At its core, the firing chamber of a porcelain furnace is the insulated, high-temperature compartment where dental restorations are placed to be fired. It is the principal unit of the machine, meticulously engineered to contain and control the extreme heat necessary to transform ceramic materials into a final, durable prosthetic.

The firing chamber is not merely a box that gets hot. It is a precision instrument designed to create a perfectly uniform thermal environment, which is the single most critical factor in achieving the desired strength, density, and aesthetic properties of a dental ceramic restoration.

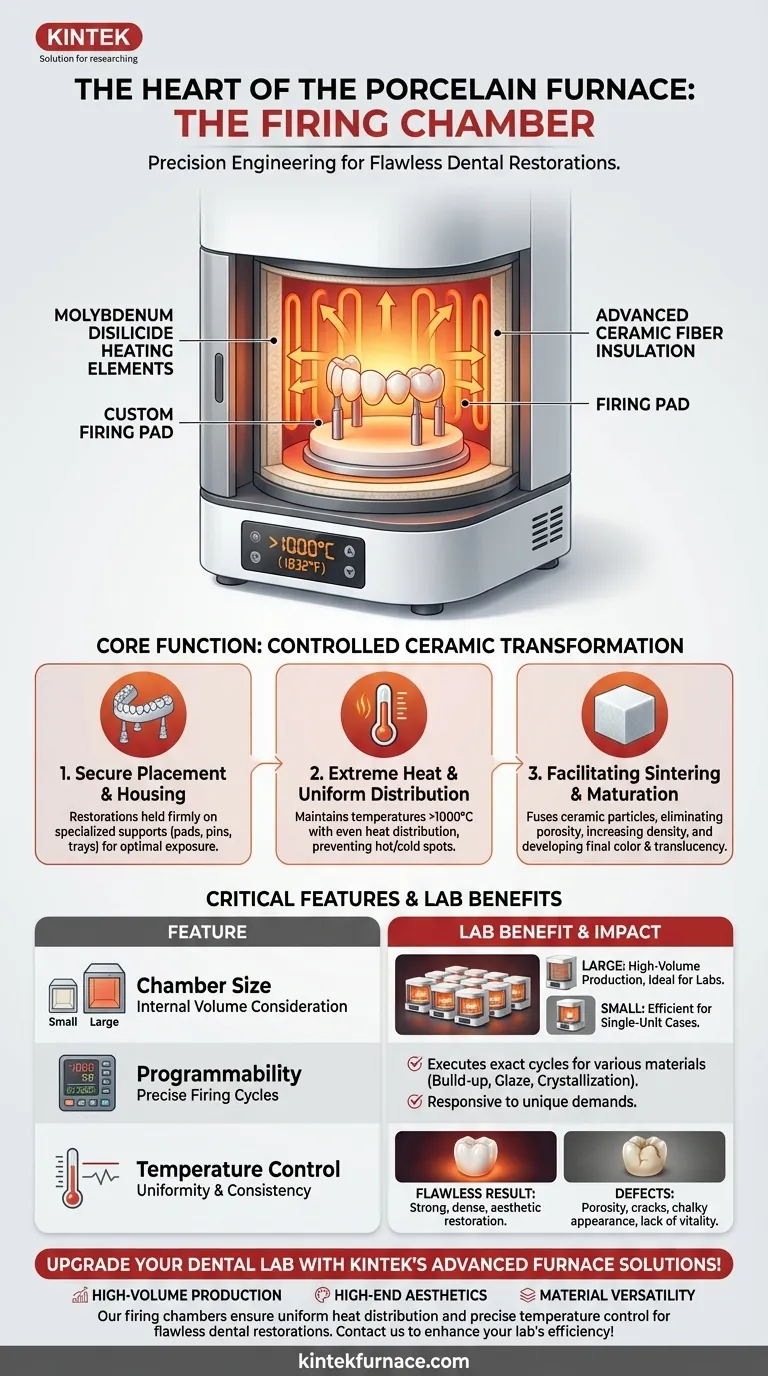

The Chamber's Role in Ceramic Transformation

The firing chamber is the active stage where the science of dental ceramics unfolds. Its design directly dictates the quality and consistency of the final restoration.

Housing the Restoration

The most fundamental purpose of the chamber is to securely hold the dental restoration during the firing cycle. Restorations are placed on specialized, heat-proof supports like firing pads, pins, or mesh trays to ensure they are positioned optimally for heat exposure.

Creating a Controlled Thermal Environment

The chamber is lined with advanced insulation, such as ceramic fiber, to withstand and maintain temperatures that can exceed 1000°C (1832°F). This thermal integrity allows the heating elements, often made of molybdenum disilicide, to raise and hold the temperature with extreme precision.

Ensuring Uniform Heat Distribution

Perhaps the most crucial function is providing even temperature distribution. Any "hot spots" or "cold spots" within the chamber will cause the ceramic to fire unevenly, leading to internal stress, cracks, poor fit, or inconsistent shades. A well-designed chamber guarantees that every surface of the restoration receives the exact same thermal treatment.

Facilitating Sintering and Maturation

This controlled environment enables sintering, the process where individual ceramic particles fuse together under heat. This process eliminates porosity, increases the material's density and hardness, and develops its final, stable color and translucency, turning a fragile powder build-up into a strong, monolithic restoration.

Understanding the Critical Trade-offs

The specifications of the firing chamber are not arbitrary. They represent a series of engineering decisions that impact a dental lab's workflow, efficiency, and final quality.

The Impact of Chamber Size

The internal volume of the firing chamber is a key consideration. A larger chamber can process more units simultaneously, which is ideal for high-production labs. However, it may consume more energy and take longer to heat and cool for a single restoration. A smaller chamber is more efficient for single-unit cases but limits throughput.

The Need for Programmability

Modern furnaces have programmable controllers that execute precise firing cycles for different materials (e.g., build-up, glaze, crystallization). The firing chamber must be able to respond rapidly and accurately to these commands, holding specific temperatures for exact durations to meet the unique demands of each ceramic system.

The Consequence of Poor Temperature Control

A failure in the chamber's ability to maintain precise and uniform temperature is the primary cause of defects. This can manifest as unwanted porosity, a chalky appearance, or a lack of vitality in the final crown or veneer. The quality of the chamber's insulation and heating elements directly correlates to the quality of your work.

Applying This to Your Lab's Goals

Understanding the firing chamber helps you evaluate a furnace based on its ability to meet your specific clinical or business objectives.

- If your primary focus is high-volume production: Prioritize a furnace with a large, durable firing chamber and proven temperature consistency across its entire volume.

- If your primary focus is high-end aesthetics: Seek a furnace renowned for its exceptional temperature uniformity and precise programmability to perfectly match complex firing schedules for advanced ceramic systems.

- If your primary focus is material versatility: Choose a furnace with a responsive firing chamber and a wide range of pre-set, manufacturer-certified programs to ensure optimal results across different brands of porcelain.

Mastering your equipment begins with understanding its core components, and the firing chamber is the heart of your furnace's performance.

Summary Table:

| Function | Key Details |

|---|---|

| Housing the Restoration | Secures restorations on heat-proof supports like firing pads or pins. |

| Controlled Thermal Environment | Uses ceramic fiber insulation and molybdenum disilicide heating elements for temperatures >1000°C. |

| Uniform Heat Distribution | Prevents hot/cold spots to avoid defects like cracks and inconsistent shades. |

| Facilitating Sintering | Fuses ceramic particles to increase density, hardness, and aesthetic properties. |

| Impact of Chamber Size | Larger chambers boost production but use more energy; smaller ones are efficient for single units. |

| Programmability | Allows precise firing cycles for different materials via programmable controllers. |

Upgrade Your Dental Lab with KINTEK's Advanced Furnace Solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you focus on high-volume production, high-end aesthetics, or material versatility, our firing chambers ensure uniform heat distribution and precise temperature control for flawless dental restorations. Contact us today to discuss how we can enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations