In a laboratory setting, a muffle furnace is an essential high-temperature chamber oven used for processes requiring thermal treatment in a controlled and isolated environment. Its primary applications involve determining the non-combustible or "ash" content of a sample, performing heat treatments on metals and ceramics, and conducting materials research at temperatures far exceeding a standard oven's capability.

The defining feature of a muffle furnace is its internal chamber—the "muffle"—which isolates the sample from direct contact with the heating elements. This design ensures highly uniform heating and prevents contamination, making it indispensable for precise analytical work and material transformation at high temperatures.

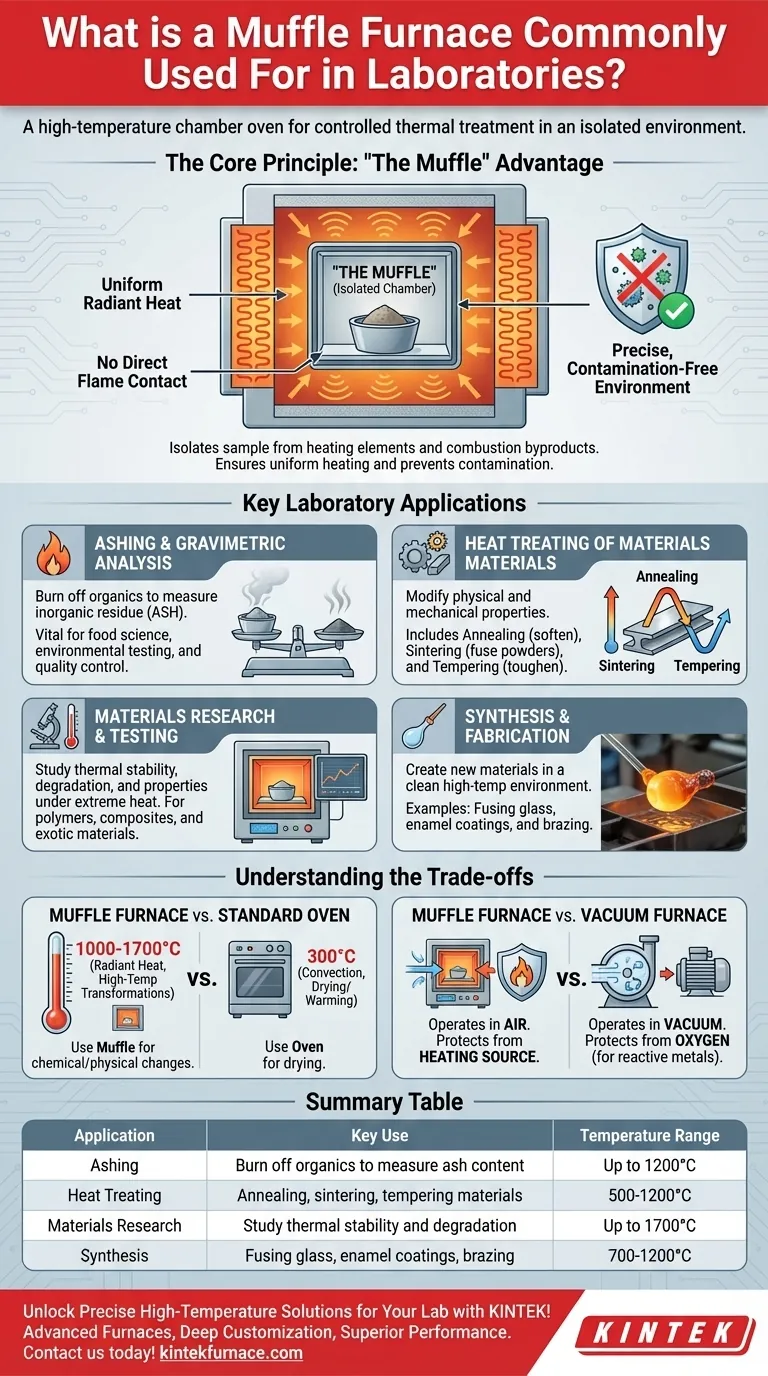

The Core Principle: Why Use a Muffle Furnace?

Understanding the purpose of a muffle furnace begins with its name. The "muffle" is a sealed chamber that separates the material being heated from the furnace's heating elements and their combustion byproducts. This fundamental design provides two critical advantages.

To Isolate the Sample from Contaminants

The heating elements, especially in fuel-fired furnaces, can release gases and particulates that would contaminate the sample.

By placing the sample inside the muffle, you ensure that the heating process itself does not alter the sample's chemical composition. This is critical for analytical procedures like ashing, where the goal is to measure the precise weight of the remaining inorganic material.

To Achieve Uniform and Precise High Temperatures

The muffle radiates heat evenly from all sides onto the sample. This creates an extremely uniform temperature environment, free from the hot and cold spots that can occur with direct heating.

This precision is vital for processes like annealing metals or sintering ceramics, where exact temperature profiles determine the final properties of the material.

Key Laboratory Applications Explained

The unique capabilities of a muffle furnace lend it to several distinct categories of laboratory work, from quantitative analysis to materials development.

Ashing and Gravimetric Analysis

This is arguably the most common laboratory use. Ashing is the process of burning off all organic and volatile components from a sample to determine the weight of the remaining inorganic residue (the ash).

This technique, also known as gravimetric analysis or ignition testing, is fundamental in food science, environmental testing, and quality control for polymers and coal.

Heat Treating of Materials

Muffle furnaces are used to modify the physical and mechanical properties of materials through controlled heating and cooling cycles.

Key processes include:

- Annealing: Heating and slowly cooling a material (like steel or glass) to reduce hardness and increase ductility.

- Sintering: Heating powdered materials below their melting point to cause the particles to fuse together, forming a solid piece. This is common in ceramics and powder metallurgy.

- Tempering: A lower-temperature process used to increase the toughness of hardened steel.

Materials Research and Testing

Researchers use muffle furnaces to study how materials behave under extreme thermal stress.

This includes testing the thermal stability of polymers and plastics, analyzing the degradation of composites, and investigating the high-temperature properties of exotic metals and ceramics for aerospace or industrial applications.

Synthesis and Fabrication

The clean, high-temperature environment is perfect for creating new materials or objects.

Common applications include fusing glass, creating enamel coatings on metal, and advanced soldering or brazing operations that require precise temperature control without introducing contaminants into the joint.

Understanding the Trade-offs

While powerful, a muffle furnace is not the right tool for every heating task. Its value lies in understanding its specific strengths and limitations compared to other lab equipment.

Muffle Furnace vs. A Standard Laboratory Oven

A standard oven circulates hot air and typically operates up to around 300°C (572°F). A muffle furnace uses radiant heat and routinely reaches 1000-1200°C (1832-2192°F), with specialized models going much higher.

Use a standard oven for simple drying or warming. Use a muffle furnace for any process that involves chemical or physical transformation at high temperatures, such as burning, melting, or altering a material's crystal structure.

Muffle Furnace vs. A Vacuum Furnace

A muffle furnace provides excellent protection from contamination from the heating source, but it operates in ambient air by default.

A vacuum furnace is used when the sample must be protected from oxygen and other atmospheric gases, which can cause oxidation at high temperatures. If you need to heat-treat a reactive metal like titanium, a vacuum furnace is necessary. If you are ashing a food sample in air, a muffle furnace is the correct tool.

Making the Right Choice for Your Goal

To select the correct process, focus on the intended outcome for your sample.

- If your primary focus is quantitative analysis: Use the muffle furnace for ashing, moisture determination, and volatile matter tests where sample integrity is paramount.

- If your primary focus is materials science: Employ the furnace for heat treatments like annealing or sintering to precisely modify a material's physical properties.

- If your primary focus is material testing: Leverage its consistent high temperatures to test the thermal stability and degradation of polymers, ceramics, or composites.

Understanding the core principle of sample isolation is the key to effectively leveraging the muffle furnace for accurate and repeatable results in your work.

Summary Table:

| Application | Key Use | Temperature Range |

|---|---|---|

| Ashing | Burn off organics to measure ash content | Up to 1200°C |

| Heat Treating | Annealing, sintering, tempering materials | 500-1200°C |

| Materials Research | Study thermal stability and degradation | Up to 1700°C |

| Synthesis | Fusing glass, enamel coatings, brazing | 700-1200°C |

Unlock precise high-temperature solutions for your lab with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures your unique experimental needs are met with superior performance and reliability. Contact us today to discuss how our high-temperature furnace solutions can enhance your research and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination