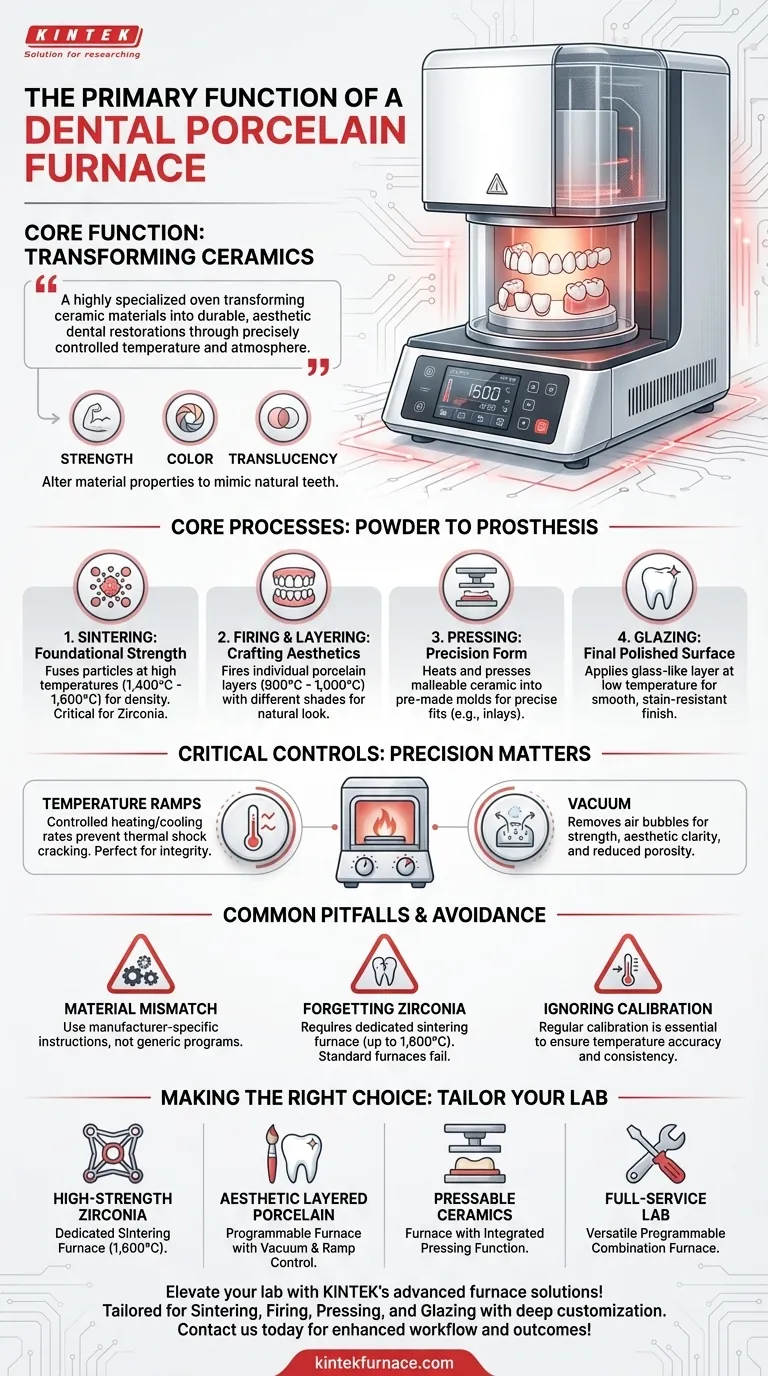

At its core, a dental porcelain furnace is a highly specialized oven engineered for the critical task of transforming ceramic materials into durable, aesthetic dental restorations. It uses precisely controlled temperature cycles and atmospheric conditions to fire, sinter, and process materials like porcelain and zirconia, creating finished products such as crowns, bridges, and veneers.

The furnace's true function is not merely heating; it is to fundamentally alter a material's properties. By meticulously managing temperature, it fuses microscopic particles to achieve the exact combination of strength, color, and translucency required for a restoration to look and function like a natural tooth.

The Core Processes: From Powder to Prosthesis

A dental furnace is not a simple "set and forget" device. It executes several distinct thermal processes, each contributing a specific quality to the final restoration.

Sintering: Building Foundational Strength

Sintering is the process of heating a material to a high temperature, just below its melting point. This causes the individual particles to fuse, dramatically increasing the material's density and strength.

This is especially critical for materials like zirconia, which are sintered at very high temperatures (1,400°C to 1,600°C) to achieve their exceptional durability for crowns and bridges.

Firing & Layering: Crafting Aesthetics

For restorations where aesthetics are paramount, technicians often build up porcelain in layers. Each layer may have a different shade or translucency to mimic the complexity of a natural tooth.

The furnace is used to fire each layer individually at a precise temperature (typically 900-1000°C), hardening it before the next one is applied.

Pressing: Achieving Precision Form

In this technique, a ceramic ingot is heated until it becomes malleable. The furnace then uses integrated mechanical pressure to press the softened ceramic into a pre-made mold or die.

This method is highly effective for creating incredibly precise and well-fitting restorations like inlays, onlays, and single crowns.

Glazing: The Final Polished Surface

The final step is often a glaze fire. A thin layer of glass-like material is applied to the restoration and fired at a relatively low temperature.

This creates a smooth, non-porous, and high-shine surface that resists staining and feels natural to the patient.

Understanding the Key Controls

The success of any restoration depends on the furnace's ability to precisely manage two critical variables: temperature and atmosphere. This control is what separates a high-quality outcome from a failure.

The Importance of Temperature Ramps

A firing cycle is not just about reaching a peak temperature. The rate of heating and cooling (the "ramps") is equally important.

If a ceramic piece is heated or cooled too quickly, the resulting thermal shock will cause it to crack. Programmable furnaces allow technicians to control these rates perfectly, ensuring the integrity of the restoration.

The Role of a Vacuum

Many firing cycles are performed under a vacuum. Pulling the air out of the firing chamber removes impurities and prevents microscopic air bubbles from becoming trapped within the porcelain.

A restoration fired without a proper vacuum can be weaker, porous, and have a cloudy or opaque appearance, compromising both its strength and its aesthetic value.

Common Pitfalls to Avoid

Even with advanced equipment, user error or a misunderstanding of the material can lead to poor outcomes. The furnace is only as good as the protocol it is given.

Material Mismatch

Different ceramic systems from different manufacturers have unique firing requirements. Using a generic program for a specialized material is a common cause of failure.

Always refer to the manufacturer's specific instructions for temperatures, ramp rates, and hold times.

Forgetting Zirconia's Needs

Standard porcelain furnaces cannot reach the extremely high temperatures required to properly sinter zirconia. Attempting to do so will result in a weak, chalky framework that is clinically unusable.

Labs working with zirconia must invest in a dedicated sintering furnace capable of maintaining temperatures up to 1,600°C.

Ignoring Calibration

Over time, a furnace's thermostat can drift, meaning the displayed temperature no longer matches the actual temperature inside the chamber.

Regular calibration is essential to ensure that firing cycles are accurate and repeatable. An uncalibrated furnace is a primary source of inconsistent results, from incorrect shading to outright cracking.

Making the Right Choice for Your Goal

The ideal furnace depends entirely on the type of work you produce. Aligning the equipment's capabilities with your lab's primary output is the key to an efficient workflow.

- If your primary focus is high-strength zirconia frameworks: You need a dedicated sintering furnace that can reliably reach and hold temperatures of 1,600°C.

- If your primary focus is aesthetic layered porcelain (PFM or all-ceramic): Your priority is a programmable furnace with exceptional vacuum capability and precise control over temperature ramps.

- If your primary focus is pressable ceramics: You require a furnace with an integrated pressing function that combines heat and mechanical force accurately.

- If you are a full-service lab: A versatile, programmable combination furnace that can handle firing, pressing, and glazing is the most efficient and space-saving investment.

Ultimately, mastering the dental furnace is fundamental to consistently delivering restorations that are both functionally sound and aesthetically exceptional.

Summary Table:

| Process | Key Function | Typical Temperature Range |

|---|---|---|

| Sintering | Fuses particles for strength | 1,400°C - 1,600°C |

| Firing & Layering | Hardens layers for aesthetics | 900°C - 1,000°C |

| Pressing | Shapes ceramics with pressure | Varies by material |

| Glazing | Creates smooth, stain-resistant surface | Low temperature |

Elevate your dental lab's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored for sintering, firing, pressing, and glazing. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Whether you focus on zirconia frameworks, layered porcelain, or full-service restorations, KINTEK delivers precision and reliability. Contact us today to discuss how we can enhance your workflow and outcomes!

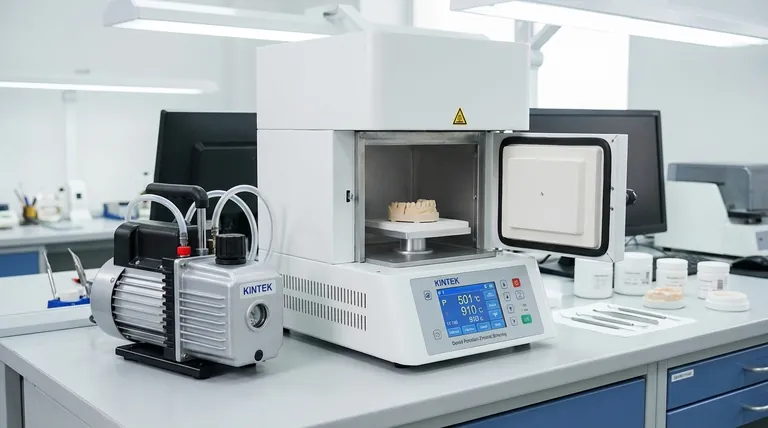

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency