At its core, a dental furnace is a specialized, high-temperature oven used to transform soft, workable ceramic materials into the hard, durable final restorations that patients receive. These furnaces are the critical final step in manufacturing dental products like crowns, bridges, inlays, and onlays, ensuring they have the required strength and stability for clinical use.

The purpose of a dental furnace is not merely to heat a material, but to precisely control a thermal process called sintering. This process fundamentally changes the material's microstructure, converting a chalk-like milled block into a dense, non-porous, and exceptionally strong final restoration.

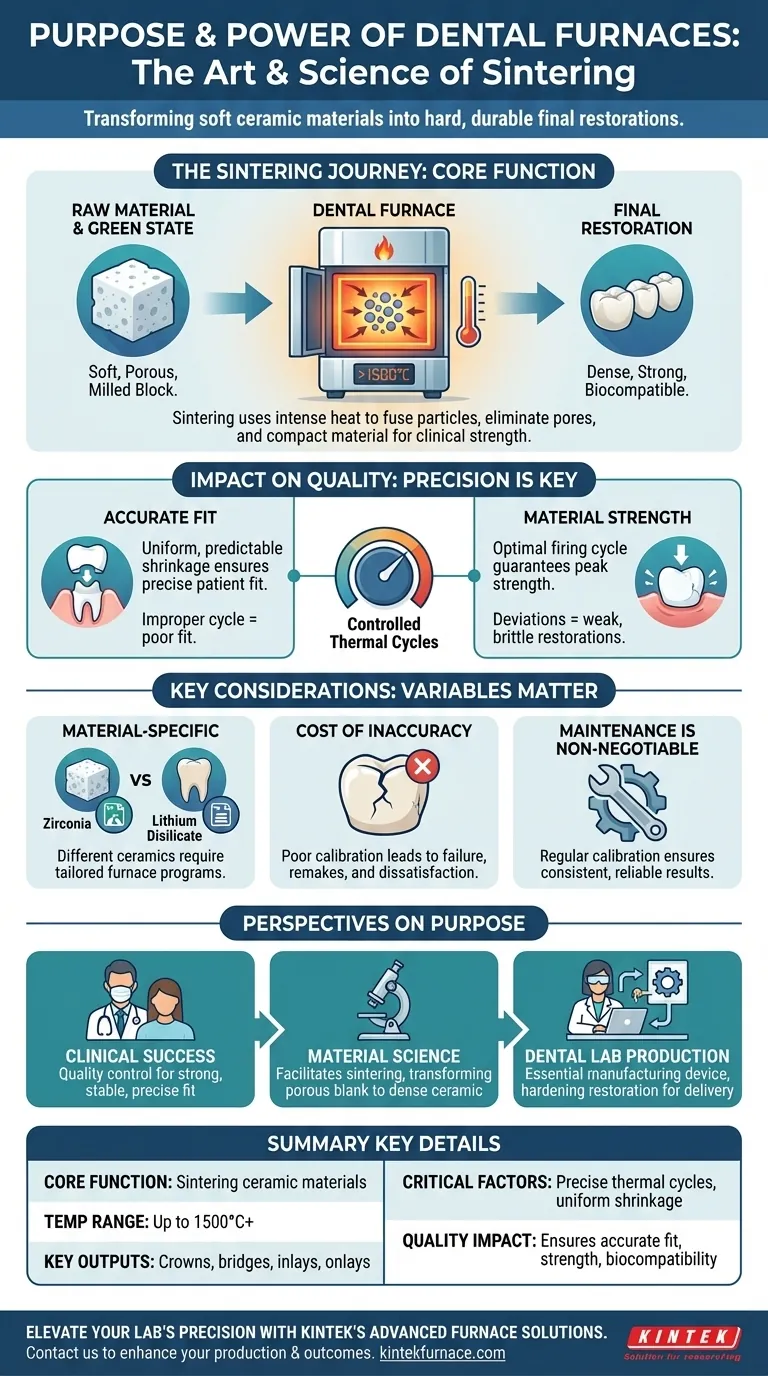

The Core Function: From Raw Material to Final Restoration

A dental furnace executes a highly specific heating and cooling program designed for a particular material. This process is what gives the final restoration its essential clinical properties.

The "Green State" Material

Before entering the furnace, materials like zirconia exist in a pre-sintered or "green state." This form is relatively soft and chalky, making it easy for a milling machine to shape it accurately into a crown or bridge. However, in this state, it is far too weak for use in the mouth.

The Sintering Process

The furnace's primary job is to initiate sintering. During this process, the furnace heats the material to temperatures often exceeding 1,500°C (2,732°F). This intense heat causes the individual ceramic particles to fuse, eliminating the microscopic pores between them and compacting the material.

Achieving Final Form and Strength

As the material sinters, it shrinks and becomes incredibly dense. This transformation dramatically increases its strength, making it capable of withstanding the immense bite forces exerted during chewing. The process turns the soft, milled shape into a hardened, biocompatible final product.

How the Furnace Dictates Restoration Quality

The precision of the furnace directly impacts the success of the final restoration. It is not just about getting hot; it is about following a precise, pre-programmed thermal cycle of heating rates, hold times, and cooling rates.

Ensuring an Accurate Fit

The shrinkage that occurs during sintering must be perfectly uniform and predictable. A high-quality furnace ensures this controlled shrinkage, which is essential for the restoration to fit the patient's prepared tooth accurately. An improper firing cycle can lead to distortion and a poor fit.

Guaranteeing Material Strength

Each ceramic material has an ideal sintering temperature and duration. Deviating from this can result in an under-fired restoration that is weak and prone to fracture, or an over-fired one that is brittle. The furnace guarantees the material reaches its optimal strength and longevity.

Understanding the Key Considerations

While essential, the furnace is a precision instrument where small variables can have a significant impact on the outcome.

Not a One-Size-Fits-All Process

Different dental ceramics, such as zirconia and lithium disilicate, have vastly different sintering requirements. A dental lab must use a furnace and a firing program specifically designed for the material being processed to achieve a successful result.

The Cost of Inaccuracy

An improperly calibrated or programmed furnace is a primary source of restoration failure. This can lead to restorations that crack in the mouth, don't fit the patient, or have poor esthetics, requiring a complete remake of the work.

Maintenance is Non-Negotiable

Because their performance is so critical, dental furnaces require regular maintenance and calibration. This ensures their temperature readings are accurate and that they can consistently produce high-quality, reliable dental restorations.

The Furnace's Role in Achieving Your Goal

The furnace is the bridge between a digitally designed restoration and a clinically successful product. Its purpose depends on your specific perspective.

- If your primary focus is clinical success: The furnace is the quality control step that ensures a restoration is strong, stable, and fits the patient's mouth with precision.

- If your primary focus is material science: The furnace is the tool that facilitates sintering, transforming a porous pre-sintered blank into a dense, high-strength polycrystalline ceramic.

- If your primary focus is dental lab production: The furnace is the essential manufacturing device that completes the production process, hardening and finalizing the restoration for delivery.

Ultimately, the dental furnace is the indispensable instrument that makes modern, high-strength ceramic restorations possible.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Function | Sintering ceramic materials to achieve strength and durability |

| Temperature Range | Up to 1,500°C (2,732°F) or higher |

| Key Outputs | Crowns, bridges, inlays, onlays |

| Critical Factors | Precise thermal cycles, uniform shrinkage, material-specific programs |

| Impact on Quality | Ensures accurate fit, strength, and biocompatibility |

Elevate your dental lab's precision and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for sintering ceramics like zirconia and lithium disilicate, delivering reliable, high-quality restorations. Contact us today to discuss how our furnaces can enhance your production process and clinical outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab