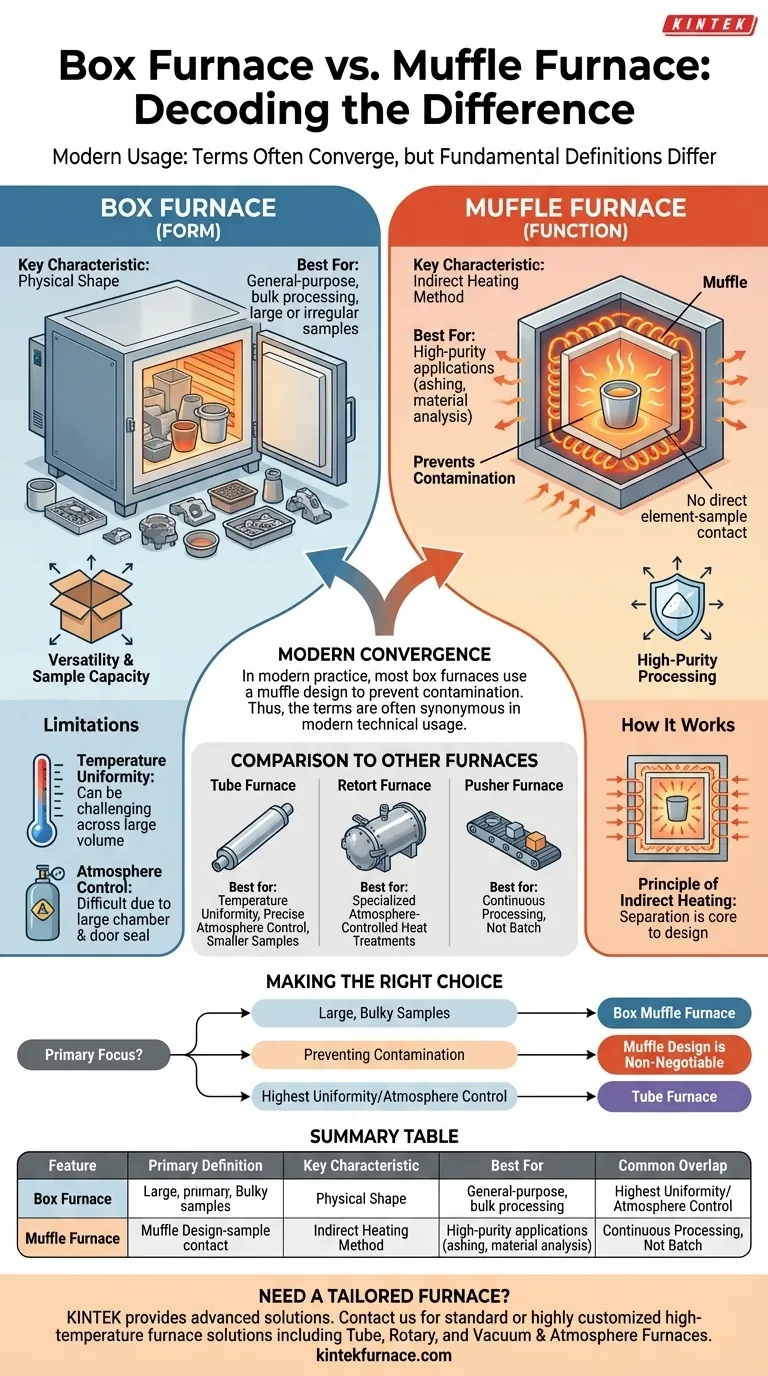

In modern technical usage, the terms "box furnace" and "muffle furnace" are often used interchangeably to describe the same equipment. A "box furnace" refers to the physical shape—a cubic or rectangular chamber—while a "muffle furnace" refers to the heating method, where the sample is isolated from the heating elements. Since most modern box furnaces incorporate this isolation principle, they are functionally muffle furnaces.

The key distinction lies in form versus function. "Box" describes the furnace's shape, which is ideal for general-purpose use. "Muffle" describes its method of indirect heating, which is critical for preventing sample contamination. In practice, the two terms have largely converged.

What Defines a Muffle Furnace?

The defining characteristic of a muffle furnace is not its shape, but its method of heating. It is designed to create a barrier between the heat source and the material being processed.

The Principle of Indirect Heating

In a muffle furnace, the sample does not come into direct contact with the heating elements or any flames. This separation is the core of the "muffle" design.

The heating elements, typically resistance wires, are wound around the outside of a ceramic chamber (the muffle) or embedded within the furnace walls.

How It Works

These elements heat the chamber, and the chamber's interior atmosphere then heats the sample through convection and radiation. This indirect process ensures a more uniform heat distribution within the chamber.

The Core Benefit: Preventing Contamination

This separation is crucial for applications where purity is paramount. It prevents byproducts of combustion or particles from the heating elements from contaminating the sample. This makes it essential for processes like ashing, material analysis, and heat-treating sensitive components.

The "Box Furnace" as a Form Factor

While "muffle" describes function, "box furnace" or "chamber furnace" simply describes its physical construction.

A Matter of Shape

These terms indicate that the furnace has a box-shaped chamber, as opposed to a long, narrow one like a tube furnace.

This shape is highly versatile, making it suitable for holding crucibles, trays, or irregularly shaped parts.

Why the Terms Converged

The box shape is an excellent general-purpose design that pairs perfectly with the indirect heating principle of a muffle. Because most modern laboratory box furnaces are built with this contamination-free muffle design, the names have become synonymous.

How a Muffle Furnace Compares to Other Furnaces

Understanding the muffle furnace's role requires comparing it to other common types of high-temperature equipment.

Muffle Furnace vs. Tube Furnace

A tube furnace is ideal for applications requiring exceptional temperature uniformity and precise atmospheric control over a smaller sample. Its cylindrical shape is easy to seal and purge with inert gases or a vacuum.

A box muffle furnace is the better choice for processing larger, bulkier, or numerous samples at once that would not fit inside a narrow tube.

Muffle Furnace vs. Retort Furnace

A retort furnace is specifically designed for atmosphere-controlled heat treatments. While a muffle furnace can be equipped for this, a retort furnace typically features a more robustly sealed metal chamber (the retort) for superior atmospheric integrity.

Muffle Furnace vs. Pusher Furnace

A box muffle furnace is a "batch" furnace, where materials are placed inside, heated for a set time, and then removed. In contrast, a pusher furnace is a "continuous" furnace, where materials are constantly pushed or moved through different heating and cooling zones.

Understanding the Trade-offs

No single furnace design is perfect for every task. The box muffle furnace has clear advantages but also specific limitations.

Advantage: Versatility and Sample Capacity

The primary strength of the box muffle furnace is its ability to accommodate a wide variety of sample sizes and shapes, from small crucibles to large industrial parts.

Advantage: High-Purity Processing

The muffle design guarantees that the sample remains isolated from the heat source, which is non-negotiable for many analytical and materials science applications.

Limitation: Temperature Uniformity

Achieving perfectly consistent temperature across a large, open box chamber can be more challenging than in the controlled environment of a multi-zone tube furnace. There may be slight temperature gradients, especially near the door.

Limitation: Atmosphere Control

While many box muffle furnaces support vacuum or inert gas flow, the large chamber volume and door seal can make achieving high-purity atmospheres more difficult and gas-intensive compared to a smaller, more easily sealed tube furnace.

Making the Right Choice for Your Application

Selecting the correct furnace depends entirely on your primary processing goal.

- If your primary focus is processing large, bulky, or irregularly shaped samples: A box muffle furnace is the ideal choice due to its spacious chamber.

- If your primary focus is preventing any contamination from the heating elements: The muffle design is non-negotiable, and most box furnaces provide this.

- If your primary focus is achieving the highest degree of temperature uniformity and atmosphere control for smaller samples: A tube furnace will likely outperform a box muffle furnace.

Understanding these core design principles allows you to select the right tool based on your specific experimental or production requirements.

Summary Table:

| Feature | Box Furnace | Muffle Furnace |

|---|---|---|

| Primary Definition | Describes physical shape (cubic/rectangular chamber) | Describes heating method (indirect, sample isolation) |

| Key Characteristic | Versatile for large/irregular samples | Prevents contamination via indirect heating |

| Best For | General-purpose, bulk sample processing | High-purity applications like ashing, material analysis |

| Common Overlap | Most modern box furnaces incorporate muffle design principles | Often built in a box-shaped form factor for versatility |

Need a high-temperature furnace tailored to your unique lab requirements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced solutions for diverse laboratories. Whether you need a standard Muffle or Box Furnace, or a highly customized system, our product line—including Tube Furnaces, Rotary Furnaces, and Vacuum & Atmosphere Furnaces—is designed to meet your exact needs.

Our strong deep customization capability ensures we can precisely adapt our furnaces to your specific experimental or production goals, from sample size and purity requirements to temperature uniformity and atmosphere control.

Contact us today to discuss how KINTEK's high-temperature furnace solutions can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?