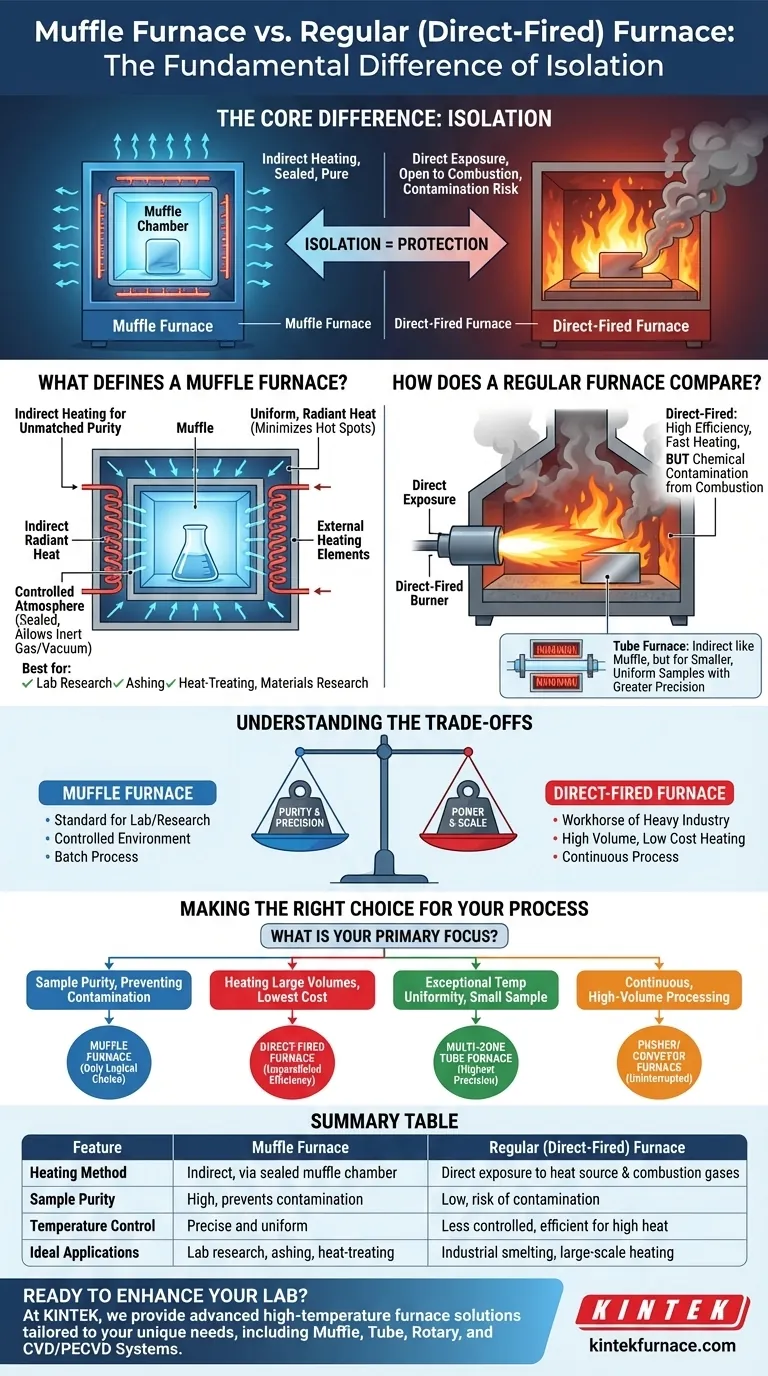

The fundamental difference is isolation. A muffle furnace heats material inside a sealed chamber (the "muffle"), completely isolating it from the heating elements and outside atmosphere. In contrast, a "regular" or direct-fired furnace exposes the material directly to the heat source and the byproducts of combustion, making it a less controlled environment.

The choice between a muffle furnace and another type is not about which is "better," but about your specific process requirements. The decision hinges on one critical question: does your material need to be protected from direct contact with the heat source and its environment?

What Defines a Muffle Furnace? The Principle of Isolation

A muffle furnace is purpose-built for processes that demand purity and precise thermal control. Its design is centered on the concept of indirect heating.

Indirect Heating for Unmatched Purity

The material, or "workpiece," is placed inside the muffle chamber. The heating elements (typically electric) are located outside this chamber.

The elements heat the chamber walls, which then radiate thermal energy evenly onto the material inside. This prevents any contamination from fuel, combustion gases, or the heating elements themselves.

Uniform, Radiant Heat

This indirect method ensures that heat is applied to the sample from all sides, minimizing hot spots and promoting exceptional temperature uniformity throughout the workload.

This is critical for sensitive processes like annealing, ashing, or growing crystals, where an even temperature gradient is paramount for consistent results.

A Controlled Atmosphere

Because the muffle is a sealed chamber, it's ideal for creating a controlled atmosphere. The air can be evacuated to create a vacuum or replaced with an inert gas like argon or nitrogen to prevent oxidation at high temperatures.

How Does a "Regular" Furnace Compare?

The term "regular furnace" most often refers to a direct-fired furnace, especially in large-scale industrial settings. However, it's useful to compare the muffle furnace to other common heating devices.

Direct-Fired Furnaces

In a direct-fired furnace, a fuel like natural gas or oil is burned, and the resulting hot gases and flames come into direct contact with the material being heated.

This is a highly efficient method for transferring a large amount of thermal energy quickly. However, it offers very little protection against chemical contamination from combustion byproducts.

Tube Furnaces: A Close Relative

A tube furnace operates on a similar principle of indirect heating but uses a narrow cylindrical tube instead of a box-shaped chamber.

While a muffle furnace is ideal for bulkier items or batches of samples, a tube furnace excels at heating smaller, uniform samples with even greater precision over temperature gradients and gas flow.

The Key Distinction is Exposure

Ultimately, the defining line is exposure. A muffle furnace shields the sample. Most other furnace types, by design or for efficiency, expose the sample directly to the heating environment.

Understanding the Trade-offs

Choosing the right furnace involves weighing the needs for purity, temperature precision, sample size, and throughput.

Muffle Furnace: Purity and Versatility

A muffle furnace is the standard for laboratory and research applications where contamination would ruin the outcome. It's perfect for processes like ashing organic materials, heat-treating high-performance alloys, and conducting materials research.

Its main limitation is that it's a batch process; materials are loaded, heated, and then removed. This makes it less suitable for continuous, high-volume manufacturing.

Direct-Fired Furnace: Power and Scale

These furnaces are the workhorses of heavy industry. They are used for smelting, large-scale casting, and other processes where the primary goal is simply to get a massive amount of material very hot, very quickly. Purity is a secondary concern.

Tube Furnace: Precision and Control

For applications requiring the absolute highest degree of temperature uniformity or carefully managed gas flow over a sample—such as chemical vapor deposition (CVD)—a tube furnace is often the superior choice. Its geometry allows for more precise control than a muffle furnace's larger box chamber.

Making the Right Choice for Your Process

Your application dictates the correct tool. Use these guidelines to make a clear decision.

- If your primary focus is sample purity and preventing contamination: The isolation provided by a muffle furnace makes it the only logical choice.

- If your primary focus is heating large volumes at the lowest cost: A direct-fired furnace offers unparalleled thermal efficiency for industrial-scale work.

- If your primary focus is exceptional temperature uniformity for a small sample: A multi-zone tube furnace provides the highest level of precision and control.

- If your primary focus is continuous, high-volume processing: A pusher or conveyor furnace is designed specifically for moving materials through a heating zone without interruption.

Selecting the right furnace is about aligning the equipment's core design with your specific scientific or industrial goal.

Summary Table:

| Feature | Muffle Furnace | Regular (Direct-Fired) Furnace |

|---|---|---|

| Heating Method | Indirect, via sealed muffle chamber | Direct exposure to heat source and combustion gases |

| Sample Purity | High, prevents contamination | Low, risk of contamination |

| Temperature Control | Precise and uniform | Less controlled, efficient for high heat |

| Ideal Applications | Lab research, ashing, heat-treating | Industrial smelting, large-scale heating |

Ready to enhance your lab's capabilities with the perfect furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in research, materials science, or industrial processing, we can help you achieve precise thermal control and superior results. Contact us today to discuss your requirements and discover how KINTEK can support your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis