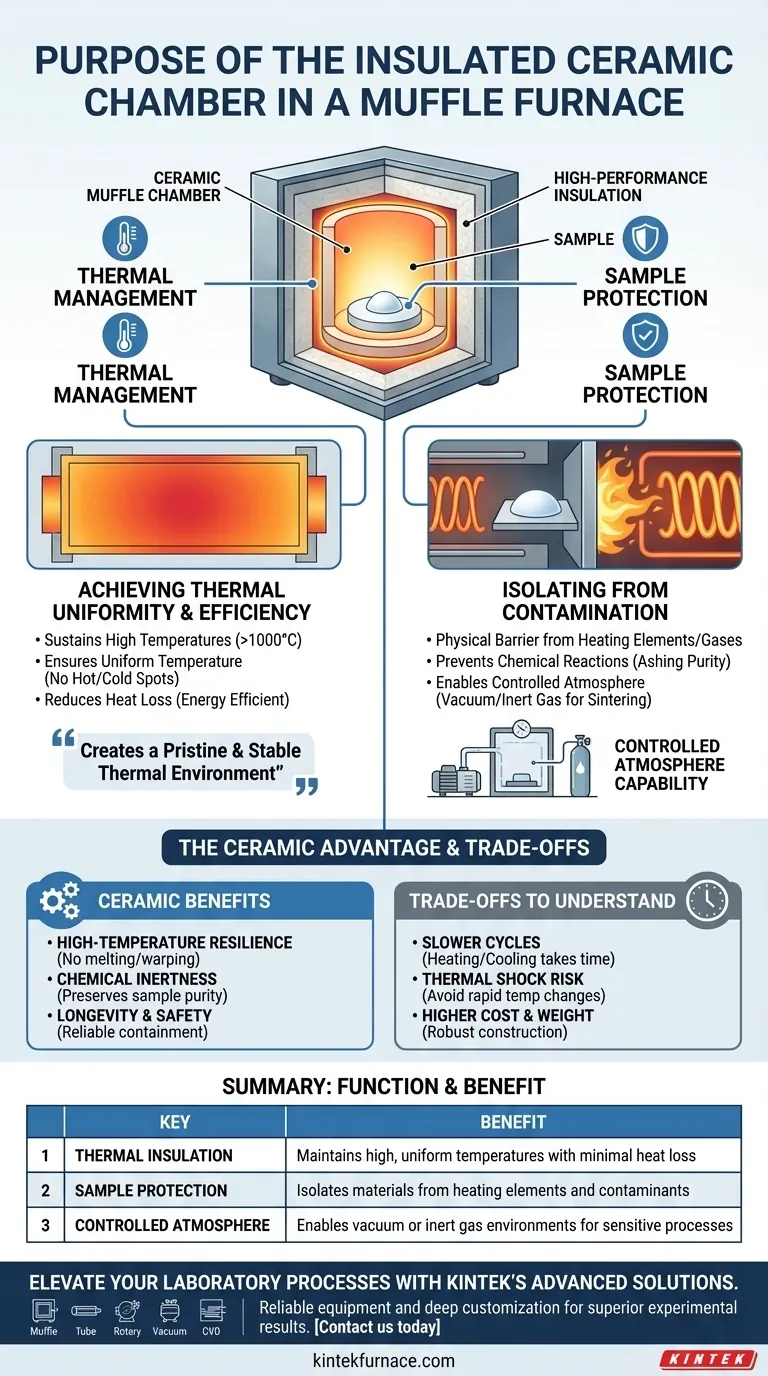

At its core, the insulated ceramic chamber in a muffle furnace serves two equally critical purposes: to maintain exceptionally high and uniform temperatures with minimal heat loss, and to isolate the material being heated from direct contact with the heating elements or any combustion byproducts. This separation, or "muffling," is the key to achieving a clean, controlled, and consistent heating environment.

The purpose of the chamber is not just to get hot, but to create a pristine and stable thermal environment. It ensures that the only variable affecting your sample is the intended, uniform temperature, free from chemical contamination or uneven heating.

The Dual Role of the Muffle Chamber

The design of the ceramic chamber, often called the "muffle," is a deliberate engineering choice that directly enables the precise work for which these furnaces are known. Its function is best understood as a combination of thermal management and sample protection.

Achieving Thermal Uniformity and Efficiency

The chamber is constructed from highly insulating ceramic materials, such as alumina fiber or polycrystalline wool. This dense insulation is exceptional at preventing heat from escaping the furnace.

This thermal efficiency provides two benefits. First, it allows the furnace to reach and sustain very high temperatures (often over 1000°C) with less energy. Second, it ensures the temperature throughout the entire chamber is uniform, eliminating hot or cold spots that could ruin an experiment.

Protecting the Sample from Contamination

The muffle acts as a physical barrier, separating the workload from the source of heat. In electric furnaces, this prevents samples from touching the glowing-hot heating elements.

In fuel-fired furnaces, this function is even more critical. The muffle shields the sample from direct exposure to flames and combustion gases, which could otherwise react with and contaminate the material. This is essential for processes like ashing, where purity is the primary goal.

Enabling a Controlled Atmosphere

Because the muffle is a sealed chamber, it provides a contained environment. This allows the user to control the atmosphere inside.

For delicate processes like sintering metal powders without oxidation, the air can be removed (creating a vacuum) or replaced with an inert gas like argon. This level of control is impossible in an open-air or directly-fired furnace.

The Criticality of Ceramic Materials

The choice of ceramic is not arbitrary; it is fundamental to the furnace's function and longevity. No other common material class offers the same combination of properties required for this application.

High-Temperature Resilience

Ceramics are defined by their ability to withstand extreme heat without melting, warping, or degrading. This ensures the structural integrity of the furnace during prolonged, high-temperature operations.

Chemical Inertness

The ceramics used are chemically inert, meaning they will not react with the samples being heated. This preserves the purity of the material, which is critical for analytical chemistry, dental restorations, and advanced materials research.

Longevity and Safety

By resisting thermal and chemical degradation, the ceramic chamber ensures the furnace has a long operational life. Its stability is also a key safety feature, reliably containing the extreme heat generated during use.

Understanding the Trade-offs

While highly effective, the design of a muffle furnace comes with practical considerations that every operator should understand.

Slower Heating and Cooling Cycles

The same heavy insulation that holds heat so effectively also makes the furnace slow to heat up and cool down. This must be factored into workflow planning, as cycles can take several hours.

Potential for Thermal Shock

While durable, ceramics can be brittle. Heating or cooling the furnace too rapidly can cause thermal shock, leading to cracks in the muffle chamber. Always follow the manufacturer's recommended ramp rates.

Higher Cost and Weight

The specialized ceramic materials and robust construction make muffle furnaces heavier and generally more expensive than simple lab ovens or directly-heated furnaces that lack a muffle.

Making the Right Choice for Your Process

Understanding the chamber's purpose helps you apply the furnace correctly to achieve your specific goal.

- If your primary focus is high-purity processing (e.g., ashing): The key benefit is the muffle's ability to isolate your sample from all potential contaminants.

- If your primary focus is repeatable heat treatment (e.g., sintering, annealing): The key benefit is the exceptional thermal uniformity that ensures consistent results every time.

- If your primary focus is material testing and development: The key benefit is the ability to create a controlled atmosphere, allowing you to manipulate the environment with precision.

Ultimately, the insulated ceramic chamber transforms a simple heat source into a precise scientific instrument.

Summary Table:

| Function | Benefit |

|---|---|

| Thermal Insulation | Maintains high, uniform temperatures with minimal heat loss |

| Sample Protection | Isolates materials from heating elements and contaminants |

| Controlled Atmosphere | Enables vacuum or inert gas environments for sensitive processes |

| Material Resilience | Uses ceramics for high-temperature durability and chemical inertness |

Elevate your laboratory processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior results. Contact us today to discuss how our furnaces can enhance your efficiency and accuracy!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency