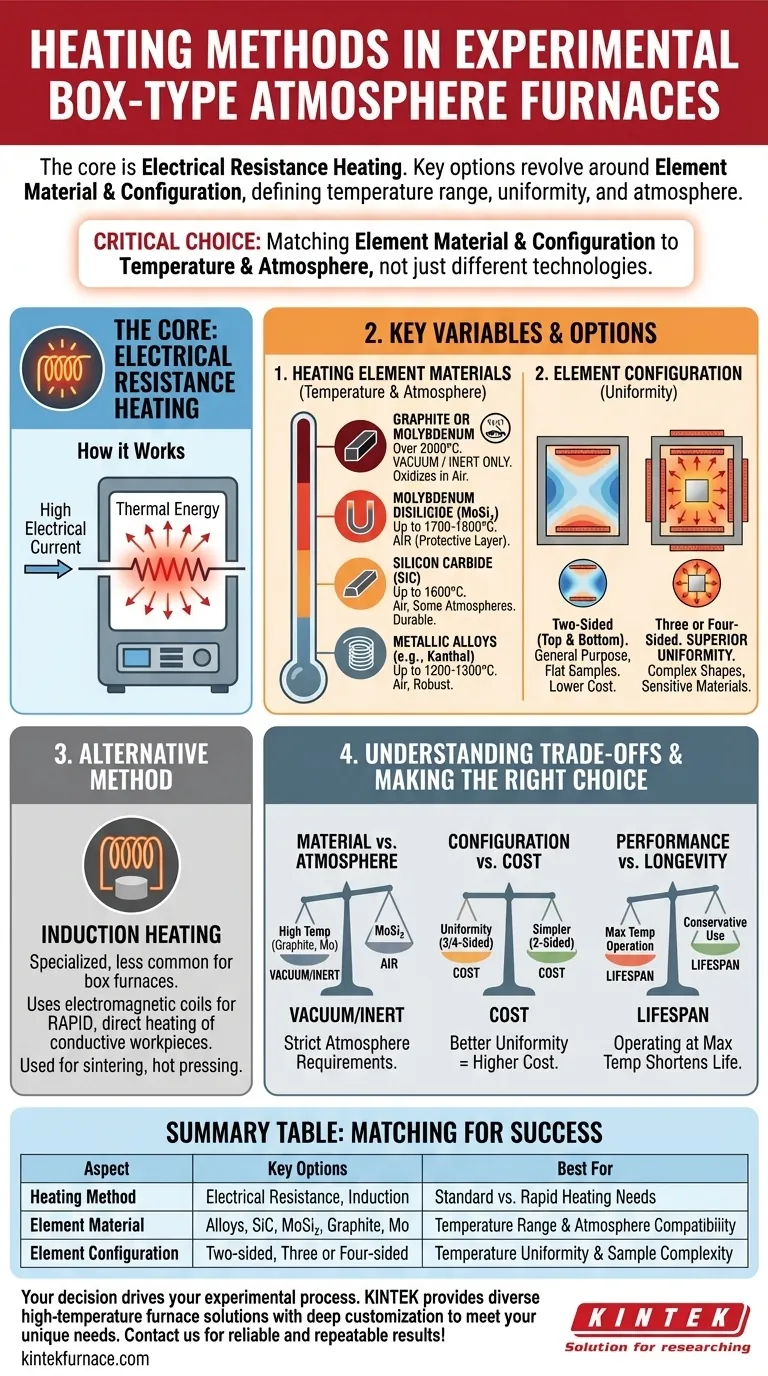

At their core, experimental box-type atmosphere furnaces primarily rely on electrical resistance heating. The key options are not just about the heating method itself, but about the material used for the heating elements and their physical placement within the furnace, which together dictate temperature range, uniformity, and atmospheric compatibility.

The most critical choice you will make is not between fundamentally different heating technologies, but in matching the heating element's material (e.g., graphite, molybdenum, SiC) and its configuration (e.g., two-sided vs. three-sided) to your specific temperature requirements and processing atmosphere.

The Core Heating Method: Electrical Resistance

Nearly all standard box-type atmosphere furnaces operate using the principle of electrical resistance. This method is reliable, controllable, and well-understood.

How Resistance Heating Works

The concept is straightforward: a high electrical current is passed through a specially designed material with high electrical resistance. This resistance causes the material, known as the heating element, to become extremely hot, and it then radiates this thermal energy into the furnace chamber to heat your sample.

Common Heating Element Materials

The material of the heating element is the single most important factor determining the furnace's maximum temperature and atmospheric compatibility.

- Metallic Alloys (e.g., Kanthal): These iron-chromium-aluminum alloys are common for lower-temperature applications, typically up to 1200-1300°C. They are robust and work well in air.

- Silicon Carbide (SiC): SiC elements are used for mid-to-high temperature work, often up to 1600°C. They are durable and can operate in air and some controlled atmospheres.

- Molybdenum Disilicide (MoSi₂): These are the standard for very high-temperature applications in air, capable of reaching 1700-1800°C. They form a protective silica layer that prevents oxidation.

- Graphite or Molybdenum: These elements are used for very high temperatures (often over 2000°C) but must be used in a vacuum or an inert/reducing atmosphere. They will rapidly oxidize and fail if operated in air at high temperatures.

Understanding Heating Element Configurations

Where the heating elements are placed inside the furnace has a direct impact on temperature uniformity throughout the chamber.

Two-Sided (Top and Bottom) Heating

In this configuration, elements are placed only at the top and bottom of the processing chamber. This is a simpler and more cost-effective design, suitable for general-purpose applications or processing flat samples where vertical heat distribution is sufficient.

Three or Four-Sided Heating

Here, elements are placed on the sides in addition to the top and bottom. This creates a more homogenous heating environment, enveloping the sample in heat from multiple directions.

Why Configuration Matters for Uniformity

A three or four-sided heating configuration significantly reduces thermal gradients and "cold spots" within the furnace. This superior temperature uniformity is critical for processes involving complex shapes, sensitive materials, or any experiment where every part of the sample must be at the exact same temperature.

Alternative Method: Induction Heating

While less common for general-purpose box furnaces, induction heating is a distinct method used in more specialized systems.

How Induction Heating Works

Induction heating uses electromagnetic coils to generate a powerful, high-frequency magnetic field. When a conductive material (like a metal sample) is placed inside this field, it induces electrical currents within the material itself, causing it to heat up rapidly from the inside out.

When to Consider Induction

This method, often called "medium frequency heating," is not a standard option for a typical box furnace. It is used in specialized furnaces for applications like metal sintering or hot pressing, where direct, rapid heating of the conductive workpiece is the primary goal.

Understanding the Trade-offs

Selecting the right heating system involves balancing performance, cost, and operational constraints.

Element Material vs. Atmosphere

This is the most critical trade-off. High-temperature elements like graphite and pure molybdenum offer incredible performance but impose a strict requirement for a vacuum or inert gas atmosphere. Using them in air will lead to immediate failure. Conversely, elements like MoSi₂ are designed specifically for high-temperature use in air.

Configuration vs. Cost

A furnace with three or four-sided heating will provide superior temperature uniformity but will be more expensive than a two-sided model. The additional elements, power connections, and control systems add to the overall cost.

Performance vs. Longevity

Operating any heating element consistently at its absolute maximum rated temperature will shorten its lifespan. For better longevity and reliability, it is wise to select a furnace with a maximum temperature rating that is comfortably above your typical operating temperature.

Making the Right Choice for Your Goal

Your decision should be driven entirely by the demands of your experimental process.

- If your primary focus is maximum temperature uniformity: Opt for a furnace with three or four-sided heating to minimize thermal gradients across your sample.

- If your primary focus is high-temperature operation (above 1600°C) in an air atmosphere: Prioritize furnaces with Molybdenum disilicide (MoSi₂) heating elements.

- If you are working under a vacuum or inert atmosphere at very high temperatures: Ensure your chosen heating element material, such as graphite or molybdenum, is specified for that environment.

- If your primary focus is general-purpose annealing below 1200°C: A simpler two-sided configuration with metallic alloy elements is often a reliable and cost-effective solution.

Ultimately, matching the heating element material and its configuration to your specific material and thermal process is the key to achieving reliable and repeatable experimental results.

Summary Table:

| Aspect | Key Options | Best For |

|---|---|---|

| Heating Method | Electrical Resistance, Induction | Standard vs. rapid heating needs |

| Element Material | Metallic Alloys, SiC, MoSi₂, Graphite, Molybdenum | Temperature range and atmosphere compatibility |

| Element Configuration | Two-sided, Three or Four-sided | Temperature uniformity and sample complexity |

Struggling to select the perfect heating setup for your experiments? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements—ensuring optimal performance, longevity, and cost-efficiency. Let us help you achieve reliable and repeatable results—contact us today to discuss your needs!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity