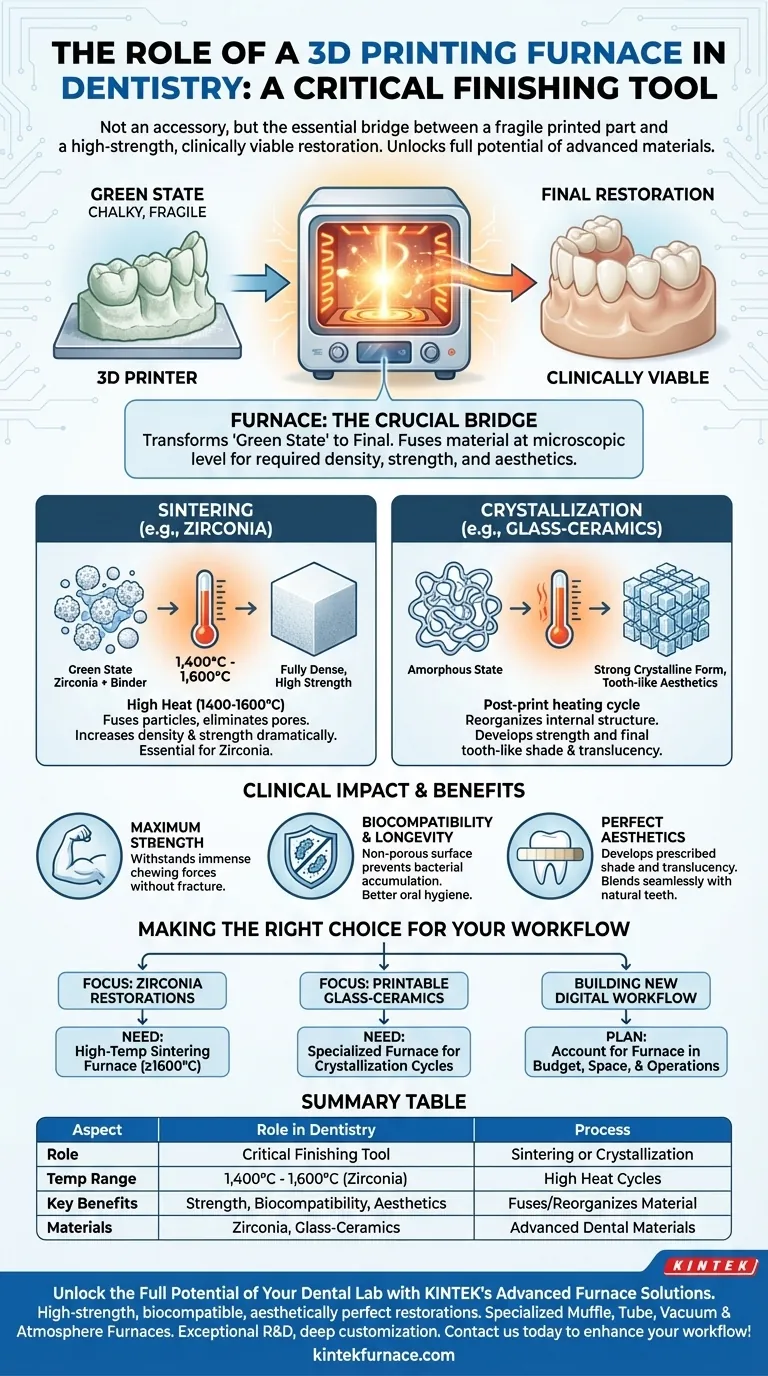

In dentistry, a 3D printing furnace is not an accessory but a critical finishing tool. It performs the essential post-processing step that transforms a fragile, newly printed part into a final, high-strength dental restoration. This process, most commonly known as sintering, fuses the printed material at a microscopic level to achieve the required density, strength, and aesthetic properties for clinical use in a patient's mouth.

The furnace is the crucial bridge between a 3D printed object and a clinically viable dental prosthesis. It is the step that unlocks the full mechanical and aesthetic potential of advanced materials like zirconia and glass-ceramics.

From "Green State" to Final Restoration

A part directly from a 3D printer is considered to be in its "green state." It has the correct shape but lacks the final density, hardness, and durability needed for a dental application. The furnace is where this transformation happens.

The Process of Sintering

Sintering is a thermal process that uses high heat—without melting—to fuse material particles together. This eliminates the microscopic pores between them, dramatically increasing the object's density and strength.

Think of it like turning a mound of loose sand into a solid piece of glass. The furnace provides the energy to bond the individual particles into a single, robust structure.

The Zirconia Workflow

Zirconia, a popular material for crowns and bridges due to its extreme strength, relies heavily on this process. Parts are typically printed with zirconia powder held together by a binder.

The furnace runs a precise, multi-stage cycle. First, it slowly burns out the binder at lower temperatures. Then, it ramps up to very high temperatures, often between 1,400°C and 1,600°C, to sinter the zirconia particles into a fully dense, monolithic state.

Crystallization for Glass-Ceramics

For other materials, like certain glass-ceramics, the furnace performs a slightly different function called crystallization.

These materials are printed in a weaker, amorphous state. A post-print heating cycle in the furnace reorganizes their internal structure into a stronger crystalline form, which also develops their final, tooth-like color and translucency.

The Impact on Clinical Outcomes

The furnace's function is not just a technical step; it directly influences the quality and safety of the final restoration that will be placed in a patient.

Achieving Maximum Strength

The primary goal of furnace post-processing is to achieve the material's specified flexural strength. A properly sintered crown or bridge can withstand the immense forces of chewing (mastication) without fracturing.

Ensuring Biocompatibility and Longevity

The sintering process creates a non-porous surface. This is critical for biocompatibility, as it reduces areas for bacteria and plaque to accumulate, contributing to better oral hygiene and the long-term health of surrounding tissues.

Perfecting Aesthetics

A restoration in its green state is often chalky, opaque, and not the correct color. The final heating cycle is what develops the material's prescribed shade and translucency, allowing it to blend seamlessly with the patient's natural teeth.

Making the Right Choice for Your Workflow

Understanding the furnace's role is key to planning a successful digital dentistry operation. It is as important as the 3D printer itself.

- If your primary focus is producing zirconia restorations: A high-temperature sintering furnace capable of reaching at least 1,600°C is an absolute requirement for your lab.

- If your primary focus is working with printable glass-ceramics: You will need a specialized furnace designed for the precise crystallization cycles required by those materials.

- If you are building a new digital workflow: Account for the furnace in your budget, space, and operational planning, as it is a core component for producing high-performance restorations.

Ultimately, the furnace is the final, transformative step that turns a digitally manufactured shape into a durable and aesthetic clinical solution.

Summary Table:

| Aspect | Role in Dentistry |

|---|---|

| Process | Sintering or crystallization to fuse materials |

| Temperature Range | 1,400°C to 1,600°C for zirconia sintering |

| Key Benefits | Increased strength, biocompatibility, and enhanced aesthetics |

| Materials Used | Zirconia, glass-ceramics |

Unlock the Full Potential of Your Dental Lab with KINTEK's Advanced Furnace Solutions

Are you aiming to produce high-strength, biocompatible, and aesthetically perfect dental restorations? KINTEK specializes in providing advanced high-temperature furnace solutions tailored for dentistry. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we can precisely meet your unique experimental and production needs, whether you're sintering zirconia or crystallizing glass-ceramics. Don't let post-processing hold you back—contact us today to discuss how our furnaces can enhance your workflow and deliver superior clinical outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time