In short, a retort furnace is a specialized piece of equipment that uses a sealed vessel—the "retort"—to heat materials in a highly controlled atmosphere. This design separates the material being processed from the furnace's heating elements and the outside air, allowing for precise management of the internal environment, which is critical for advanced manufacturing and laboratory work.

The key takeaway is that by isolating the workload in a sealed retort, the furnace grants complete control over the atmosphere. This single design feature prevents unwanted chemical reactions like oxidation and enables sophisticated heat treatment processes that are impossible in a standard, open-air furnace.

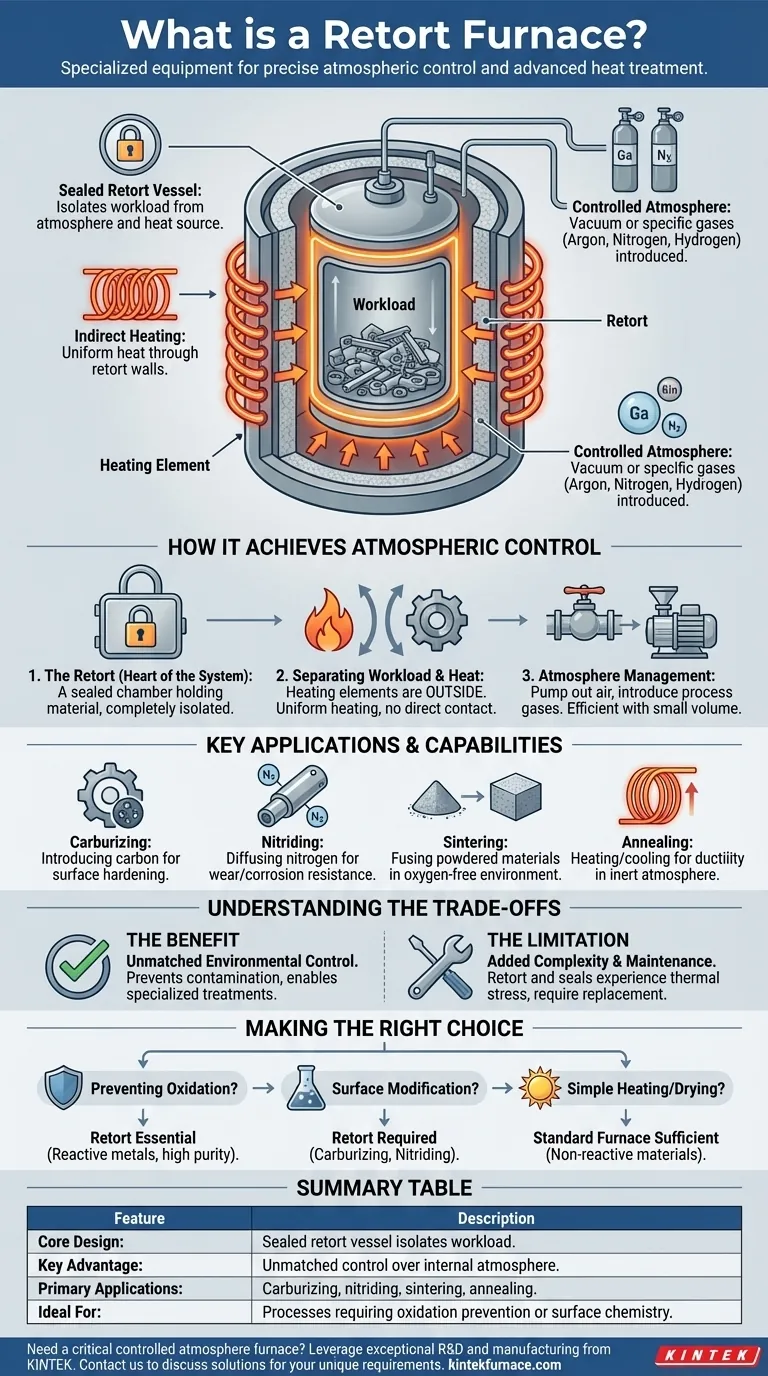

How a Retort Furnace Achieves Atmospheric Control

The defining characteristic of a retort furnace is its ability to create a specific, high-purity environment. This capability stems directly from its core design principle: separation.

The Central Role of the Retort

The "retort" is the heart of the system. It is a sealed chamber, often a cylindrical vessel made of metal or ceramic, that holds the material being processed.

This vessel is completely isolated from the furnace's internal workings and the ambient air outside.

Separating the Workload from the Heat Source

Unlike some furnaces where materials are directly exposed to flames or heating elements, a retort furnace heats the workload indirectly.

Heating elements, which can be electric or gas-powered, are located outside the retort. Heat is transferred through the retort's walls to the material inside, ensuring uniform heating without direct contact.

The Atmosphere Control System

Because the retort is a sealed, closed-loop system, its internal atmosphere can be precisely managed. Air can be pumped out to create a vacuum, and specific gases like argon, nitrogen, or hydrogen can be introduced.

This design is highly efficient, as the small, sealed volume requires very little process gas to maintain the desired atmosphere.

Key Applications and Capabilities

The precise environmental control of a retort furnace unlocks processes that rely on specific chemical interactions at high temperatures.

Advanced Heat Treatment Processes

Retort furnaces are essential for treatments that modify the surface chemistry of metals.

- Carburizing: Introducing carbon into the surface of steel to harden it.

- Nitriding: Diffusing nitrogen into a metal's surface to enhance wear and corrosion resistance.

- Sintering: Fusing powdered materials together using heat, a process often requiring an oxygen-free environment.

- Annealing: Heating and slowly cooling a material to reduce hardness and increase ductility, often done in an inert atmosphere to prevent surface scaling.

Achieving High Purity and Consistency

For reactive metals or advanced materials, any exposure to oxygen at high temperatures can cause oxidation, compromising the material's integrity.

The sealed retort guarantees a pure environment, ensuring that the only reactions occurring are the ones intended by the process. This leads to highly consistent and repeatable results.

Understanding the Trade-offs

While powerful, the retort furnace design involves specific trade-offs compared to simpler atmospheric furnaces.

The Benefit: Unmatched Environmental Control

The primary advantage is undeniable: a retort furnace offers unparalleled control over the processing atmosphere. This prevents contamination and enables specialized chemical treatments.

The Limitation: Added Complexity and Maintenance

The retort itself is a component that experiences extreme thermal stress. Over time, it can degrade and require replacement.

The seals that ensure the chamber is airtight are also critical wear parts. This adds a layer of complexity and maintenance not present in simple, open-air box furnaces.

Making the Right Choice for Your Process

Deciding whether you need a retort furnace comes down to the chemical requirements of your heating process.

- If your primary focus is preventing oxidation: A retort furnace is essential for processing reactive metals or materials where surface purity is critical.

- If your primary focus is surface modification: Processes like carburizing and nitriding fundamentally require a retort furnace to introduce and contain the necessary reactive gases.

- If your primary focus is simple heating or drying: For non-reactive materials where exposure to air is acceptable, a standard atmospheric furnace is a more straightforward and cost-effective solution.

Ultimately, a retort furnace is the definitive tool when the integrity of the atmosphere is as important as the temperature itself.

Summary Table:

| Feature | Description |

|---|---|

| Core Design | Sealed retort vessel isolates the workload from heating elements and ambient air. |

| Key Advantage | Unmatched control over internal atmosphere (vacuum, inert, or reactive gases). |

| Primary Applications | Carburizing, nitriding, sintering, and annealing of reactive or sensitive materials. |

| Ideal For | Processes where preventing oxidation or enabling specific surface chemistry is critical. |

Need a furnace for a critical controlled atmosphere process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary, and specialized Retort Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements, whether for R&D or production.

Contact us today to discuss how our retort furnace solutions can ensure the purity and consistency your process demands.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance