At its core, a muffle furnace is a high-temperature oven defined by a critical design feature: its heating source is physically separated from the main chamber. Unlike conventional furnaces where the material may be exposed directly to flames or heating elements, the "muffle" acts as a barrier. This design creates a highly controlled, contamination-free environment for heat treatment.

The fundamental difference is not the temperature they can reach, but the purity of the heating environment. A muffle furnace prioritizes preventing contamination and ensuring a controlled atmosphere, which is non-negotiable for sensitive scientific and manufacturing processes.

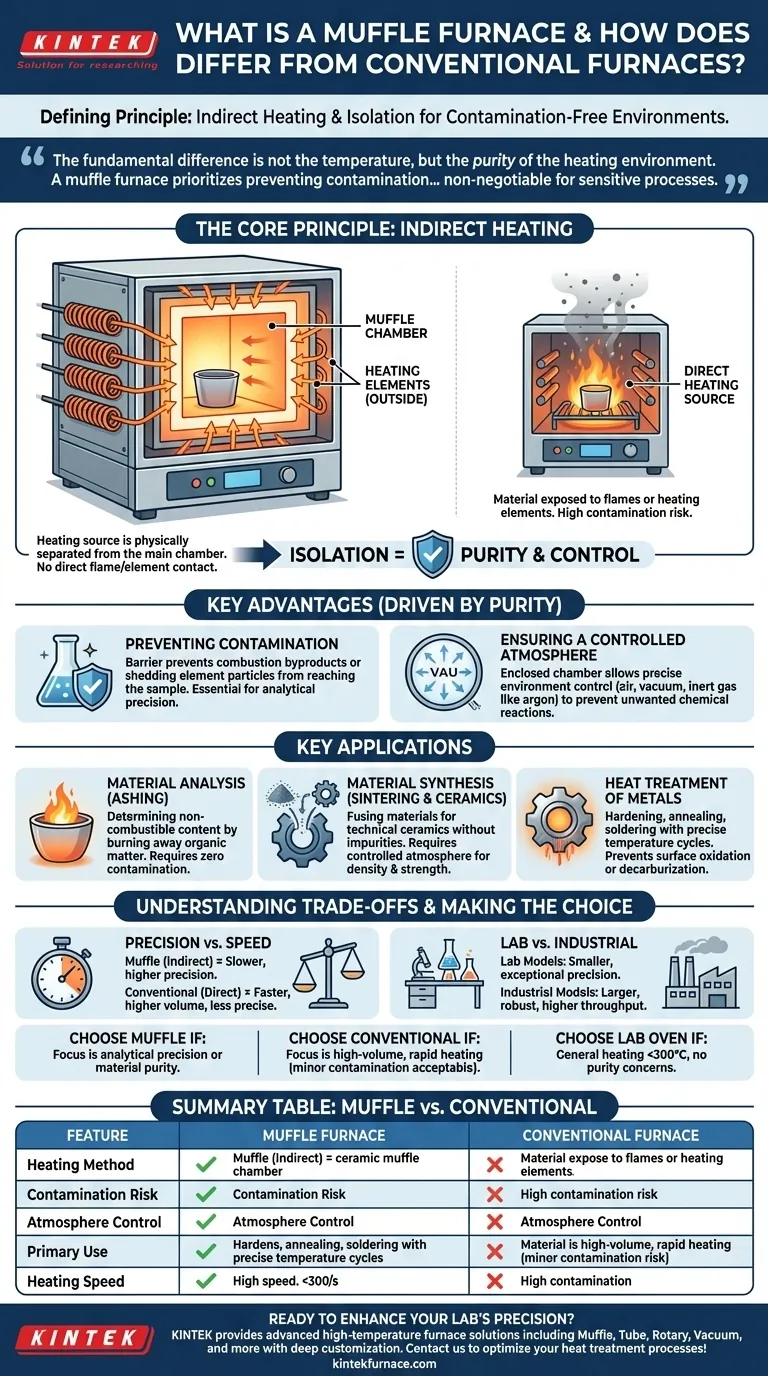

The Defining Principle: Indirect Heating and Isolation

The name "muffle furnace" comes from the muffle itself—a sealed, high-temperature chamber that contains the sample being heated. The heating process is indirect.

How a Muffle Works

The heating elements (electric coils) or flames (in a fuel-fired furnace) are on the outside of the muffle.

Heat radiates through the walls of the muffle to heat the sample inside. This ensures uniform heating without any direct contact between the heat source and the material.

Preventing Contamination

This separation is the furnace's primary advantage. It prevents contaminants from the heating source from reaching the sample.

Contaminants can include particles shed from aging electric elements or, more significantly, combustion byproducts like soot and gases from a fuel-fired source. For many applications, this level of purity is essential.

Ensuring a Controlled Atmosphere

Because the muffle is an enclosed chamber, the atmosphere inside it can be precisely controlled. This is impossible in a direct-fired furnace.

This allows for heat treatments in specific environments, such as in the air, in a vacuum, or with an inert gas like argon, which is critical for preventing unwanted chemical reactions like oxidation.

Key Applications Driven by Purity and Precision

The unique design of a muffle furnace makes it indispensable for tasks where the chemical and physical integrity of the sample must be maintained.

Material Analysis (Ashing)

Ashing is a process used to determine the inorganic, non-combustible content of a sample by burning away all organic matter.

Any contamination from the heat source would add to the final mass, leading to inaccurate results. A muffle furnace guarantees that the remaining ash is purely from the original sample.

Material Synthesis (Sintering and Ceramics)

Sintering involves heating powdered materials below their melting point to fuse them into a solid object. This is fundamental to creating technical ceramics and other advanced materials.

A pure, controlled atmosphere is required to achieve the desired density, strength, and structural properties without introducing impurities that could compromise the final product.

Heat Treatment of Metals

Processes like hardening, annealing, and soldering require precise temperature cycles.

Using a muffle furnace prevents surface reactions, such as oxidation and decarburization, that can occur when metals are heated in the presence of reactive gases, ensuring the desired metallurgical properties are achieved.

Understanding the Trade-offs

While invaluable, the muffle furnace design comes with inherent trade-offs compared to other heating methods.

Precision vs. Heating Speed

Indirect heating is generally slower than direct heating. The muffle itself acts as a thermal barrier, meaning it takes longer for the chamber to reach the target temperature.

Conventional, direct-fired furnaces can often heat materials much more rapidly, making them more efficient for high-volume processes where speed is more important than purity.

Laboratory vs. Industrial Scale

Muffle furnaces are produced for different scales. Laboratory models are typically smaller and designed for exceptional temperature precision and control for research and testing.

Industrial models are built for robustness and higher throughput in manufacturing environments, such as in glass or metal production, but still operate on the same principle of indirect heating.

Making the Right Choice for Your Application

Selecting the correct heating equipment depends entirely on the requirements of your process.

- If your primary focus is analytical precision or material purity: A muffle furnace is the definitive choice, as its isolated chamber is designed specifically to prevent contamination.

- If your primary focus is high-volume, rapid heating: A conventional direct-fired furnace may be more efficient, provided minor atmospheric contamination is acceptable for your process.

- If your primary focus is general heating below 300°C without purity concerns: A standard laboratory oven is a more practical and cost-effective solution.

Understanding this core principle of isolation empowers you to select the precise tool your process demands.

Summary Table:

| Feature | Muffle Furnace | Conventional Furnace |

|---|---|---|

| Heating Method | Indirect (separate muffle) | Direct (exposed to heat source) |

| Contamination Risk | Low (isolated chamber) | High (direct contact) |

| Atmosphere Control | High (sealed environment) | Limited or none |

| Primary Use | Sensitive applications (e.g., ashing, sintering) | General heating where purity is less critical |

| Heating Speed | Slower due to indirect heating | Faster due to direct heating |

Ready to enhance your lab's precision with contamination-free heating? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can optimize your heat treatment processes and ensure superior results for your specific applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis