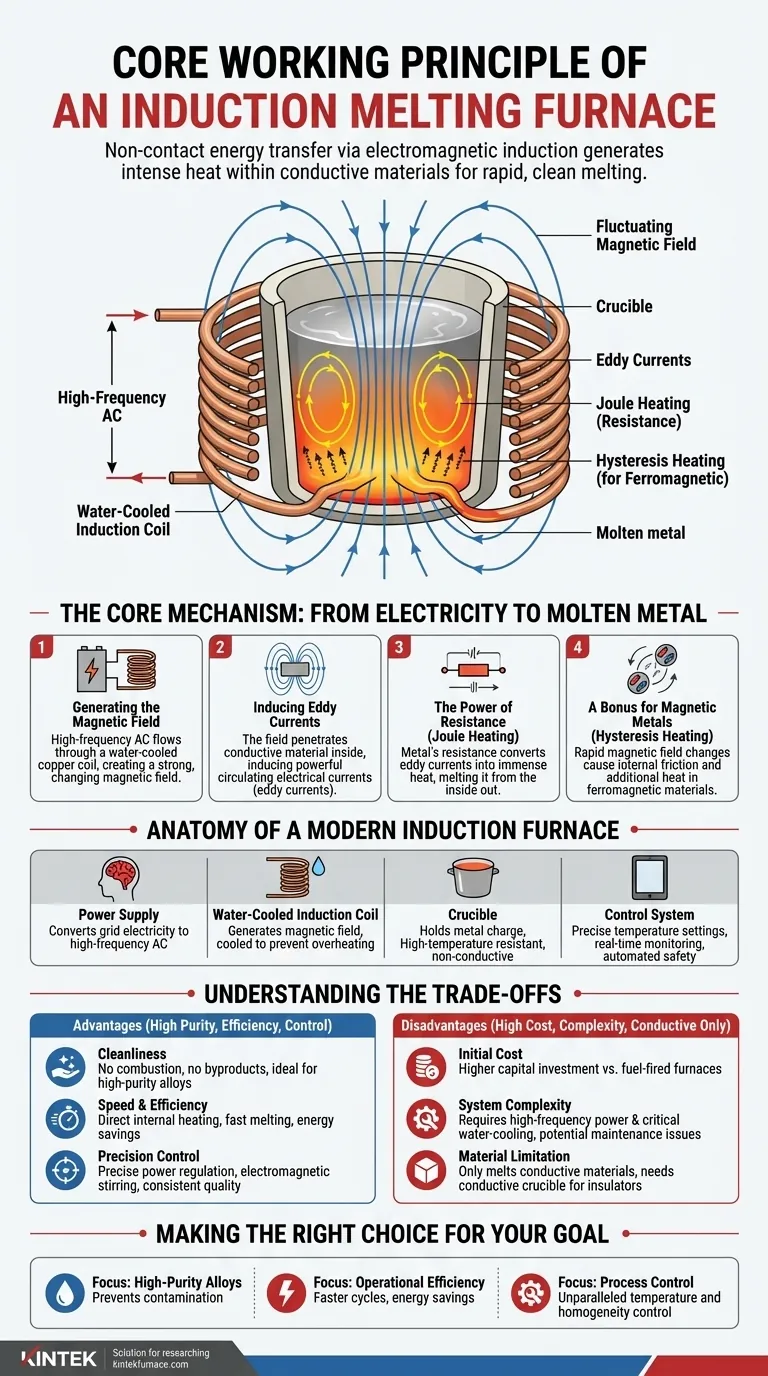

At its core, an induction melting furnace works like a powerful, specialized microwave for metals. It uses the principle of electromagnetic induction to generate intense heat directly inside the conductive material itself, melting it rapidly and cleanly without any physical contact from a heating element or flame.

The central principle is non-contact energy transfer. A fluctuating magnetic field induces powerful electrical currents (eddy currents) within the metal, and the metal's own electrical resistance converts this current into heat, causing it to melt from the inside out.

The Core Mechanism: From Electricity to Molten Metal

Understanding the process step-by-step reveals an elegant application of physics that is both efficient and highly controllable.

Generating the Magnetic Field

A high-frequency alternating current (AC) is passed through a water-cooled copper coil. This flow of electricity creates a strong, rapidly changing magnetic field in the space within and around the coil.

Inducing Eddy Currents

When an electrically conductive material, such as steel or aluminum, is placed inside this magnetic field, the field penetrates the metal. This induces circulating electrical currents within the material, known as eddy currents.

The Power of Resistance (Joule Heating)

All materials have some electrical resistance. As the powerful eddy currents flow through the metal, they encounter this resistance and generate immense heat. This phenomenon, known as Joule heating, is the primary source of the melting energy.

A Bonus for Magnetic Metals (Hysteresis Heating)

For ferromagnetic materials like iron, an additional heating effect occurs. The rapidly changing magnetic field forces the magnetic domains within the iron to constantly realign, creating internal friction and generating supplementary heat. This is called hysteresis heating.

Anatomy of a Modern Induction Furnace

A furnace is more than just a coil. It is a complete system where each component plays a critical role in ensuring an efficient, safe, and controlled melt.

The Power Supply

This is the brain of the operation. It converts standard grid electricity (e.g., 50/60 Hz) into the high-frequency AC (from 50 Hz up to 1100 kHz) required to drive the induction coil effectively.

The Water-Cooled Induction Coil

The copper coil carries enormous electrical current and would quickly overheat and melt itself. A closed-loop water cooling system continuously circulates water through the hollow coil to dissipate this heat, protecting the most vital component of the furnace.

The Crucible

This is the non-conductive, high-temperature-resistant container that holds the metal charge. It is typically made from ceramic or graphite materials that can withstand the extreme temperatures of molten metal without reacting with it.

The Control System

Modern furnaces rely on sophisticated control panels for precision. These systems allow for programmable temperature settings, real-time monitoring of the melt, and automated safety features, ensuring consistent quality and operational safety.

Understanding the Trade-offs

While powerful, induction technology has specific characteristics that make it ideal for some applications and less suitable for others.

High Purity vs. High Cost

The primary advantage of induction is cleanliness. With no combustion, there are no byproducts like carbon or sulfur to contaminate the melt, making it ideal for high-purity alloys. This technological sophistication, however, often comes with a higher initial capital cost compared to traditional fuel-fired furnaces.

Efficiency vs. Complexity

The direct internal heating is extremely energy-efficient and fast. However, the system's reliance on a high-frequency power supply and a critical water-cooling circuit introduces complexity. A failure in either of these support systems can halt production and require specialized maintenance.

Conductive Materials Only

The entire principle is based on electromagnetic induction. Therefore, the furnace can only directly melt electrically conductive materials. It cannot be used to melt insulators like glass or certain ceramics without the use of a conductive crucible to act as a secondary heater.

Making the Right Choice for Your Goal

Understanding the core principle empowers you to align the technology with your specific manufacturing needs.

- If your primary focus is high-purity alloys: The combustion-free, non-contact heating of an induction furnace is its greatest strength, as it prevents contamination of the melt.

- If your primary focus is operational efficiency: The speed and direct heating mechanism of induction furnaces offer significant energy savings and faster production cycle times.

- If your primary focus is process control: The precise power regulation and natural electromagnetic stirring provide unparalleled control over melt temperature and alloy homogeneity.

By grasping how electricity is transformed into a controlled magnetic field to melt metal internally, you can make an informed decision on whether this technology is the right tool for your objective.

Summary Table:

| Component | Core Function | Key Characteristic |

|---|---|---|

| Power Supply | Converts grid electricity to high-frequency AC | Enables precise control of the magnetic field |

| Induction Coil | Generates a fluctuating magnetic field | Water-cooled to handle high electrical currents |

| Crucible | Holds the metal charge during melting | Made from high-temperature resistant, non-conductive materials |

| Control System | Manages temperature and monitors the melt process | Ensures operational safety and consistent quality |

Ready to leverage the power of electromagnetic induction for your melting needs? KINTEK's advanced high-temperature furnace solutions, including our robust induction melting systems, are engineered for precision, purity, and efficiency. With our exceptional R&D and in-house manufacturing capabilities, we provide deep customization to meet your unique experimental and production requirements. Contact our experts today to discuss how our technology can enhance your metal melting processes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys