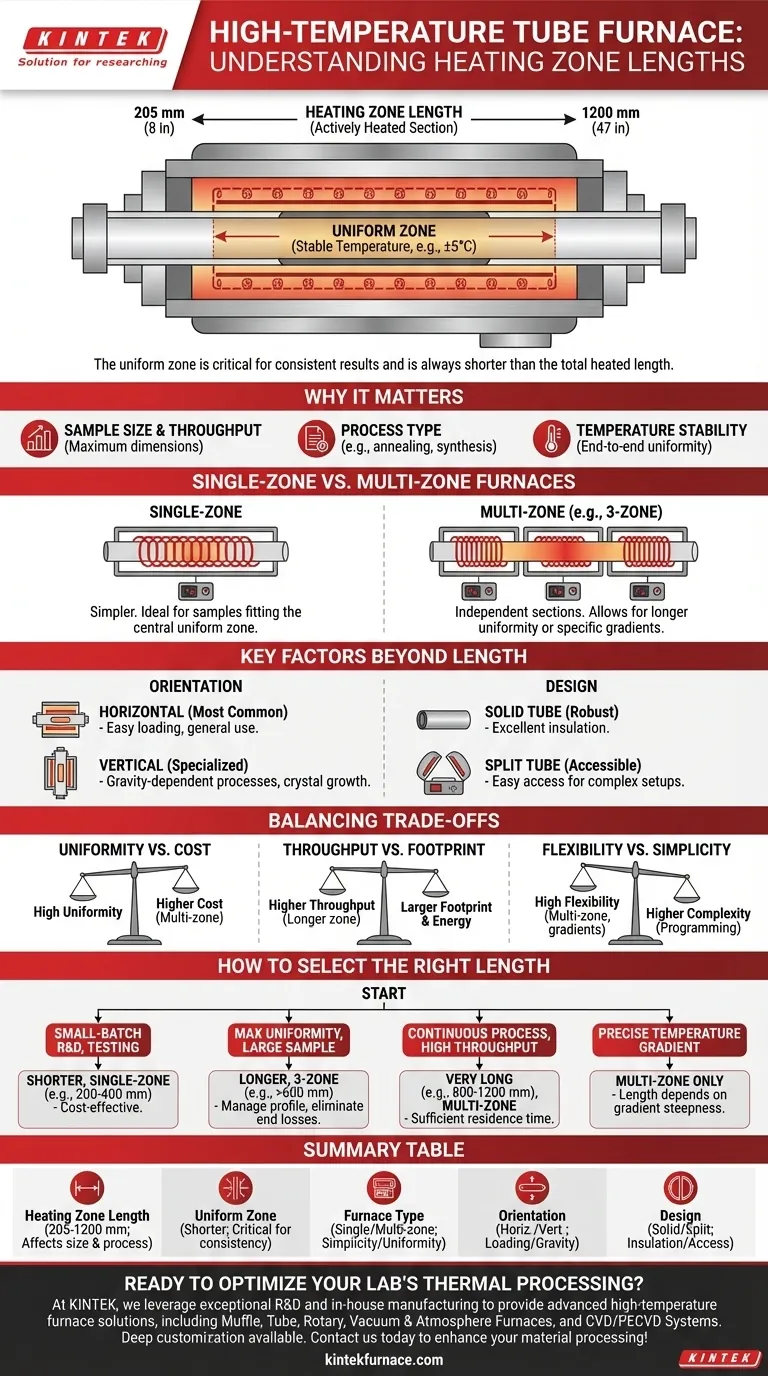

In practice, the heating zone length in a high-temperature tube furnace typically ranges from 205 mm (approximately 8 inches) to 1200 mm (approximately 47 inches). This length defines the section of the furnace tube that is actively heated by the surrounding electric coils. However, the effective working area is determined by more than just this single dimension.

The specified heating zone length is a starting point, but the true goal is to achieve a uniform temperature zone of a specific size. Understanding the difference between the total heated length and this uniform zone is critical for selecting the right furnace for your material processing needs.

Why Heating Zone Length is a Critical Parameter

The length of the heated zone is not an arbitrary specification; it directly dictates the furnace's capabilities. It's a primary factor in determining sample size, process type, and temperature stability.

Defining the "Uniform Zone"

The heating zone length refers to the physical length of the heating elements. However, heat naturally dissipates at the ends of the tube, creating a temperature drop.

The truly important dimension is the uniform zone. This is the central region within the heated zone where the temperature is stable and consistent within a specified tolerance (e.g., ±5°C).

As a rule, the uniform zone is always shorter than the total heating zone length. Longer heated zones generally produce a longer region of temperature uniformity.

Single-Zone vs. Multi-Zone Furnaces

Tube furnaces are available in single or multiple-zone configurations, which radically changes the function of the heated length.

A single-zone furnace has one continuous heating element and one controller. It is simpler and ideal for processing samples that fit comfortably within its central uniform zone.

A multi-zone furnace divides the total heated length into several independent sections (often three). Each zone has its own thermocouple and controller, allowing you to create a highly uniform temperature profile over a much longer length or to intentionally create a specific temperature gradient.

Key Factors Beyond Just Length

Choosing a furnace requires looking beyond a single number. The physical design and orientation are just as important as the heated length for a successful process.

Furnace Orientation: Horizontal vs. Vertical

Horizontal furnaces are the most common design. They are easy to load and well-suited for a wide range of applications like annealing, drying, or general chemical preparation.

Vertical furnaces, which stand upright, are used for specialized processes. They are ideal for applications where gravity is beneficial, such as crystal growth or when you need to prevent a sample from touching the tube walls.

Furnace Design: Split vs. Solid Tube

Solid tube furnaces are a single, fixed cylinder. They are robust and provide excellent temperature insulation.

Split tube furnaces are designed in two halves that can be opened like a clamshell. This provides much easier access to the work tube, which is invaluable for processes requiring complex setups or quick sample changes.

Understanding the Trade-offs

Selecting a furnace involves balancing competing priorities. The heated length is at the center of several key trade-offs.

Uniformity vs. Cost

Achieving a long, highly uniform temperature zone requires a more complex and expensive furnace. A three-zone furnace will provide superior uniformity over a 600 mm length compared to a single-zone furnace, but at a significantly higher cost.

Throughput vs. Footprint

Longer heating zones can accommodate larger samples or a continuous feed of material, increasing process throughput. The trade-off is the larger physical footprint and higher energy consumption.

Process Flexibility vs. Simplicity

A multi-zone furnace offers exceptional flexibility for creating custom temperature gradients for advanced materials synthesis. However, this comes with the added complexity of programming and managing multiple controllers. A short, single-zone furnace is far simpler to operate for basic heating tasks.

How to Select the Right Heated Length for Your Application

Base your decision on the specific requirements of your process, not just the raw specifications of the furnace.

- If your primary focus is small-batch R&D or sample testing: A shorter, single-zone furnace (e.g., 200-400 mm) is often the most cost-effective and practical choice.

- If your primary focus is maximum temperature uniformity for a large sample: A longer, three-zone furnace (e.g., 600 mm or more) is necessary to actively manage the temperature profile and eliminate end losses.

- If your primary focus is a continuous process or high throughput: A very long furnace (e.g., 800-1200 mm), likely with multiple zones, is required to provide sufficient residence time for the material.

- If your primary focus is creating a precise temperature gradient: A multi-zone furnace is your only option; the total length will depend on the steepness and length of the gradient you need to create.

Ultimately, choosing the right furnace is about matching its design and capabilities to the precise thermal environment your work demands.

Summary Table:

| Parameter | Typical Range | Key Insights |

|---|---|---|

| Heating Zone Length | 205 mm to 1200 mm | Defines the actively heated section; affects sample size and process type. |

| Uniform Zone | Shorter than heating zone | Central region with stable temperature (±5°C); critical for consistent results. |

| Furnace Type | Single-zone or Multi-zone | Single-zone for simplicity; multi-zone for uniformity and gradients. |

| Orientation | Horizontal or Vertical | Horizontal for easy loading; vertical for gravity-dependent processes. |

| Design | Solid or Split Tube | Solid for insulation; split for easy access and quick changes. |

Ready to optimize your lab's thermal processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're working with small-batch R&D, large samples, or continuous processes, we can help you achieve superior temperature control and efficiency. Contact us today to discuss how our furnaces can enhance your material processing!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents