In essence, a controlled atmosphere furnace is a specialized heating device that gives you precise control over not just the temperature, but also the gaseous environment surrounding the material being processed. Unlike a conventional furnace that heats objects in ambient air, this system uses a tightly sealed chamber that can be filled with specific protective or reactive gases. This control is essential for high-performance applications where exposure to oxygen or other elements in the air would compromise the material's final properties.

The fundamental problem with heating materials in a standard furnace is that air itself is chemically reactive. A controlled atmosphere furnace solves this by replacing the air with a carefully managed gas mixture, preventing unwanted reactions like oxidation and enabling specific, desired surface modifications.

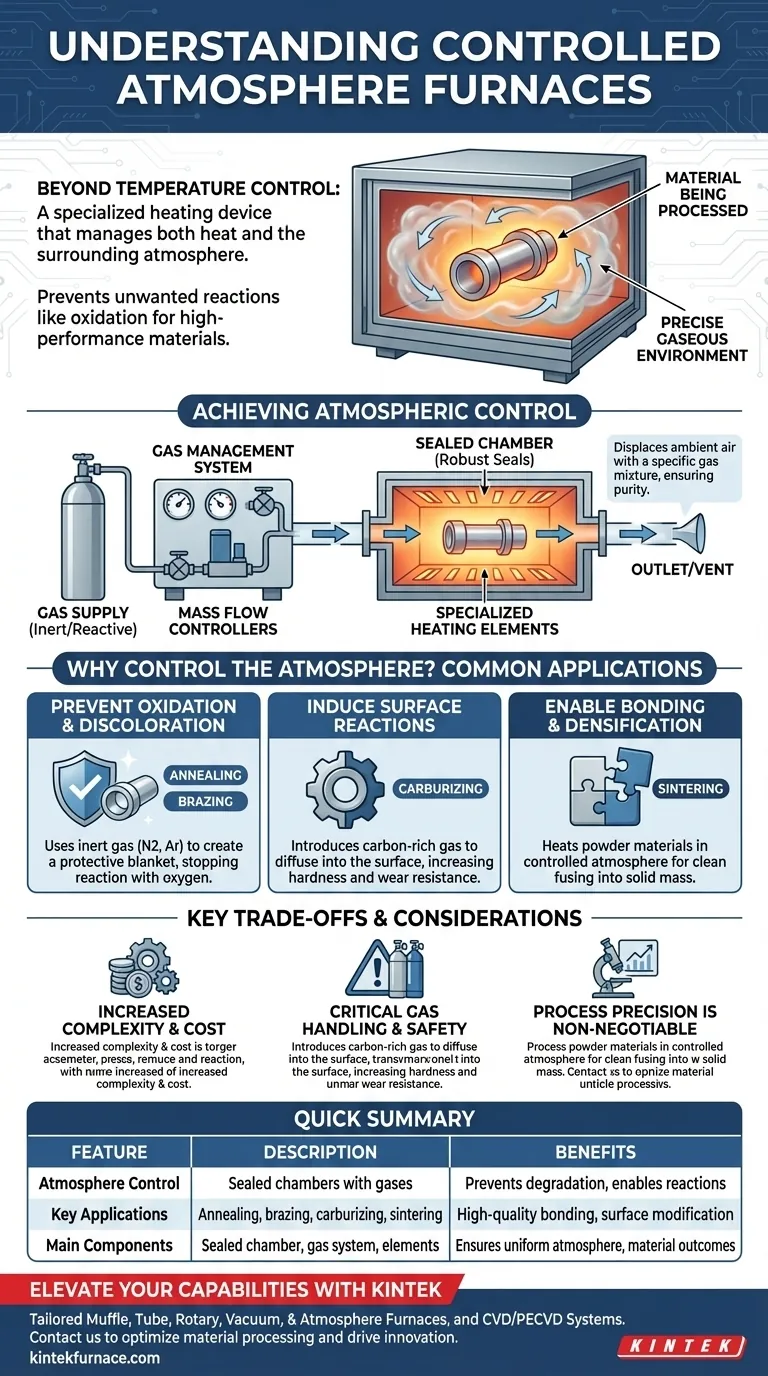

How a Controlled Atmosphere Furnace Achieves Control

A standard furnace is simply a hot box. A controlled atmosphere furnace is a complete environmental system designed around a heating chamber. Its effectiveness comes from several integrated components working together.

The Principle of Atmospheric Purity

The core function is to displace the ambient air within the chamber and replace it with a gas or gas mixture of a known composition. This is achieved in one of two ways: either by purging the chamber with a high flow of the desired gas or by first using a vacuum pump to evacuate the air before backfilling with the process gas.

Key Component: The Sealed Chamber

The entire process depends on the integrity of the heating chamber. These furnaces feature robust seals and gaskets on all doors and ports to prevent outside air from leaking in. Even a small leak can introduce oxygen and contaminate the process, defeating the furnace's purpose.

Key Component: The Gas Management System

This system is the heart of atmospheric control. It includes inlets for one or more process gases and an outlet or vent. Sophisticated systems use mass flow controllers to precisely regulate the volume and mixture of gases entering the chamber, ensuring a consistent and uniform atmosphere around the parts.

Key Component: Specialized Heating Elements

Heating elements must be chosen carefully to withstand both high temperatures and the chemical environment. Certain process gases can degrade or react with standard heating elements, leading to premature failure and contamination of the furnace atmosphere.

Why Control the Atmosphere? Common Applications

Controlling the atmosphere isn't an academic exercise; it's a requirement for achieving specific material outcomes that are impossible in open air. The chosen gas can be either protective (inert) or reactive.

To Prevent Oxidation and Discoloration

For processes like annealing or brazing, the goal is to heat a metal without it oxidizing, which would weaken it or prevent a clean bond. An inert gas like nitrogen or argon is used to create a protective "blanket," keeping oxygen away from the hot metal surface.

To Induce a Specific Chemical Reaction

In other cases, the goal is to intentionally change the material's surface chemistry. During carburizing, a carbon-rich gas is introduced to the furnace. At high temperatures, carbon atoms diffuse into the surface of steel parts, creating a hard, wear-resistant outer layer.

To Enable Material Bonding and Densification

Sintering is a process that turns metal or ceramic powders into a solid mass by heating them below their melting point. The presence of oxygen would create oxide layers on the powder particles, preventing them from bonding effectively. A controlled atmosphere ensures the particles are clean and can fuse together properly.

Understanding the Trade-offs and Considerations

While powerful, these furnaces introduce complexity and require careful operation. Understanding the trade-offs is key to using them successfully.

Increased Complexity and Cost

The sealed chamber, gas delivery plumbing, and safety systems make these furnaces significantly more complex and expensive than their standard air-atmosphere counterparts. Maintenance of seals and gas control systems is also more demanding.

Critical Gas Handling and Safety

Working with gases introduces inherent risks. Inert gases like nitrogen can pose an asphyxiation hazard in poorly ventilated areas. Reactive gases like hydrogen or ammonia can be flammable or toxic. Therefore, these furnaces must be equipped with advanced safety interlocks, leak detectors, and emergency ventilation.

Process Precision is Non-Negotiable

The success of a process depends on maintaining the precise atmospheric composition and temperature profile. This requires careful process development, accurate monitoring, and consistent gas quality. Any deviation can lead to scrapped parts.

When a Vacuum Furnace Is a Better Fit

A controlled atmosphere furnace is ideal for processes that require a specific gas environment at or near atmospheric pressure. If your process requires the removal of all gases to an extremely low pressure (a deep vacuum), then a dedicated vacuum furnace is the appropriate tool.

Making the Right Choice for Your Process

Selecting the right thermal processing equipment depends entirely on the desired outcome for your material.

- If your primary focus is preventing oxidation or discoloration: Your key need is a furnace that can maintain a positive pressure of a pure, inert gas like argon or nitrogen.

- If your primary focus is modifying a material's surface chemistry: You need a system specifically designed to safely handle reactive gases and provide uniform flow for consistent results.

- If your primary focus is simply heating a material with no atmospheric sensitivity: A standard, less complex air furnace is the more practical and cost-effective solution.

By understanding the fundamental interplay between heat and atmosphere, you can select the precise tool needed to achieve your desired material outcomes.

Summary Table:

| Feature | Description |

|---|---|

| Atmosphere Control | Uses sealed chambers with inert or reactive gases to prevent oxidation or induce specific reactions. |

| Key Applications | Annealing, brazing, carburizing, and sintering for metals and ceramics. |

| Main Components | Sealed chamber, gas management system, specialized heating elements. |

| Benefits | Prevents material degradation, enables surface modifications, and ensures high-quality bonding. |

Elevate your laboratory's capabilities with KINTEK's advanced controlled atmosphere furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures your unique experimental needs are met precisely. Contact us today to discuss how our high-temperature furnace solutions can optimize your material processing and drive innovation in your research or production.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What does nitrogen do in a furnace? Create an Inert, Oxygen-Free Atmosphere for Superior Results