In essence, a porcelain furnace is a specialized, high-precision oven used in dental laboratories to fire, sinter, and glaze ceramic materials. This controlled heating process is what transforms raw dental porcelain or ceramic powders into the strong, durable, and lifelike crowns, bridges, veneers, and other restorations that are ultimately placed in a patient's mouth.

The core function of a porcelain furnace is not simply to heat, but to execute a precisely programmed thermal cycle. This transforms fragile ceramic materials into a final prosthesis with the specific strength, fit, and aesthetic properties required to mimic a natural tooth.

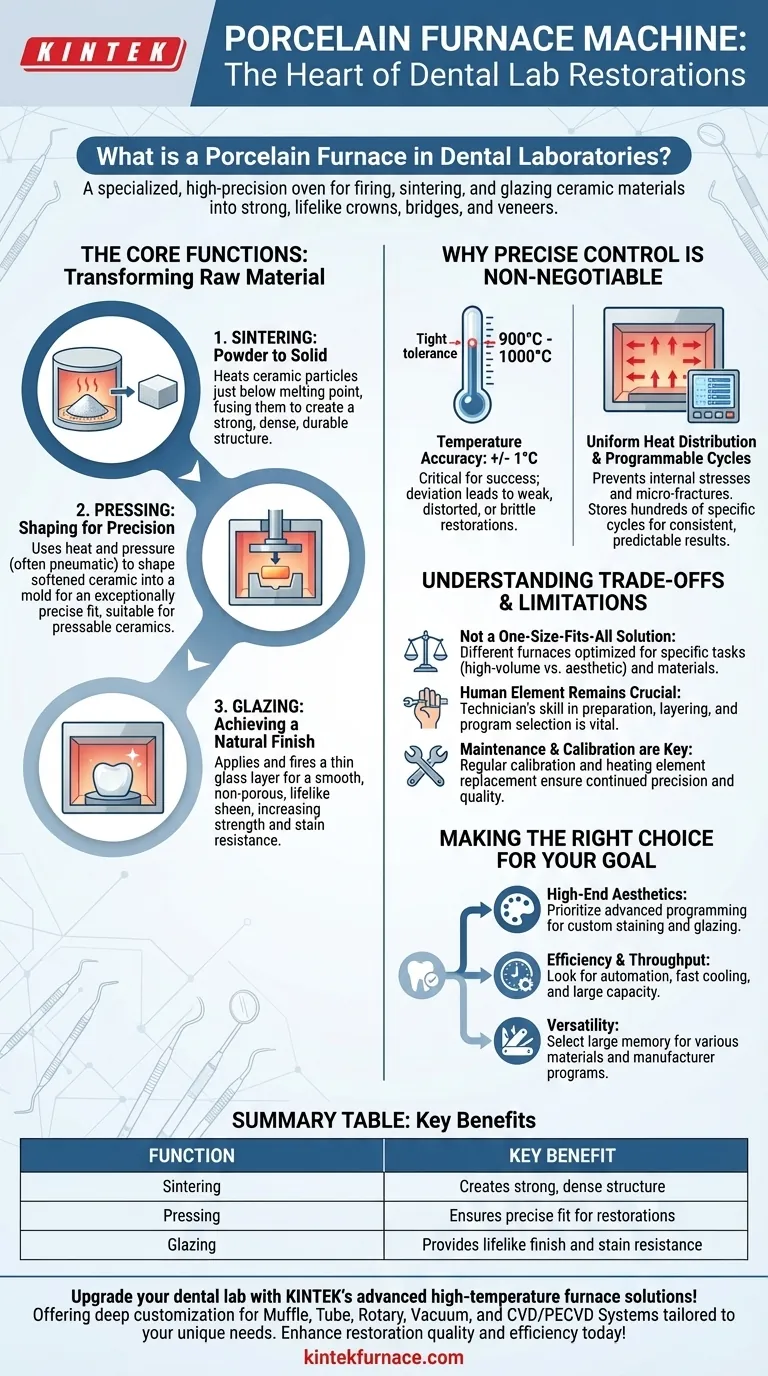

The Core Functions of a Porcelain Furnace

A porcelain furnace is a multi-purpose tool that performs several distinct, critical processes in the creation of a dental restoration. Each stage leverages precise temperature control to achieve a different outcome.

Sintering: From Powder to Solid

The foundational process is sintering. Dental porcelain starts as a mixture of fine ceramic particles. Sintering heats these particles to a temperature just below their melting point.

This causes the particles to fuse together, eliminating the spaces between them and creating a dense, hardened structure. This is what gives the final restoration its foundational strength and durability.

Pressing: Shaping for Precision

For certain types of restorations, particularly those made from materials like lithium disilicate, the furnace is used for pressing. A pre-heated ceramic ingot is made malleable (plasticized) by the heat.

The furnace then uses pressure, often pneumatic, to press this softened ceramic into a mold, creating a restoration with an exceptionally precise fit.

Glazing: Achieving a Natural Finish

The final step is often glazing. A thin layer of specialized glass is applied to the sintered restoration and fired at a specific temperature.

This glaze firing creates a smooth, non-porous, and lustrous surface. This not only provides the vital, lifelike sheen of a natural tooth but also makes the restoration stronger and more resistant to staining.

Why Precise Control is Non-Negotiable

You cannot substitute a porcelain furnace with a generic kiln. The success of a modern dental restoration is entirely dependent on the furnace's ability to manage every variable of the heating and cooling process with extreme accuracy.

The Critical Role of Temperature Accuracy

Most dental ceramics are fired at temperatures between 900°C and 1000°C. A high-quality furnace maintains this heat with an accuracy of +/- 1°C.

Any deviation can be catastrophic. Too low a temperature results in incomplete sintering and a weak restoration. Too high a temperature can cause the ceramic to melt, distort, lose its color, or become brittle.

Uniform Heat Distribution

The furnace chamber is designed to provide perfectly uniform heat. If one part of a crown heats or cools faster than another, it creates internal stresses.

These stresses can lead to micro-fractures that compromise the long-term integrity of the restoration, causing it to fail prematurely once in the patient's mouth.

Programmable Firing Cycles

Different ceramic systems require unique firing cycles. This involves not just the peak temperature but also the rate of heating, the duration the temperature is held (the "hold time"), and the rate of cooling.

Modern furnaces store hundreds of programs, allowing technicians to select the precise, manufacturer-recommended cycle for any given material, ensuring consistent and predictable results every time.

Understanding the Trade-offs and Limitations

While essential, a porcelain furnace is a tool that requires expertise. The quality of the output is a direct result of the machine's capabilities and the technician's skill.

Not a One-Size-Fits-All Solution

While many furnaces are versatile, some are optimized for specific tasks. A furnace designed for high-volume pressing may have different features than one designed for the intricate layering and staining of highly aesthetic anterior crowns. The material choice (e.g., feldspathic porcelain vs. zirconia) also dictates the type of furnace required.

The Human Element Remains Crucial

An advanced furnace can execute a program flawlessly, but it cannot compensate for poor initial preparation. The technician's skill in building up porcelain layers, applying stains, and choosing the correct program is just as critical as the machine's performance.

Maintenance and Calibration are Key

To maintain the required +/- 1°C precision, furnaces must be regularly calibrated. The heating element (muffle) is a consumable component that degrades over time and requires eventual replacement. Ignoring maintenance guarantees a decline in the quality and consistency of the restorations.

Making the Right Choice for Your Goal

The ideal furnace depends entirely on the primary goals of the dental laboratory.

- If your primary focus is high-end aesthetics: Prioritize a furnace with advanced programming flexibility for custom staining and glazing cycles, ensuring you can achieve subtle color and translucency effects.

- If your primary focus is efficiency and throughput: Look for a furnace with a reliable automation system, a fast cooling process, and a large capacity for firing multiple units at once.

- If your primary focus is versatility: Select a furnace with a large memory for storing many manufacturer programs and the ability to handle both standard porcelains and modern pressable ceramics.

Ultimately, the porcelain furnace is the instrument that bridges the gap between raw material and final restoration, empowering dental technicians to turn science into art.

Summary Table:

| Function | Description | Key Benefit |

|---|---|---|

| Sintering | Fuses ceramic particles at high heat | Creates strong, dense structure |

| Pressing | Shapes softened ceramics with pressure | Ensures precise fit for restorations |

| Glazing | Applies and fires a glass layer | Provides lifelike finish and stain resistance |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for dental laboratories. Our deep customization capabilities ensure your porcelain furnace precisely meets unique experimental needs, delivering superior performance for sintering, pressing, and glazing ceramics. Contact us today to discuss how we can enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab