In essence, dental sintering and glazing furnaces are precision ovens used to transform milled dental materials into their final, functional state. They perform two distinct but critical functions: sintering, which is a high-temperature process to harden and strengthen materials like zirconia, and glazing, which is a subsequent firing to apply a smooth, aesthetic, tooth-like finish to the restoration.

These furnaces are not merely for heating; they are the crucial final step in digital dentistry that determines a restoration's strength, fit, and appearance. Sintering provides the structural integrity, while glazing provides the lifelike aesthetics.

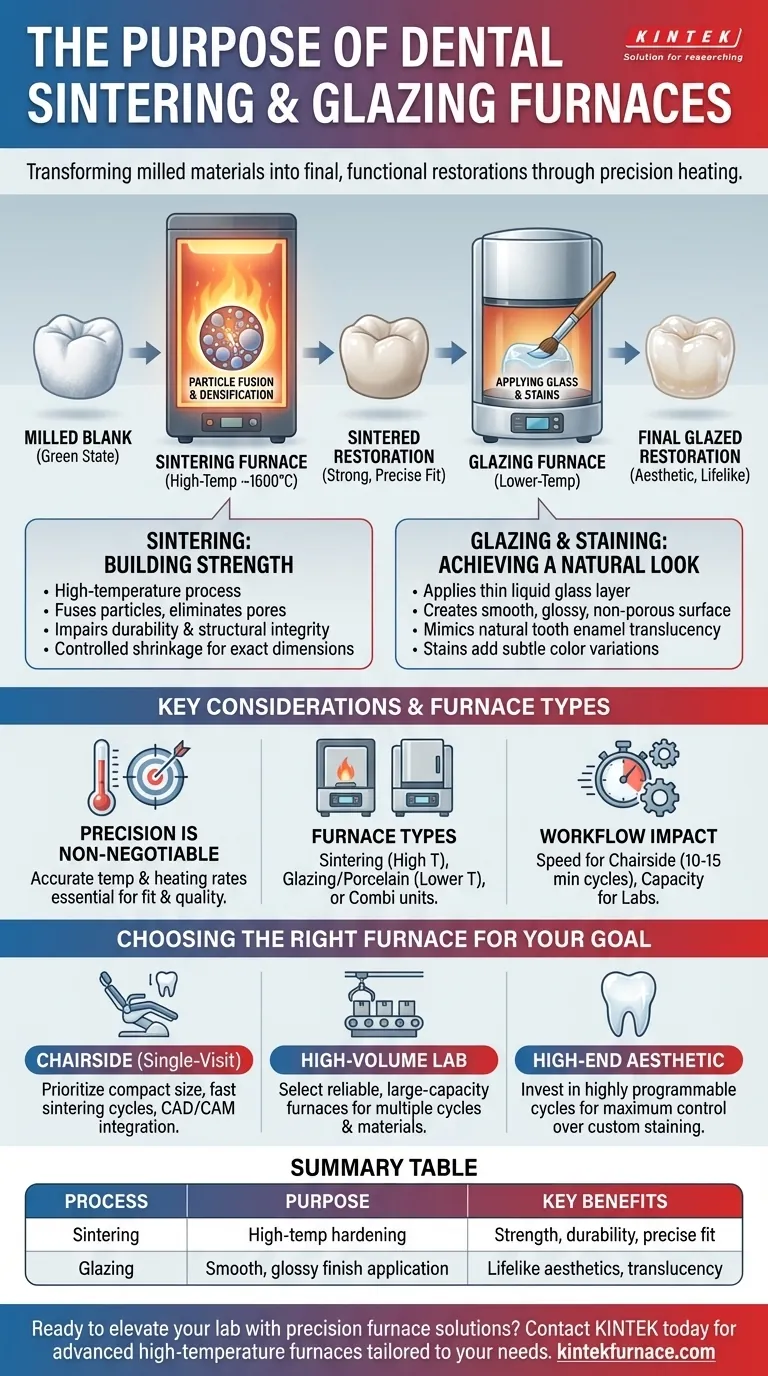

From Milled Blank to Final Restoration

A dental restoration, such as a crown or bridge, begins as a digital design that is then milled from a block of material. At this stage, the material is often in a soft, chalky, and slightly oversized form known as a "green state" or "white state." The furnace is what perfects it.

The Critical Role of Sintering: Building Strength

Sintering is a high-temperature process that fundamentally changes the physical properties of the restoration. It is the step that imparts strength and durability.

The process involves heating the material to a precise temperature just below its melting point. This causes the individual particles within the material to fuse together, eliminating pores and densifying the structure.

This is analogous to firing clay in a kiln. A soft clay pot becomes hard, durable ceramic only after being fired. Similarly, a chalky zirconia crown becomes one of the strongest materials in dentistry only after proper sintering.

As the material densifies, it shrinks to its final, exact dimensions. This controlled shrinkage is calculated in the initial design phase, making the furnace's temperature accuracy essential for a perfect fit.

The Art of Glazing & Staining: Achieving a Natural Look

After sintering, the restoration has its final strength but often lacks the luster and subtle coloration of a natural tooth. This is where glazing and staining come in.

Glazing involves applying a thin layer of liquid glass to the restoration's surface and firing it at a lower temperature. This creates a smooth, glossy, and non-porous surface that mimics the natural translucency of tooth enamel.

Stains can also be applied before this final firing. This allows a skilled technician to add subtle color variations, matching the unique characteristics of the patient's adjacent teeth for a seamless and natural-looking result.

Understanding the Key Considerations

While the concept is straightforward, the execution requires precision. The furnace's performance directly impacts the quality of the final dental work.

Precision Is Non-Negotiable

The success of sintering and glazing depends entirely on precise temperature control and consistent heating rates. An improperly calibrated furnace can lead to a weak restoration, an inaccurate fit, or poor aesthetics, wasting time and materials.

Sintering vs. Glazing Furnaces

While some "combi" furnaces can perform both functions, many dental labs use separate units. Sintering furnaces must reach very high temperatures (often up to 1600°C or higher for zirconia), while porcelain or glazing furnaces operate at lower temperatures.

Impact on Workflow and Speed

For chairside, single-visit dentistry (using systems like CEREC), fast sintering cycles are paramount. Modern furnaces with rapid heating rates can sinter a zirconia crown in as little as 10-15 minutes, making same-day restorations possible. In a production lab, capacity and reliability are more critical.

How to Apply This to Your Goal

Choosing the right furnace depends entirely on the primary function of your practice or laboratory.

- If your primary focus is single-visit chairside restorations: Prioritize a compact furnace with fast sintering cycles and seamless integration with your CAD/CAM system.

- If your primary focus is high-volume lab production: Select a reliable, large-capacity furnace that can handle a wide variety of materials and run multiple cycles efficiently.

- If your primary focus is high-end aesthetic prosthetics: Invest in a furnace with highly programmable firing cycles to give your ceramists maximum control over custom staining and glazing.

Ultimately, the right furnace transforms raw materials into the durable, lifelike restorations that define the quality of your work.

Summary Table:

| Process | Purpose | Key Benefits |

|---|---|---|

| Sintering | High-temperature hardening of materials like zirconia | Provides strength, durability, and precise fit through controlled shrinkage |

| Glazing | Application of a smooth, glossy finish | Enhances aesthetics with lifelike translucency and stain options |

Ready to elevate your dental lab or practice with precision furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored for dental professionals. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you're focused on chairside restorations, high-volume lab work, or high-end aesthetics, we can help you achieve superior results. Contact us today to discuss how our solutions can enhance your workflow and deliver durable, lifelike dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations