A Bell Jar Furnace is a specialized thermal processing system designed specifically for treating highly sensitive and delicate components. Its core purpose is to achieve a superior surface finish and material purity by creating a tightly controlled vacuum or inert gas atmosphere, protecting the workpiece from any form of contamination.

The true value of a Bell Jar Furnace is not its heating capability, but its exceptional atmospheric control. It sacrifices high-volume throughput for an ultra-clean processing environment, making it indispensable for applications where even microscopic levels of oxidation or contamination would cause failure.

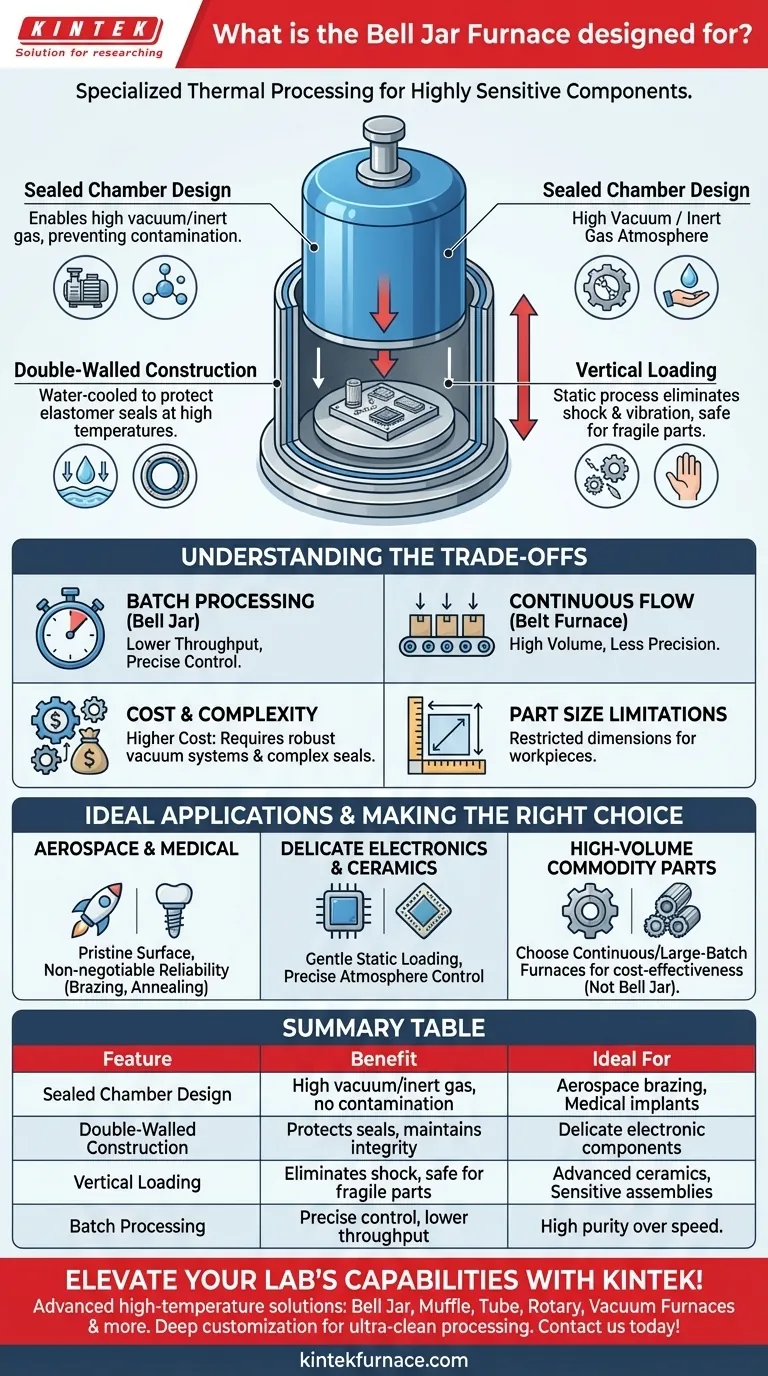

How a Bell Jar Furnace Achieves Precision

The unique design of the Bell Jar Furnace is what enables its specialized function. Unlike a standard box furnace, its architecture is built from the ground up to isolate the workpiece from the outside environment.

The Sealed Chamber Design

The furnace gets its name from its primary feature: a cylindrical chamber, or "bell," that is lowered over the parts, which rest on a stationary hearth. This creates an exceptionally tight seal.

This design is fundamental to achieving a high vacuum or maintaining the purity of a specific process gas like argon or nitrogen.

The Double-Walled Construction

Many bell jar chambers are double-walled. The space between the walls is typically filled with circulating water for cooling.

This cooling is not for the part itself but to protect the elastomer seals (O-rings) that create the vacuum-tight environment. By keeping the seals cool, the furnace can maintain its atmospheric integrity even at extremely high internal temperatures.

Vertical Loading for Delicate Components

The "bell" lifts vertically, allowing operators to carefully place components on the stationary base. Once loaded, the bell is lowered, and the process begins.

This static loading process eliminates the mechanical shock, vibration, and potential for damage that can occur in conveyor-style furnaces, making it ideal for fragile assemblies or materials with fine geometric features.

Understanding the Trade-offs

While unmatched in its precision, the Bell Jar Furnace is a specialized tool with clear operational trade-offs that make it unsuitable for many common applications.

Batch Processing vs. Continuous Flow

Bell Jar Furnaces are inherently batch-processing systems. A single batch must be loaded, sealed, processed, cooled, and unloaded before the next one can begin.

This results in significantly lower throughput compared to continuous belt furnaces used for high-volume manufacturing.

Cost and Complexity

The systems required to create and maintain a high-quality vacuum—including robust vacuum pumps, complex seals, and precise gas flow controllers—add significant cost and complexity to the furnace.

Maintenance of the seals and vacuum system is critical and more demanding than that for a simple atmospheric furnace.

Limitations on Part Size

The physical size of the bell and the hearth strictly limits the dimensions of the workpiece. While designs vary, they are generally not used for very large or irregularly shaped components that are more easily processed in larger car-bottom or box furnaces.

Making the Right Choice for Your Process

Deciding if a Bell Jar Furnace is right for you requires evaluating your process priorities.

- If your primary focus is aerospace-grade brazing or medical implant annealing: The furnace's ability to prevent oxidation and ensure a pristine surface is non-negotiable and essential for component reliability.

- If your primary focus is high-volume heat treatment of commodity steel parts: A more cost-effective continuous or large-batch atmospheric furnace is the superior choice.

- If your primary focus is processing delicate electronic components or advanced ceramics: The gentle, static loading and precise atmospheric control justify the lower throughput.

Ultimately, choosing a Bell Jar Furnace is a strategic decision to prioritize material purity and surface integrity above all other factors.

Summary Table:

| Feature | Benefit | Ideal For |

|---|---|---|

| Sealed Chamber Design | Enables high vacuum or inert gas atmosphere, preventing contamination | Aerospace brazing, medical implants |

| Double-Walled Construction | Protects seals with cooling, maintaining integrity at high temperatures | Delicate electronic components |

| Vertical Loading | Eliminates shock and vibration, safe for fragile parts | Advanced ceramics, sensitive assemblies |

| Batch Processing | Ensures precise control for each load, though lower throughput | Applications requiring high purity over speed |

Elevate your lab's capabilities with KINTEK's advanced high-temperature solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with Bell Jar Furnaces and other systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for ultra-clean processing. Ready to achieve superior material purity and surface integrity? Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments