To maximize the thermal efficiency of a split tube furnace, the most critical features are the inclusion of insulating vestibules at the ends of the heating chamber and the use of graded, multi-layered insulation. These elements work together to minimize heat loss, which is the fundamental challenge in any high-temperature system.

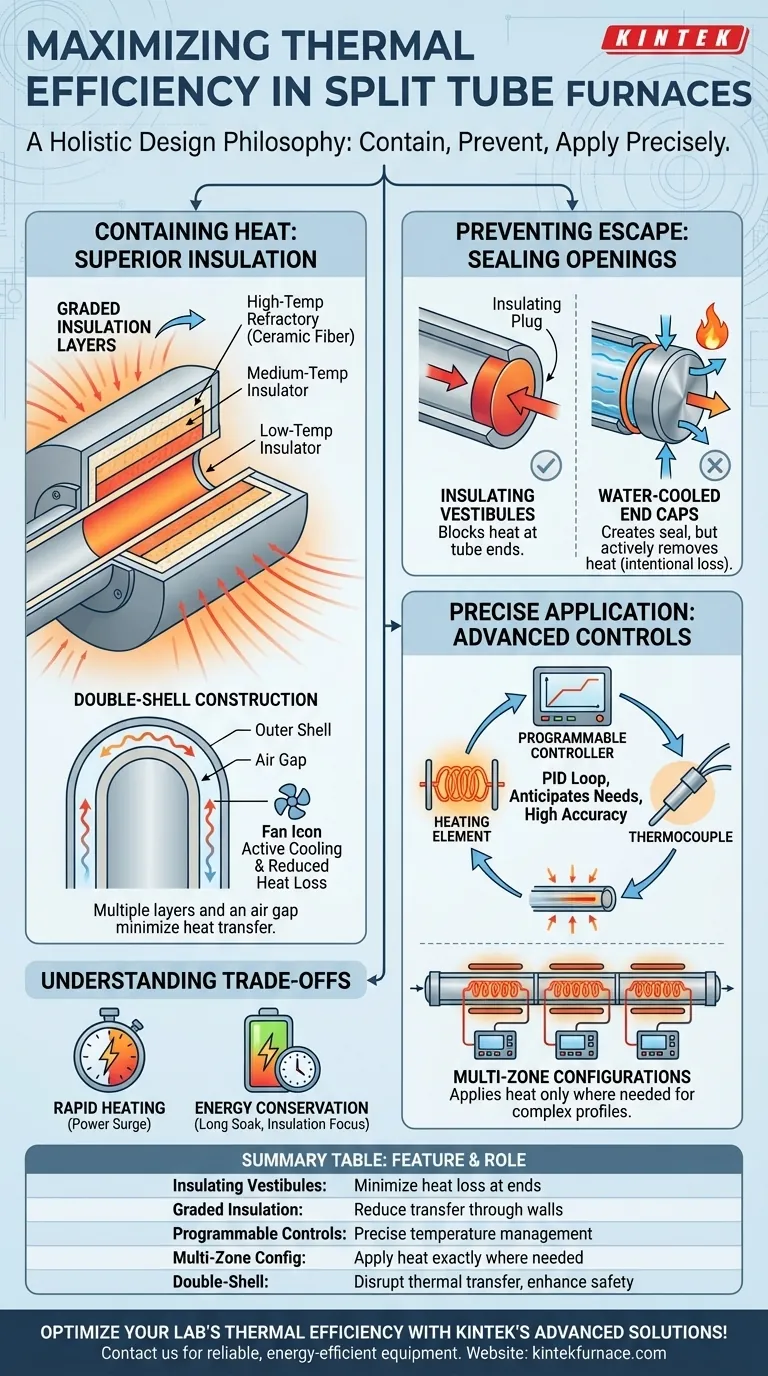

True thermal efficiency is not achieved by a single component, but by a holistic design philosophy focused on three core principles: containing heat with superior insulation, preventing its escape at openings, and applying it precisely with advanced controls.

The Foundation of Efficiency: Containing Heat

The primary goal of thermal efficiency is to keep the generated heat concentrated on the sample and prevent it from escaping into the surrounding environment. This is accomplished primarily through the furnace body's insulation.

Graded Insulation Layers

A single layer of insulation is good, but graded layers are superior. This design uses multiple, different types of insulation materials arranged in layers, similar to dressing for cold weather.

Each layer is optimized for a specific temperature range. The innermost layer is a high-temperature refractory material like ceramic fiber, while outer layers are lower-temperature, less expensive insulators. This approach minimizes heat transfer through the furnace walls far more effectively than a single, thick layer of one material.

Double-Shell Construction

Related to graded insulation is the concept of double-shell construction. This design creates an air gap between the inner and outer furnace casings.

This gap disrupts thermal transfer and, when combined with fans, helps keep the outer surface cool to the touch. This not only improves safety but is a direct indicator of reduced heat loss and higher efficiency.

Precision Control: Preventing Wasted Energy

Generating heat is only half the battle; applying it without waste is equally important. Inefficient control systems waste energy by overshooting temperature setpoints and failing to adapt to changing conditions.

Programmable Controls and Feedback Loops

Modern furnaces use fully programmable controllers that do more than just turn the heat on and off. They use sophisticated algorithms (like PID loops) to anticipate heating needs, ramp temperature smoothly, and hold a setpoint with high accuracy.

This precision is made possible by a thermocouple, which acts as a feedback sensor. It constantly measures the actual temperature, allowing the controller to make micro-adjustments and prevent the thermal drift common in simple resistance wire elements. This ensures the furnace only consumes the exact energy needed.

Multi-Zone Configurations

For processes requiring a specific temperature gradient, a multi-zone furnace is more efficient than a single-zone model.

Instead of heating a long tube to one uniform temperature, a multi-zone furnace uses independent heating elements and controllers for different sections. This allows you to apply heat only where it's needed, drastically reducing the total energy consumed for complex thermal profiles.

Understanding the Trade-offs and Common Misconceptions

Choosing the right features requires understanding that some are designed for process needs, not necessarily for thermal efficiency. Confusing them can lead to a suboptimal configuration.

Insulating Vestibules vs. Water-Cooled End Caps

This is a critical distinction. Insulating vestibules are plugs made of insulating material placed at the ends of the process tube. Their sole purpose is to block heat from escaping, directly increasing thermal efficiency.

Water-cooled end caps, however, are designed to create a vacuum-tight seal for atmosphere control. They actively remove heat from the ends of the furnace to protect rubber O-rings and instrumentation. While essential for vacuum or controlled gas applications, they create a point of intentional heat loss and work against maximum thermal efficiency.

Rapid Heating vs. Energy Conservation

Many furnaces boast rapid heating rates, which saves valuable production time. However, reaching a high temperature as quickly as possible often requires a significant surge in power.

For processes with long "soak" times where the furnace holds a temperature for hours, the initial ramp time is a small fraction of the total energy use. In these cases, the quality of the insulation and control stability are far more important for overall energy efficiency than the heating rate.

Making the Right Choice for Your Goal

The most "efficient" furnace is the one best suited to your specific application. Use your primary goal to guide your feature selection.

- If your primary focus is Maximum Thermal Efficiency: Prioritize furnaces with thick, graded insulation and ensure you use insulating end vestibules.

- If your primary focus is Process Repeatability: Invest in a multi-zone furnace with a high-quality programmable controller and thermocouple feedback.

- If your primary focus is a Controlled Atmosphere or Vacuum: You will need specialized end caps (likely water-cooled), but add insulating vestibules inboard of the seals to reclaim some of the lost thermal efficiency.

Ultimately, understanding how these features function as a system empowers you to select a furnace that performs efficiently for your specific scientific or production goals.

Summary Table:

| Feature | Role in Thermal Efficiency |

|---|---|

| Insulating Vestibules | Minimize heat loss at tube ends |

| Graded Insulation Layers | Reduce heat transfer through walls |

| Programmable Controls | Ensure precise temperature management |

| Multi-Zone Configurations | Apply heat only where needed |

| Double-Shell Construction | Disrupt thermal transfer for safety and efficiency |

Optimize your lab's thermal efficiency with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, supported by deep customization capabilities to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your processes with reliable, energy-efficient equipment!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis