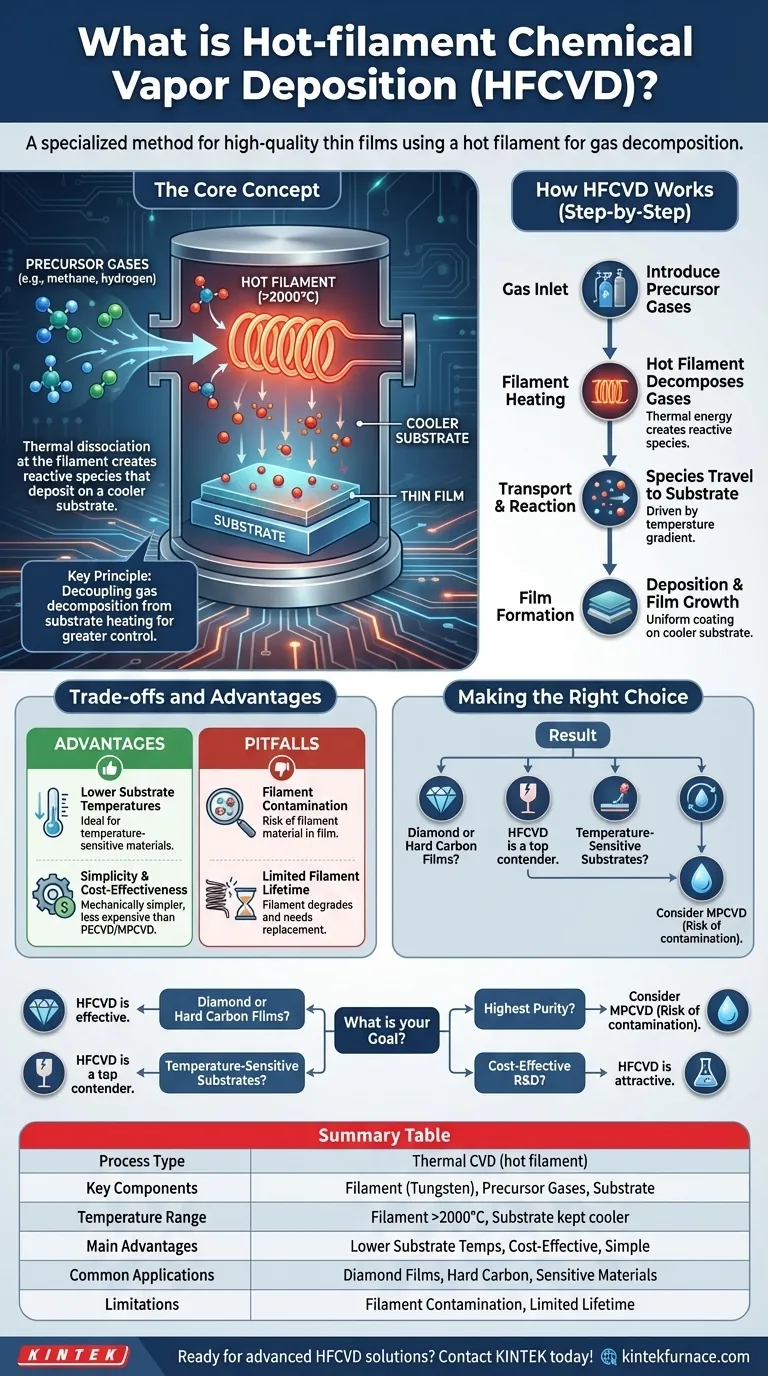

In essence, Hot-filament Chemical Vapor Deposition (HFCVD) is a specialized method for creating high-quality thin films. It works by using an extremely hot filament, typically made of a metal like tungsten, to thermally break down precursor gases. The resulting reactive chemical species then deposit onto a nearby, cooler substrate, forming a uniform and durable coating.

HFCVD separates the task of gas decomposition from substrate heating. By using a dedicated hot filament to break down precursor gases, it allows for high-quality film deposition on cooler substrates, offering greater control and efficiency than methods that rely solely on heating the entire chamber.

The Foundation: Understanding General CVD

Before diving into the specifics of HFCVD, it's crucial to understand the parent process: Chemical Vapor Deposition (CVD).

The Core Process

CVD is a widely used industrial technique for applying thin films and coatings to a surface, known as a substrate. The process involves introducing one or more precursor gases into a vacuum chamber.

The Role of Energy

For a film to form, the stable precursor gases must be broken down, or "decomposed," into more reactive chemical species. This requires a significant energy input, typically in the form of high heat or plasma.

Film Formation

Once decomposed, these reactive species adsorb onto the substrate surface, where they undergo chemical reactions to form a solid, stable thin film. The thickness of this film is controlled by factors like deposition time and gas concentration. Common applications include protective coatings that guard against corrosion and oxidation.

How HFCVD Refines the Process

HFCVD is a specific type of thermal CVD that uses a unique and elegant mechanism to supply the required energy.

The Critical Component: The Hot Filament

The defining feature of HFCVD is a metallic filament (often tungsten or tantalum) positioned a short distance above the substrate. This filament is electrically heated to very high temperatures, frequently exceeding 2000°C (3632°F).

This filament serves a dual purpose: it is the primary source of thermal energy for gas decomposition and can also act as a catalyst, accelerating the chemical reactions.

Gas Decomposition at the Filament

Precursor gases introduced into the chamber are broken down when they come into contact with the intensely hot filament. This process, known as thermal dissociation, efficiently creates the reactive species needed for film growth.

The Temperature Gradient

A key principle of HFCVD is the deliberate temperature difference between the extremely hot filament and the significantly cooler substrate. This gradient is critical for controlling the deposition process.

Gas decomposition happens at the filament, not on the substrate. This prevents the substrate from needing to be heated to excessively high temperatures, which could damage it.

Controlled Deposition on the Substrate

The reactive species generated at the filament travel across the short gap to the cooler substrate. There, they adhere to the surface and form the desired high-quality film, building up layer by layer.

Understanding the Trade-offs and Advantages

Like any technical process, HFCVD has a distinct set of strengths and weaknesses that make it suitable for specific applications.

Key Advantage: Lower Substrate Temperatures

Because the filament does the heavy lifting of gas decomposition, the substrate can be kept at a much lower temperature compared to other thermal CVD methods. This makes HFCVD ideal for coating temperature-sensitive materials.

Key Advantage: Simplicity and Cost-Effectiveness

HFCVD systems are often mechanically simpler and less expensive to build and operate than more complex plasma-assisted CVD (PECVD) or microwave plasma CVD (MPCVD) systems.

Potential Pitfall: Filament Contamination

The primary drawback of HFCVD is the risk of filament evaporation. Over time, atoms from the hot filament material can vaporize and become incorporated into the growing film as impurities, which can be detrimental for high-purity applications.

Potential Pitfall: Filament Lifetime

The extreme temperatures and reactive gas environment cause the filament to degrade and become brittle over time. This limited lifetime means filaments require periodic replacement, which can affect the long-term consistency and uptime of the process.

Making the Right Choice for Your Goal

HFCVD is a powerful tool when its characteristics align with your objective. Use these points as a guide.

- If your primary focus is depositing diamond or hard carbon films: HFCVD is a classic, well-established, and effective method for these materials.

- If your primary focus is coating temperature-sensitive substrates: The lower substrate temperature requirement is a significant advantage that makes HFCVD a top contender.

- If your primary focus is achieving the absolute highest film purity: Be cautious, as filament contamination is a known risk. A filament-free method like MPCVD may be a better choice.

- If your primary focus is cost-effective R&D or small-scale production: The relative simplicity and lower capital cost of an HFCVD system make it a very attractive option.

Ultimately, understanding the distinct role of the filament is the key to mastering the HFCVD process and leveraging its unique capabilities for your project.

Summary Table:

| Aspect | Details |

|---|---|

| Process Type | Thermal CVD using a hot filament for gas decomposition |

| Key Components | Filament (e.g., tungsten), precursor gases, substrate |

| Temperature Range | Filament >2000°C, substrate kept cooler |

| Main Advantages | Lower substrate temperatures, simplicity, cost-effectiveness |

| Common Applications | Diamond films, hard carbon coatings, temperature-sensitive materials |

| Limitations | Risk of filament contamination, limited filament lifetime |

Ready to enhance your lab's capabilities with tailored HFCVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures we precisely meet your unique experimental needs for efficient, high-quality thin film deposition. Contact us today to discuss how we can support your research and production goals!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What is the use of CVD machine? Transform Surfaces with Atomic-Level Precision

- What is a CVD machine? Build High-Performance Materials from Gas with Precision

- What are the key properties of diamond that make it a promising semiconductor material? Unlock Next-Gen Electronics

- What limitations does CVD have in coating large surfaces? Overcome Scale Challenges with Custom Solutions

- What are the advantages of CVD? Achieve Unmatched High-Purity, Conformal Thin Films