Ultimately, the choice of a dental sintering furnace is a critical investment that directly dictates the quality, longevity, and structural integrity of the final dental restorations. A furnace is not simply a tool for heating; it is the device responsible for transforming materials into their final, durable state. Making the wrong choice can compromise the entire production process, leading to poor clinical outcomes.

The right furnace is defined not by its price or features, but by its ability to deliver precise and repeatable temperature cycles. This precision is the foundation for creating strong, aesthetically pleasing, and durable dental restorations that meet clinical standards.

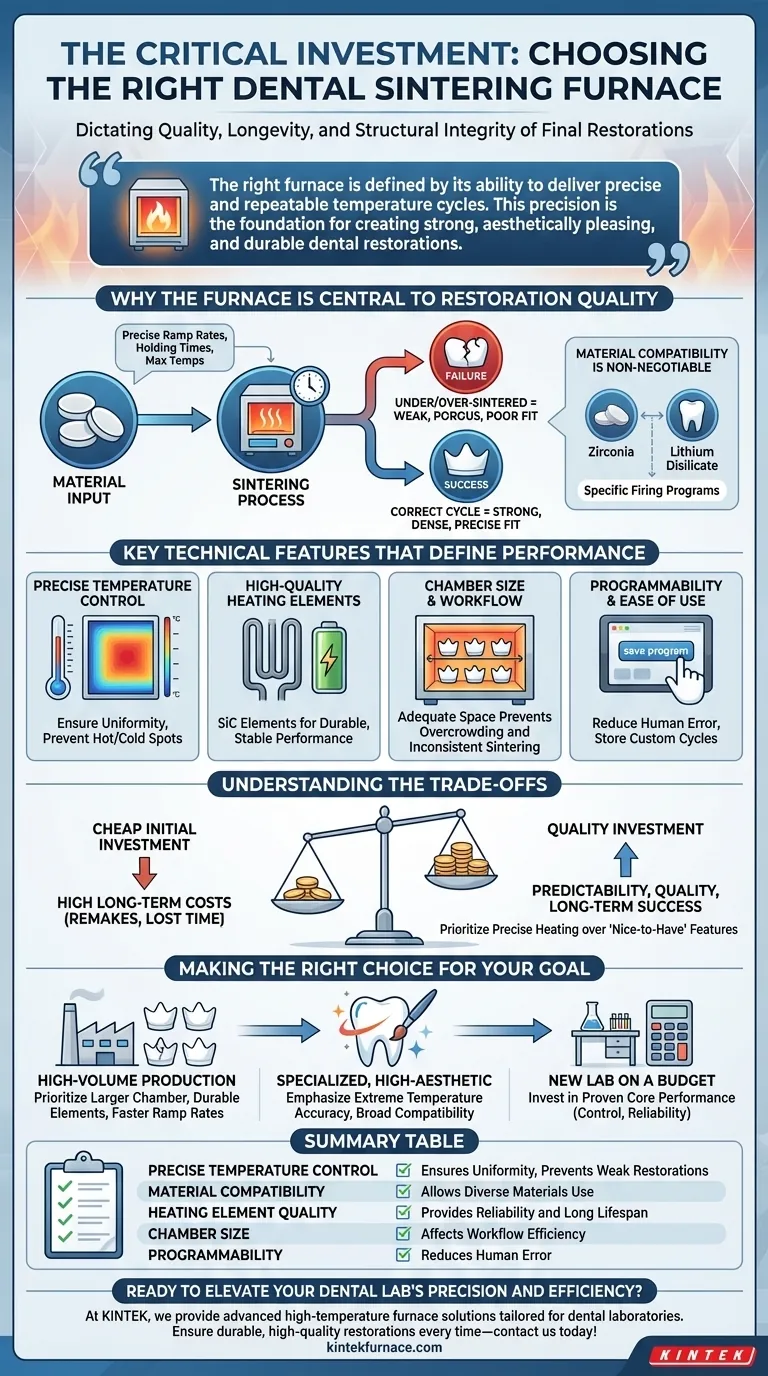

Why the Furnace Is Central to Restoration Quality

A dental furnace's primary function in restorative dentistry is sintering, a process that densifies and strengthens materials like zirconia. This process is what gives a crown or bridge its final strength and stability.

The Link Between Sintering and Structural Integrity

The sintering cycle involves precise control over heating rates (ramp rates), holding times, and maximum temperatures.

Deviations from the material manufacturer's recommended cycle can result in under-sintered or over-sintered restorations. Under-sintering leads to a weak, porous structure prone to fracture, while over-sintering can cause shrinkage and poor marginal fit.

Material Compatibility is Non-Negotiable

Different dental materials, such as zirconia and lithium disilicate, have unique and strict sintering requirements.

A furnace must be capable of executing the specific firing programs for the materials you use. Investing in a furnace without the required capabilities severely limits your lab's restorative options and potential for growth.

Key Technical Features That Define Performance

When evaluating a furnace, specific technical features are direct indicators of its ability to produce consistent, high-quality results. These are not just marketing points; they are essential for clinical success.

Precise Temperature Control

This is the most critical feature. The furnace must be able to hit and maintain exact temperatures throughout the chamber. Look for furnaces with high-quality thermocouples and advanced control logic to ensure uniformity and prevent hot or cold spots.

High-Quality Heating Elements

The heating elements generate the heat, and their quality determines the furnace's reliability and lifespan. Silicon carbide (SiC) elements are often preferred for their durability and ability to maintain stable performance over thousands of cycles, unlike less expensive alternatives that can degrade.

Chamber Size and Workflow Integration

The chamber must accommodate your typical workload with adequate space between restorations. Overcrowding a chamber can obstruct heat flow, leading to inconsistent sintering and failed units. Consider your current and future production volume.

Programmability and Ease of Use

Modern furnaces should allow for the easy creation and storage of custom firing programs. A clear interface reduces the risk of human error, ensuring the correct cycle is run every time.

Understanding the Trade-offs

Choosing a furnace involves balancing cost with performance. A cheap initial investment can often lead to higher long-term costs.

Cost vs. Remakes and Lost Time

A less expensive furnace with poor temperature stability will produce inconsistent results. The cost of remaking failed restorations—in terms of materials, labor, and reputational damage—quickly surpasses the initial savings from a budget furnace.

Advanced Features vs. Core Functionality

Features like cloud connectivity and remote monitoring can improve workflow efficiency but are secondary to the core function of precise heating. Prioritize a furnace that excels at its primary task before considering "nice-to-have" features.

Making the Right Choice for Your Goal

Your decision should align directly with your laboratory's primary objectives.

- If your primary focus is high-volume production: Prioritize a furnace with a larger chamber, durable heating elements, and potentially faster ramp rates to maximize throughput without sacrificing consistency.

- If your primary focus is specialized, high-aesthetic restorations: Emphasize extreme temperature accuracy and broad material compatibility to expertly handle diverse and complex cases.

- If your primary focus is establishing a new lab on a budget: Invest in a furnace with proven core performance—excellent temperature control and reliable elements—even if it means forgoing a larger capacity or advanced connectivity for now.

Investing in a quality sintering furnace is an investment in predictability, quality, and the long-term success of your work.

Summary Table:

| Key Factor | Importance |

|---|---|

| Precise Temperature Control | Ensures uniform sintering, preventing weak or failed restorations |

| Material Compatibility | Allows use of diverse materials like zirconia and lithium disilicate |

| Heating Element Quality | Provides reliability and long lifespan, e.g., silicon carbide elements |

| Chamber Size | Affects workflow efficiency and prevents overcrowding for consistent results |

| Programmability | Reduces human error with easy-to-use custom firing programs |

Ready to elevate your dental lab's precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique sintering requirements. Ensure durable, high-quality restorations every time—contact us today to discuss how our furnaces can transform your workflow!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab