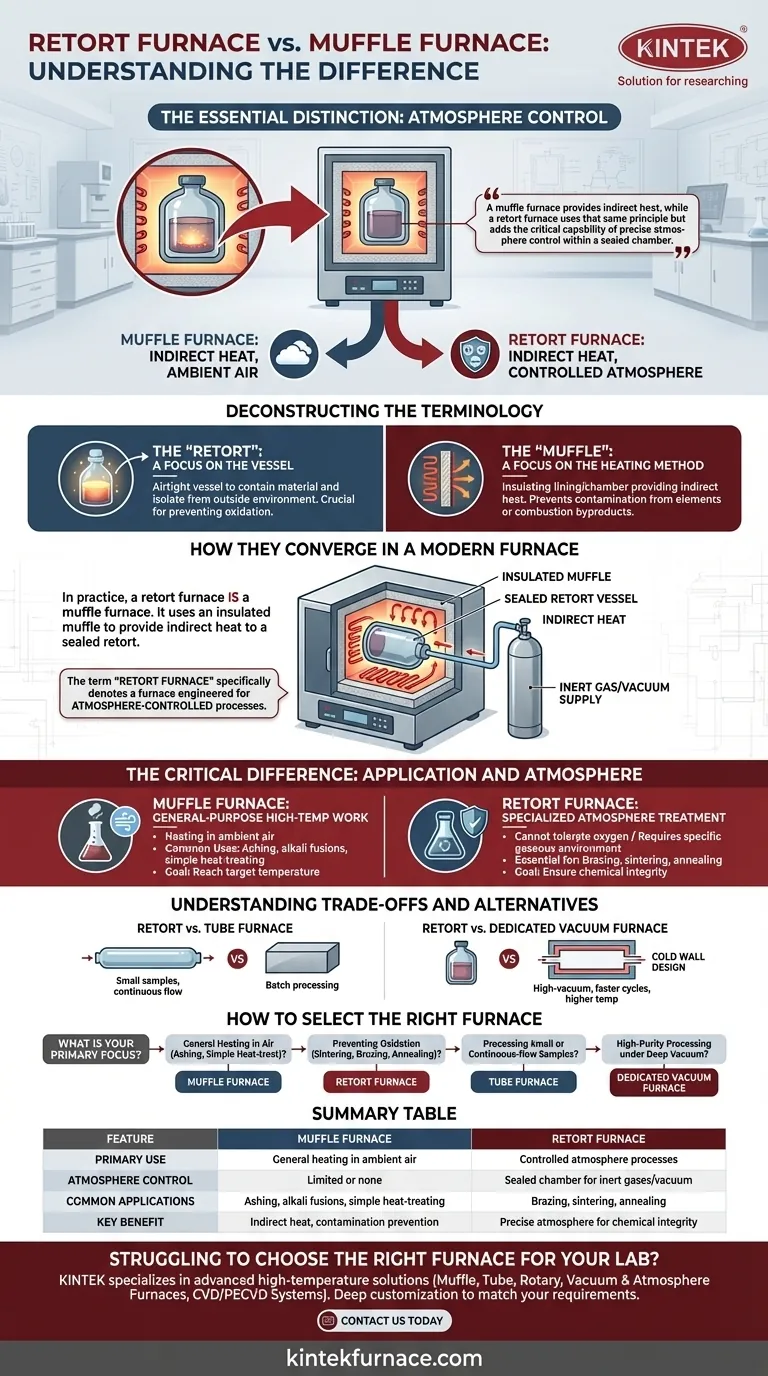

At its core, the difference between a retort furnace and a muffle furnace is more about application and specific features than fundamental design. A "retort" is the sealed vessel that holds the material, while a "muffle" is the insulating chamber that separates the heating elements from the vessel. Therefore, a modern retort furnace is a type of muffle furnace specifically designed to operate with a tightly controlled, sealed atmosphere.

The essential distinction is not in the hardware, but in the intended purpose. A muffle furnace provides indirect heat, while a retort furnace uses that same principle but adds the critical capability of precise atmosphere control within a sealed chamber.

Deconstructing the Terminology

The confusion between these terms stems from their historical origins in chemistry and manufacturing. Understanding each component clarifies their modern relationship.

The "Retort": A Focus on the Vessel

A retort is an airtight chamber or vessel. Its primary function is to contain the material being processed and isolate it from the outside environment.

This design is crucial for any process that requires a specific atmosphere, such as preventing oxidation by using an inert gas like argon or nitrogen.

The "Muffle": A Focus on the Heating Method

A muffle is the insulating lining or separate chamber that sits between the furnace's heating elements and the workload.

Its purpose is to provide indirect heat. This prevents the material from being contaminated by combustion byproducts (in a fuel-fired furnace) or being damaged by direct radiation from electric heating elements.

How They Converge in a Modern Furnace

In practice, a retort furnace is a muffle furnace. It uses an insulated muffle to provide indirect heat to a sealed retort vessel inside.

However, the industry uses the term "retort furnace" to specifically denote a furnace engineered for atmosphere-controlled processes. If a furnace is simply called a "muffle furnace," it may or may not have the sealing capabilities for precise atmosphere control.

The Critical Difference: Application and Atmosphere

Choosing between these furnaces comes down to one question: does your process require a controlled atmosphere?

Muffle Furnace: General-Purpose High-Temperature Work

A standard muffle furnace is the workhorse for applications where heating in ambient air is acceptable.

Common uses include ashing organic materials, performing alkali fusions, or simple heat-treating of non-reactive metals. The main goal is simply to reach a target temperature.

Retort Furnace: Specialized Atmosphere Treatment

A retort furnace is purpose-built for processes that cannot tolerate oxygen or require a specific gaseous environment.

This is essential for applications like brazing, sintering, and annealing. By sealing the retort and purging it with an inert gas or drawing a vacuum, you can ensure the material's chemical integrity at high temperatures.

Understanding the Trade-offs and Alternatives

While retort and muffle furnaces are common, other designs exist for more specialized needs.

Retort vs. Tube Furnace

A tube furnace is another type of furnace that is excellent for atmosphere control, but it uses a long, cylindrical tube as its chamber.

They are ideal for processing small samples, powders, or materials in a continuous flow. In contrast, retort furnaces typically use a larger box-shaped chamber for batch processing.

Retort vs. Dedicated Vacuum Furnace

While a retort furnace can be evacuated to create a low-pressure environment, a dedicated vacuum furnace is engineered for high-vacuum applications.

These often feature "cold wall" designs, where the furnace body is water-cooled. This allows for higher operating temperatures, faster heating and cooling cycles, and better temperature uniformity compared to simpler "hot wall" designs where the heat is outside the retort.

How to Select the Right Furnace for Your Process

Your choice should not be based on terminology but on the technical requirements of your work.

- If your primary focus is general heating in air (ashing, simple heat-treat): A standard, cost-effective muffle furnace is the right tool.

- If your primary focus is preventing oxidation (sintering, brazing, annealing): You must use a retort furnace designed for controlled atmospheres.

- If your primary focus is processing small or continuous-flow samples: A tube furnace offers a more suitable form factor for atmosphere control.

- If your primary focus is high-purity processing under deep vacuum: A dedicated cold-wall vacuum furnace provides superior performance and control.

Ultimately, selecting the correct furnace is about matching the equipment's capability for atmosphere control to the demands of your specific application.

Summary Table:

| Feature | Muffle Furnace | Retort Furnace |

|---|---|---|

| Primary Use | General heating in ambient air | Controlled atmosphere processes |

| Atmosphere Control | Limited or none | Sealed chamber for inert gases or vacuum |

| Common Applications | Ashing, alkali fusions, simple heat-treating | Brazing, sintering, annealing |

| Key Benefit | Indirect heat, contamination prevention | Precise atmosphere for chemical integrity |

Struggling to choose the right furnace for your lab's unique needs? KINTEK specializes in advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to precisely match your experimental requirements—ensuring optimal performance, efficiency, and reliability. Don't let equipment limitations hold you back—contact us today to discuss how we can elevate your laboratory processes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials