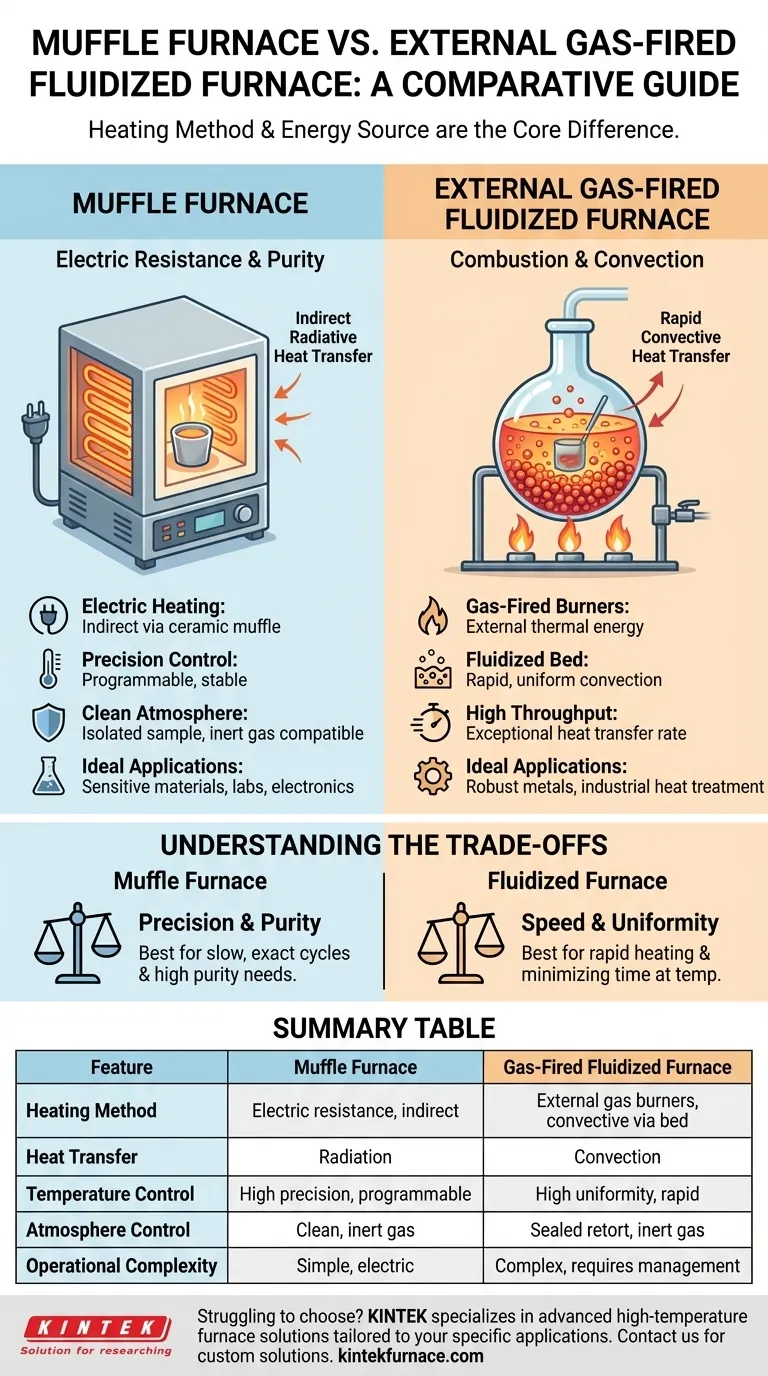

At its core, the difference between a muffle furnace and an external gas-fired fluidized furnace comes down to the heating method and heat transfer mechanism. A muffle furnace uses electric heating elements for clean, precise, indirect radiative heat, while a gas-fired fluidized furnace uses external burners to heat a bed of agitated particles that rapidly transfers heat to the sample via convection.

The choice is not simply between electric and gas. It's a fundamental decision between the high-purity, precision control of a muffle furnace and the exceptionally rapid, uniform heat transfer offered by a fluidized bed system.

The Core Difference: Heating Mechanism and Energy Source

To understand which furnace suits your application, you must first grasp how each one generates and delivers heat to your sample.

Muffle Furnace: Electric Resistance and Purity

A muffle furnace is a type of chamber or box furnace that uses electric resistance elements.

These elements heat the walls of an inner chamber, known as the muffle. This muffle, typically made of ceramic, isolates the sample from the heating elements themselves. Heat is then transferred to the sample primarily through radiation.

This indirect heating method is the muffle furnace's defining characteristic, ensuring a clean environment free from combustion byproducts and direct contact with the electrical source.

External Gas-Fired Fluidized Furnace: Combustion and Convection

This furnace uses a completely different principle. External gas burners provide the thermal energy, but they don't heat the sample directly.

Instead, the burners heat a sealed container, or retort, that holds a bed of fine, inert particles like sand or alumina. A gas is forced up through this particle bed, causing it to agitate and behave like a boiling liquid—this is the fluidized bed.

When a sample is submerged in this bed, it is touched on all sides by the hot, moving particles, resulting in extremely high rates of heat transfer through convection.

How This Impacts Your Process

The heating mechanism directly influences temperature control, atmospheric purity, and the types of materials you can process effectively.

Temperature Control and Uniformity

Electric muffle furnaces offer exceptionally precise temperature control. Modern digital controllers can execute complex temperature ramps and hold a setpoint with very high accuracy.

Fluidized bed furnaces provide unparalleled temperature uniformity. Because the sample is fully immersed in the moving particle bed, temperature gradients are virtually eliminated across the part's surface.

Atmosphere and Contamination Control

A muffle furnace is inherently clean. The sealed muffle protects the sample from any potential outgassing from the heating elements. They are ideal for creating controlled atmospheres by simply evacuating the chamber and backfilling it with an inert gas like nitrogen or argon.

A gas-fired fluidized furnace also offers excellent atmosphere control, as the entire process happens within the sealed retort. The fluidizing gas itself can be an inert gas, creating a controlled environment. However, the integrity of the retort is critical to prevent leaks.

Sample Size and Processing Speed

Muffle furnaces, being a type of box furnace, are excellent for processing larger parts or batches of samples with irregular shapes.

A key advantage of the fluidized bed furnace is its speed. The rate of heat transfer is many times higher than in a standard radiation or convection furnace, drastically reducing the time it takes for a sample to reach the desired temperature.

Understanding the Trade-offs

Neither furnace is universally superior; they are engineered for different outcomes. The choice involves clear trade-offs.

Precision vs. Heat Transfer Rate

The muffle furnace's strength is its programmable precision. It is the tool of choice for sensitive materials, delicate ceramics, or processes requiring slow, exact heating and cooling cycles.

The fluidized bed furnace's strength is its rate of heat transfer. It excels at rapidly and uniformly heating robust metal parts for processes like hardening, tempering, or annealing, where minimizing time at temperature is critical.

Operational Simplicity vs. Complexity

Muffle furnaces are generally simpler to operate. They are electric, requiring no fuel lines, exhaust flues, or burner management.

A gas-fired fluidized system is more complex. It involves managing fuel supply, combustion, exhaust, and the fluidizing gas system, which adds to maintenance requirements.

Purity vs. Throughput

The sealed, electric nature of the muffle furnace makes it ideal for applications demanding the highest purity, such as in analytical chemistry, dental labs, or electronics manufacturing.

The rapid heating of a fluidized bed furnace makes it a workhorse for industrial heat treatment where high throughput and process efficiency are the primary goals.

Making the Right Choice for Your Application

Your final decision should be guided by the most critical requirement of your process.

- If your primary focus is ultimate purity and precise temperature ramps for sensitive materials: Choose a muffle furnace for its clean, electrically controlled environment.

- If your primary focus is rapid, highly uniform heating of robust components like metals: A gas-fired fluidized furnace is superior due to its exceptional heat transfer rate.

- If your primary focus is processing large or irregularly shaped parts in a controlled atmosphere: A muffle (box) furnace offers greater geometric flexibility, though a fluidized bed can also manage this within the limits of its retort.

Understanding these core operational differences allows you to select the precise tool your process demands.

Summary Table:

| Feature | Muffle Furnace | External Gas-Fired Fluidized Furnace |

|---|---|---|

| Heating Method | Electric resistance, indirect radiative | External gas burners, convective via fluidized bed |

| Heat Transfer | Radiation | Convection |

| Temperature Control | High precision, programmable | High uniformity, rapid transfer |

| Atmosphere Control | Clean, inert gas compatible | Sealed retort, inert gas fluidizing |

| Ideal Applications | Sensitive materials, analytical labs, electronics | Robust metals, industrial heat treatment |

| Operational Complexity | Simple, electric | Complex, requires fuel and gas management |

Struggling to choose the right furnace for your lab's unique needs? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your specific applications. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you need the purity of a muffle furnace or the speed of a fluidized system. Don't settle for one-size-fits-all—contact us today to discuss how our expertise can optimize your laboratory processes and boost efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?