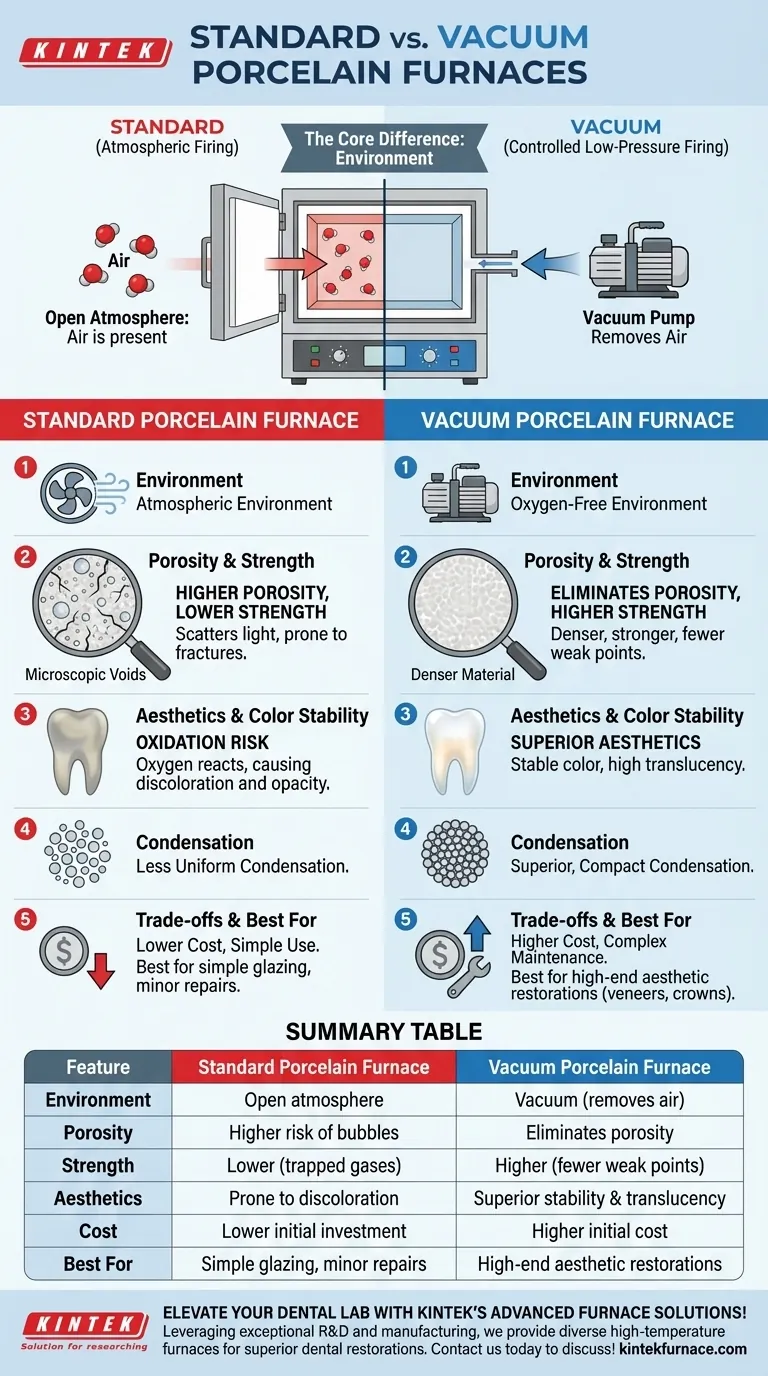

At its core, the difference between a standard porcelain furnace and a vacuum porcelain furnace is the environment in which the ceramic is fired. A standard furnace operates in the open atmosphere, while a vacuum furnace uses a pump to remove air and create a controlled, low-pressure environment. This single difference has profound implications for the quality of the final dental restoration.

While both furnaces heat ceramic to achieve hardness, the vacuum is not merely an add-on feature. It is a critical tool for eliminating microscopic flaws, ensuring the strength, and achieving the lifelike aesthetics demanded by modern dental prosthetics.

The Standard Furnace: A Foundation in Heat

A porcelain furnace is engineered for one primary purpose: to provide the precise, high-temperature environment needed to transform ceramic powder into a solid, durable restoration.

The Basic Mechanism: Muffle and Heat

Every porcelain furnace contains a muffle, which is the insulated chamber where the restoration is placed. Heating elements surrounding this chamber raise the temperature, often up to 1200°C (2200°F) or more.

This controlled heating process, known as sintering, causes the individual ceramic particles to bond and fuse together, creating a dense, vitrified structure.

The Limitation: Firing in Air

A standard, non-vacuum furnace performs this entire process in an atmospheric environment. This means the air inside the chamber is the same air that is in the room, full of oxygen, nitrogen, and other trace gases.

The Vacuum Advantage: Why Removing Air is Critical

A vacuum porcelain furnace adds a vacuum pump to this system. Before the highest temperatures are reached, the pump removes nearly all the air from the muffle. This seemingly simple step fundamentally changes the firing process and is the key to superior results.

Eliminating Porosity

As porcelain heats, gases can become trapped between the fusing particles, creating microscopic bubbles or voids. This porosity is the primary enemy of a high-quality restoration, as it scatters light (making the restoration opaque and lifeless) and creates weak points that can lead to fractures.

By firing in a vacuum, these trapped gases are physically removed from the chamber before they can be sealed into the ceramic, resulting in a significantly denser and stronger material.

Enhancing Color Stability and Translucency

The oxygen present in an atmospheric environment can react with the metallic oxides used to create specific shades in porcelain. This unwanted oxidation can cause discoloration and prevent the material from achieving its intended translucency.

A vacuum creates an oxygen-free environment, ensuring that the color remains stable and predictable. This allows for the creation of restorations that blend seamlessly with natural teeth.

Achieving Superior Condensation

The vacuum also aids in the condensation of the ceramic particles before they begin to sinter. The negative pressure helps pull the particles closer together, removing any residual air and leading to a more compact and uniform structure from the start.

Understanding the Trade-offs

While the vacuum furnace is the modern standard for high-quality work, it's important to recognize the factors involved in its operation.

Increased Complexity and Maintenance

A vacuum furnace includes additional components, such as the vacuum pump, seals, and gauges. These parts require regular maintenance and calibration to ensure the system can hold a proper vacuum, adding a layer of operational complexity.

Higher Initial Cost

The inclusion of a vacuum system naturally increases the manufacturing cost and, therefore, the purchase price of the furnace. This represents a more significant capital investment for a dental laboratory compared to a basic atmospheric furnace.

Making the Right Choice for Your Goal

The decision is less about choosing between two equal options and more about matching the equipment to the demands of the final product.

- If your primary focus is high-end aesthetic restorations (veneers, all-ceramic crowns): A vacuum furnace is non-negotiable. It is the only way to consistently achieve the low porosity, strength, and color accuracy required.

- If your work involves simple glazing or minor repairs: An atmospheric firing cycle may be sufficient, though most modern labs use their vacuum furnace for all stages, simply programming cycles that do not engage the pump.

- If you are investing in new equipment for a professional lab: A vacuum porcelain furnace is the industry standard. Choosing anything less would severely limit your ability to produce competitive, high-quality dental restorations.

Ultimately, mastering the vacuum firing process empowers you to control the physical and aesthetic properties of your restorations with unparalleled precision.

Summary Table:

| Feature | Standard Porcelain Furnace | Vacuum Porcelain Furnace |

|---|---|---|

| Environment | Operates in open atmosphere | Uses vacuum to remove air |

| Porosity | Higher risk of microscopic bubbles | Eliminates porosity for denser material |

| Strength | Lower due to trapped gases | Higher, with fewer weak points |

| Aesthetics | Prone to discoloration and opacity | Superior color stability and translucency |

| Cost | Lower initial investment | Higher initial cost |

| Best For | Simple glazing or minor repairs | High-end aesthetic restorations (e.g., veneers, crowns) |

Elevate your dental lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior dental restorations. Contact us today to discuss how our solutions can enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab