When a PTC ceramic heating element reaches its preset temperature, its internal electrical resistance rises dramatically. This increase in resistance automatically chokes off the flow of current, which in turn drastically reduces the heat it generates. It is a self-regulating mechanism inherent to the material itself.

The critical takeaway is that these heaters don't rely on external thermostats to prevent overheating. Their safety and temperature stability are built directly into the physics of the ceramic material, which is designed to automatically reduce its power output as it reaches a specific temperature.

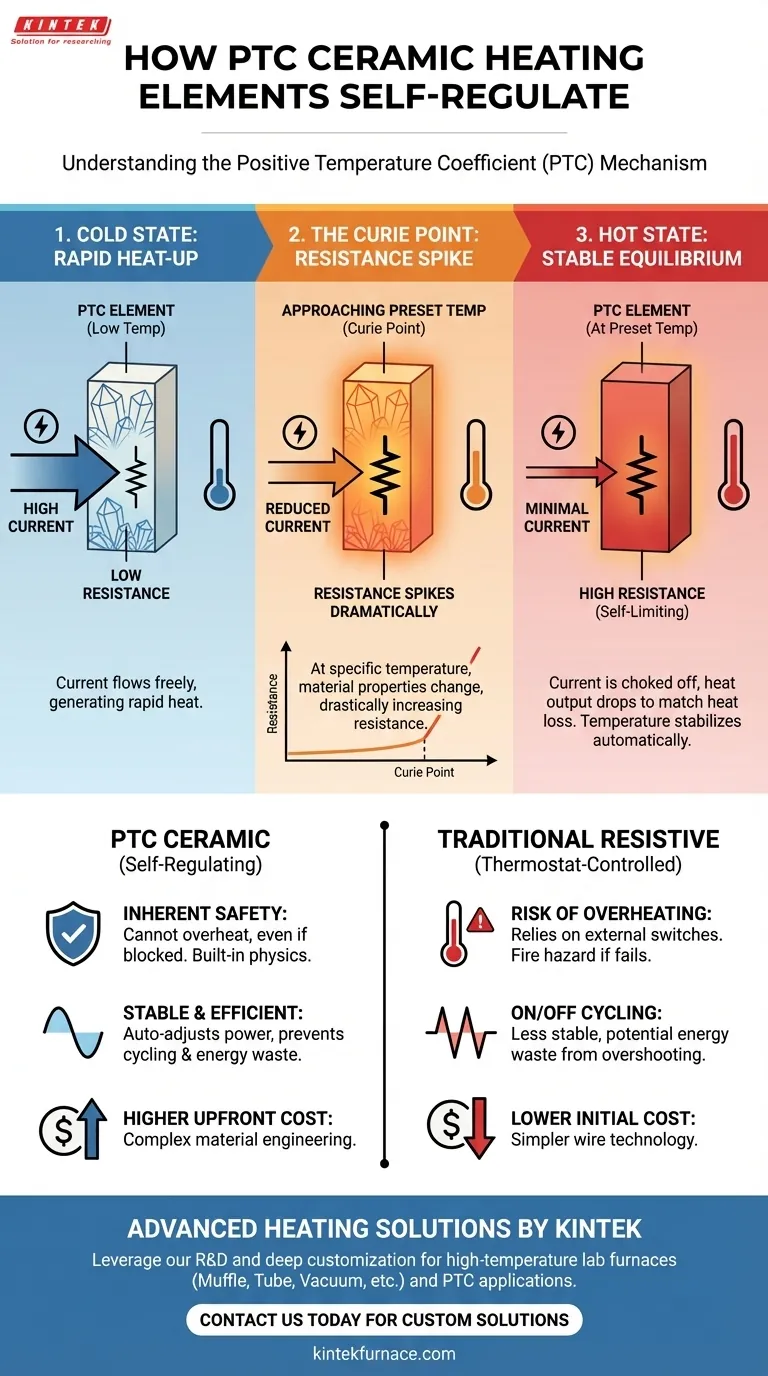

The Principle of Self-Regulation: PTC Ceramics

The behavior you're asking about is the defining characteristic of a specific class of heaters known as Positive Temperature Coefficient (PTC) ceramic heaters. Their function is elegantly simple and incredibly reliable.

What is "Positive Temperature Coefficient"?

The term Positive Temperature Coefficient means the material's electrical resistance increases as its temperature increases. This is the opposite of most common conductors.

This property is engineered into specialized ceramic materials, often based on Barium Titanate.

The "Curie Point": The Built-in Switch

The resistance in a PTC ceramic doesn't just increase smoothly. It rises exponentially at a very specific, predetermined temperature known as the Curie Point or "switch temperature."

This Curie Point is the "preset temperature" of the element. It’s not set by a dial, but is a fixed physical property of that specific ceramic's chemical composition.

How This Stops Heat Production

Think of the PTC element as a smart, self-closing valve.

When the element is cold, its resistance is very low. This allows a large amount of electrical current to flow through it, causing it to heat up very quickly.

As the element approaches its Curie Point, its resistance spikes. This high resistance acts as a barrier, severely limiting the current. Since the heat generated is directly related to the current flowing through it, the heat output plummets.

The element then naturally hovers at this equilibrium temperature, drawing just enough power to compensate for the heat it loses to the surrounding air.

PTC vs. Traditional Heaters

This self-regulating behavior is a fundamental advantage over older heating technologies.

Traditional Resistive Heaters

Most conventional electric heaters use a simple resistance wire (like Nichrome) that has a relatively stable resistance regardless of its temperature.

To control temperature, these heaters rely entirely on an external thermostat and thermal cutoff switches. The system works in a crude on/off cycle: heat to a set point, turn off, cool down, turn back on.

The PTC Advantage: Inherent Safety

The most significant benefit of PTC technology is safety. If airflow is blocked (e.g., a fan fails or a vent is covered), a traditional heater will continue to generate maximum heat, quickly becoming a fire hazard.

In the same failure scenario, a PTC heater's temperature will rise slightly, its resistance will spike, and it will automatically cut its own power. This self-limiting function makes it virtually impossible for the element itself to overheat.

The PTC Advantage: Efficiency and Stability

PTC heaters are also more efficient in practice. They deliver a powerful surge of heat when cold for a rapid warm-up, but then automatically reduce their power consumption as the target temperature is reached.

This avoids the constant on/off cycling of a thermostatically-controlled heater, leading to a more stable room temperature and preventing wasted energy from overshooting the set point.

Understanding the Trade-offs

While powerful, PTC technology is not the solution for every application. It's important to understand its limitations.

Material Complexity and Cost

Engineering a ceramic to have a precise Curie Point is a more advanced manufacturing process than simply drawing a resistance wire. This can make PTC heating elements more costly upfront than their traditional counterparts.

Fixed Operational Temperature

The self-regulating temperature is a fixed property of the material. A space heater using a PTC element may offer high and low settings, but this is typically achieved by changing fan speed or using multiple elements—not by changing the element's core temperature.

This makes PTC heaters less suitable for applications requiring a wide, user-adjustable temperature range, such as a laboratory oven.

Making the Right Choice for Your Goal

Understanding this core mechanism allows you to choose the right technology based on your primary objective.

- If your primary focus is safety and reliability: PTC ceramic technology is the superior choice because its self-regulating nature prevents overheating at a fundamental material level.

- If your primary focus is responsive heating and stable temperatures: The ability of a PTC element to provide a high initial power output that then automatically tapers off delivers both rapid heating and excellent stability.

- If your primary focus is the lowest possible component cost for a simple device: A traditional resistive wire with a separate thermostat might be cheaper, but you must account for the added complexity and potential failure points of the external control system.

By design, a PTC ceramic element intrinsically protects itself from overheating, a feature that transforms how we approach safe and efficient heating.

Summary Table:

| Feature | PTC Ceramic Heating Element | Traditional Resistive Heater |

|---|---|---|

| Temperature Regulation | Self-regulating via material resistance | Requires external thermostat |

| Safety | Inherently safe, prevents overheating | Prone to overheating risks |

| Efficiency | High initial power, auto-reduces for stability | On/off cycling, potential energy waste |

| Cost | Higher upfront due to material complexity | Lower initial cost |

| Temperature Range | Fixed Curie Point, limited adjustability | Wide, user-adjustable range |

Ready to enhance your lab's safety and efficiency with advanced heating solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our PTC ceramic technologies can benefit your specific applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C