At its core, a vacuum furnace offers a significant reduction in direct environmental pollution compared to traditional atmosphere-based furnaces. By operating in a near-total vacuum, it eliminates the combustion byproducts and process gases associated with conventional heat treatment, resulting in a cleaner on-site operational footprint.

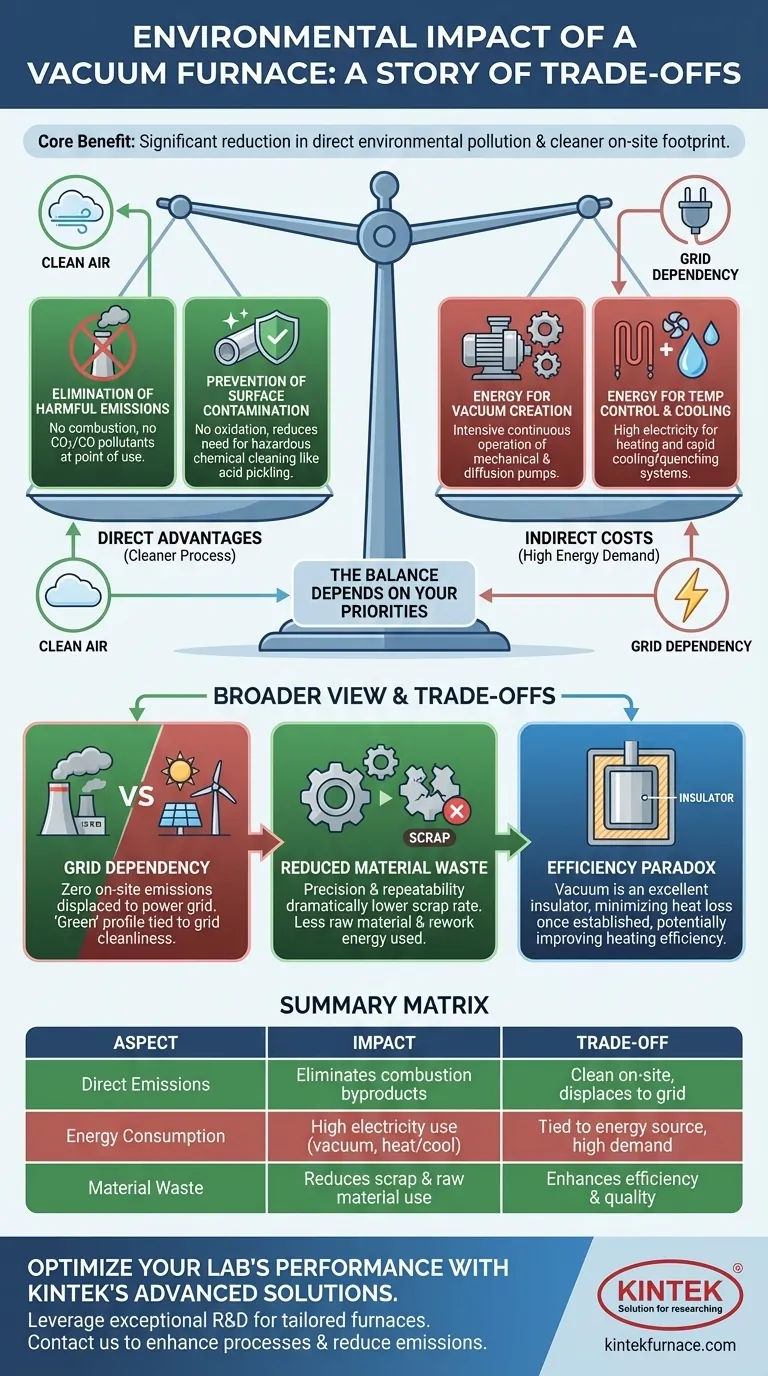

The true environmental impact of a vacuum furnace is a story of trade-offs. While it eradicates direct, on-site emissions, it shifts the environmental burden to high electricity consumption, making its overall "green" profile dependent on the energy source and its ability to reduce material waste.

The Direct Environmental Advantages

A vacuum furnace's primary environmental benefit stems from what it removes from the process: the atmosphere itself. This leads to two key advantages.

### Elimination of Harmful Emissions

Traditional furnaces often burn fuel or use protective gas atmospheres, releasing carbon dioxide (CO2), carbon monoxide (CO), and other pollutants. A vacuum furnace, by its nature, has no combustion and therefore no direct fuel-related emissions, making it a pollution-free alternative at the point of use.

### Prevention of Surface Contamination

The vacuum environment prevents oxygen and other reactive gases from interacting with the material's surface. This eliminates oxidation, decarburization, and other forms of contamination that often require secondary cleaning processes like acid pickling or shot blasting, thereby reducing the use and disposal of hazardous chemicals.

The Indirect Environmental Cost: Energy Consumption

The "clean" operation of a vacuum furnace comes at the cost of significant electrical energy demand. This impact occurs in two main areas.

### The Energy Required for Vacuum

Creating and maintaining a high-quality vacuum is an energy-intensive process. Powerful mechanical pumps and diffusion pumps must run continuously throughout the cycle to remove air molecules from the chamber, representing a substantial portion of the furnace's total energy consumption.

### The Energy of Temperature Control and Cooling

While the vacuum acts as an excellent insulator (which can improve heating efficiency), the system still requires large amounts of electricity for its heating elements. Furthermore, many processes require rapid cooling or "quenching," which often involves powerful fans or water-cooling systems, adding another layer of energy and resource demand.

Understanding the Trade-offs: A Broader View of Impact

Evaluating the environmental impact requires looking beyond just direct emissions or energy use. The true calculus involves a more holistic assessment of the entire manufacturing lifecycle.

### Direct Emissions vs. Grid Dependency

The environmental benefit of zero on-site emissions is clear. However, this cleanliness displaces the environmental impact to the power grid. A vacuum furnace running on electricity generated from fossil fuels is simply outsourcing its emissions, not eliminating them. Its green credentials are thus directly tied to the cleanliness of the local energy grid.

### High Initial Cost vs. Reduced Material Waste

Vacuum furnaces deliver unparalleled precision, repeatability, and control. This results in superior material properties, enhanced component strength, and minimal distortion or warping.

This precision dramatically reduces the scrap rate. Fewer failed or out-of-spec parts means less wasted raw material, less wasted manufacturing energy, and less need for energy-intensive rework, providing a powerful, if indirect, environmental benefit.

### The Efficiency Paradox

There's a seeming contradiction in the furnace's energy profile. Creating the vacuum is energy-intensive. However, once established, the vacuum is an exceptional insulator, minimizing heat loss to the outside.

This can make the actual heating phase more efficient than in a conventional furnace where heat is constantly lost to the surrounding atmosphere. The overall energy balance depends entirely on the specific process, cycle time, and equipment design.

How to Evaluate the True Impact for Your Application

Choosing the right technology depends on which environmental and operational metrics you prioritize.

- If your primary focus is eliminating on-site emissions and hazardous byproducts: The vacuum furnace is a superior choice, as it completely removes direct combustion pollutants and the need for many chemical post-processing steps.

- If your primary focus is minimizing overall energy consumption: The evaluation is more complex; you must compare the vacuum furnace's high electricity demand against the total energy footprint of an atmosphere furnace, including its process gas consumption and the energy wasted on reworking scrapped parts.

- If your primary focus is reducing material waste and maximizing quality: The precision and repeatability of a vacuum furnace offer a decisive advantage by producing higher-quality, longer-lasting components with a significantly lower scrap rate.

Ultimately, a vacuum furnace trades direct, visible pollution for a higher, less visible reliance on the electrical grid, while simultaneously offering profound benefits in material efficiency.

Summary Table:

| Aspect | Environmental Impact |

|---|---|

| Direct Emissions | Eliminates combustion byproducts and process gases, reducing on-site pollution |

| Energy Consumption | High electricity use for vacuum creation, heating, and cooling, tied to grid cleanliness |

| Material Waste | Reduces scrap rates through precise control, minimizing raw material and energy waste |

| Overall Trade-offs | Shifts environmental burden to energy sources while enhancing efficiency and quality |

Optimize your lab's environmental and operational performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you reduce emissions, minimize waste, and achieve superior results. Ready to enhance your processes? Contact us today for expert consultation and discover how our solutions can benefit your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability