At its core, a dental porcelain furnace is a highly specialized oven used by technicians to fire, or "bake," dental ceramic materials. This precisely controlled heating process transforms raw ceramic compounds into durable, lifelike dental restorations such as crowns, bridges, and veneers. It is the critical step that provides the final product with its required strength, color, and translucency.

The true function of a porcelain furnace isn't just to heat ceramic, but to meticulously control temperature, time, and atmosphere. This precision is what allows a technician to replicate the complex interplay of strength and aesthetics found in a natural tooth.

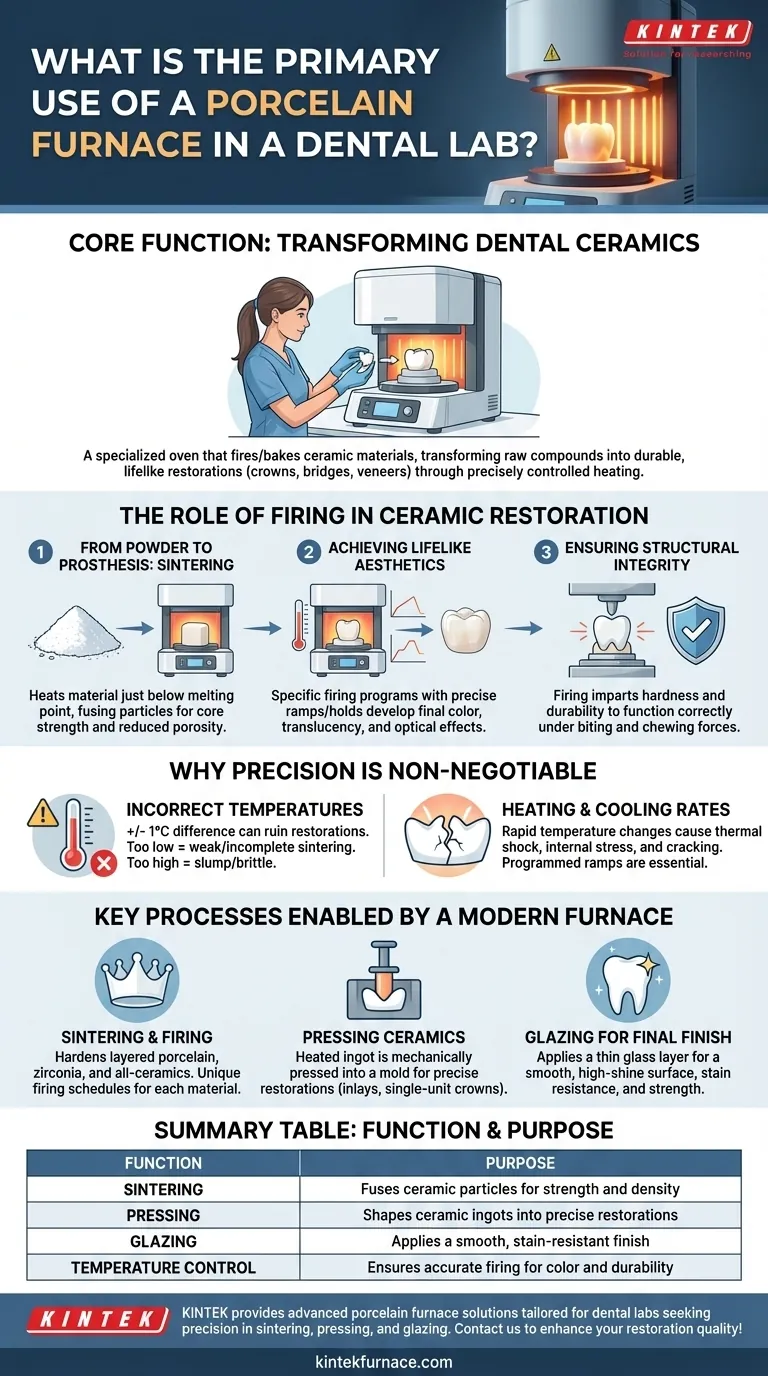

The Role of Firing in Ceramic Restoration

A porcelain furnace is the central instrument in the creation of high-quality ceramic prosthetics. Its function goes far beyond simple heating, as it orchestrates the transformation of materials at a microscopic level.

From Powder to Prosthesis: The Sintering Process

Dental ceramics often begin as a fine powder or a pre-formed block. The furnace executes a process called sintering, where it heats the material to a high temperature just below its melting point.

This causes the individual ceramic particles to fuse, drastically reducing porosity and forming a dense, solid mass. This is the fundamental step that gives the restoration its core strength.

Achieving Lifelike Aesthetics

A key goal of any dental restoration is to blend in seamlessly with the patient's natural teeth. The furnace's firing cycle is crucial for developing the final color and translucency.

Technicians use specific firing programs—with precise temperature holds and ramps—to achieve the desired optical effects, ensuring the final crown or veneer looks natural and not like a flat, opaque piece of plastic.

Ensuring Structural Integrity

The firing process imparts the necessary hardness and durability for the restoration to function correctly inside the mouth.

An improperly fired ceramic will be weak, brittle, and prone to fracture under the normal forces of biting and chewing. A correct firing cycle ensures the final product is a long-lasting and reliable medical device.

Key Processes Enabled by a Modern Furnace

Modern furnaces are programmable and versatile, capable of performing several distinct processes required in the fabrication of different restorations.

Sintering and Firing

This is the primary function, used for hardening layered porcelain, full-contour zirconia crowns, and other all-ceramic materials. Each type of ceramic requires a unique, pre-defined firing schedule for optimal results.

Pressing Ceramics

Many furnaces are also "combi" or "press" furnaces. In this process, a heated ceramic ingot is mechanically pressed into a mold to create an extremely precise restoration, such as an inlay or a single-unit crown. The furnace provides the uniform heat necessary to plasticize the ceramic for pressing.

Glazing for a Final Finish

The final step in fabrication is often a glaze fire. The restoration is coated with a thin layer of glass and fired at a specific temperature. This creates a smooth, non-porous, and high-shine surface that mimics natural tooth enamel, improves stain resistance, and increases strength.

Understanding the Trade-offs: Why Precision is Non-Negotiable

The success of a ceramic restoration is entirely dependent on the precision of the furnace. Even minor deviations can lead to a complete failure of the product.

The Risk of Incorrect Firing Temperatures

A difference of just a few degrees can ruin a restoration. Modern furnaces maintain accuracy within +/- 1° Celsius for this reason.

If the temperature is too low, the ceramic will not fully sinter and will be weak. If it is too high, it can slump, lose its form, or become overly glassy and brittle.

The Impact of Heating and Cooling Rates

Thermal shock is a major risk. If the ceramic is heated or cooled too quickly, internal stresses can build up and cause it to crack. The furnace's ability to be programmed with specific heating and cooling ramps is essential to prevent this.

Material-Specific Program Requirements

There is no "one-size-fits-all" firing cycle. Materials like zirconia and lithium disilicate have vastly different and highly specific thermal requirements. A reliable furnace must be able to accurately store and execute dozens of these unique programs without error.

Making the Right Choice for Your Goal

The right furnace depends entirely on the types of restorations your dental laboratory produces and the level of quality you aim to achieve.

- If your primary focus is high-volume crown and bridge work: Prioritize a furnace with robust programmability, a large chamber capacity, and proven reliability for repeatable sintering cycles.

- If your primary focus is high-end aesthetic cases (veneers, custom shades): Invest in a furnace with the highest degree of temperature precision and customizable glazing programs to achieve perfect translucency and color matching.

- If your lab is a multi-purpose facility: A combination furnace that expertly handles both conventional firing and pressing offers the most versatility for processing different types of ceramic materials.

Ultimately, the porcelain furnace is the critical tool that bridges the gap between raw material and a functional, aesthetic dental restoration.

Summary Table:

| Function | Purpose |

|---|---|

| Sintering | Fuses ceramic particles for strength and density |

| Pressing | Shapes ceramic ingots into precise restorations |

| Glazing | Applies a smooth, stain-resistant finish |

| Temperature Control | Ensures accurate firing for color and durability |

Ready to elevate your dental lab's capabilities? KINTEK provides advanced porcelain furnace solutions with exceptional R&D and in-house manufacturing. Our products, including customizable Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are tailored for dental labs seeking precision in sintering, pressing, and glazing for crowns, bridges, and veneers. Contact us today to discuss how our high-temperature furnaces can enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns