To achieve a balanced temperature field, a rotary tube sintering furnace relies on a combination of core design principles and specific engineering features. The most critical contributors are the mechanical rotation of the tube for material mixing, the use of multiple, independently controlled heating zones to compensate for heat loss, high-quality insulation to maintain thermal stability, and an advanced control system that integrates these elements.

Achieving thermal balance in a rotary tube furnace is not about a single component, but a system of interacting features. It combines the continuous mechanical mixing from rotation with precise, multi-zoned thermal management and robust insulation to create a stable and uniform processing environment.

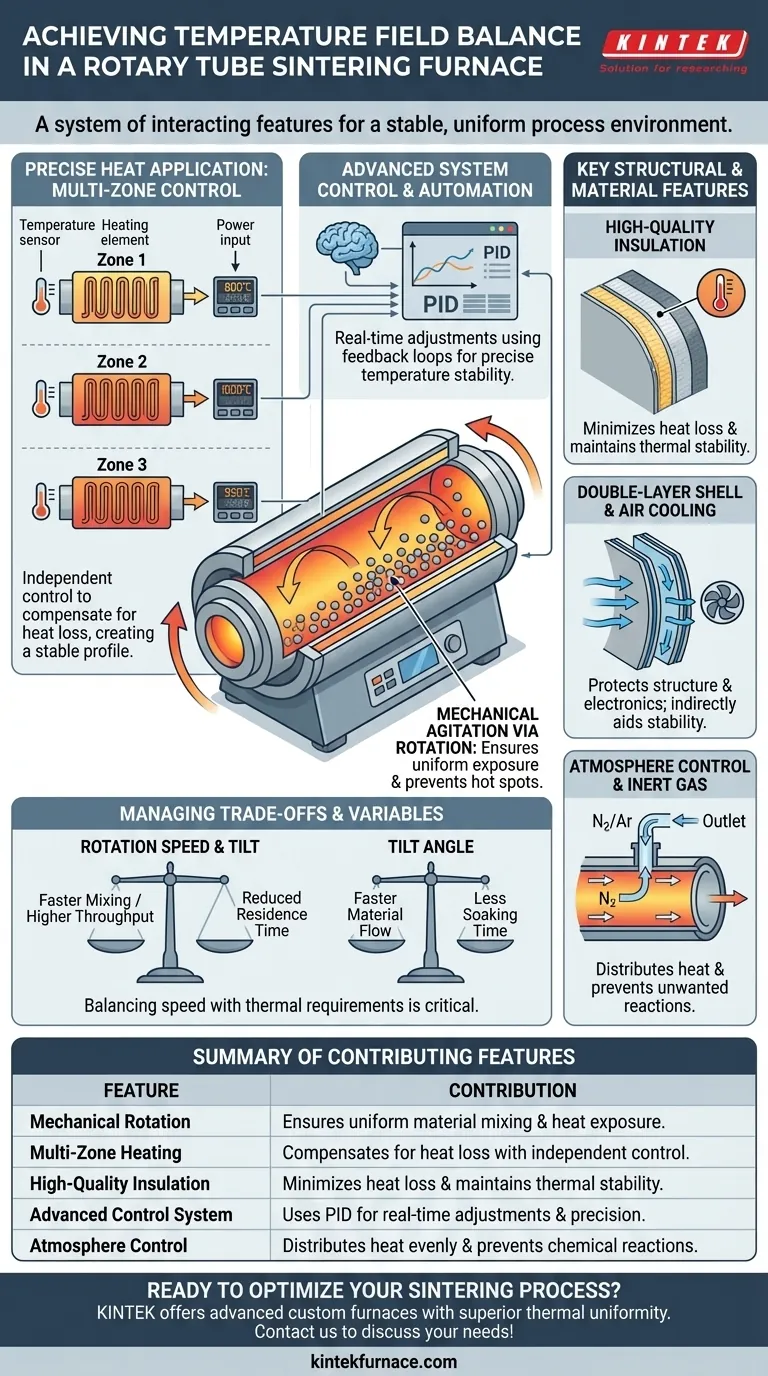

The Core Principles of Thermal Uniformity

True temperature balance, or uniformity, is the primary goal of a sintering furnace. In a rotary tube furnace, this is achieved by addressing heat application, retention, and control through several coordinated mechanisms.

Mechanical Agitation via Rotation

The defining feature of the furnace is its rotation. As the tube turns, the material inside is continuously tumbled and mixed.

This constant agitation ensures that all particles are uniformly exposed to the heat source, preventing hot spots and ensuring the entire batch reaches the target temperature consistently. Without rotation, material at the bottom and center would heat much slower than material near the walls.

Precise Heat Application through Multi-Zone Control

A long furnace tube naturally loses more heat at the ends than in the middle. To counteract this, high-performance furnaces are divided into multiple heating zones.

Each zone has its own temperature sensor and independent heating element control. This allows the control system to supply more energy to the end zones to compensate for heat loss, creating a flat and stable temperature profile along the entire length of the tube where the material resides.

Advanced System Control and Automation

The "brain" of the furnace is its process control system. This system uses feedback loops, often from PID (Proportional-Integral-Derivative) controllers, to interpret data from temperature sensors.

It then makes real-time adjustments to the power supplied to each heating zone. This high degree of automation ensures the temperature remains stable and precisely follows the desired profile, even as material moves through the furnace.

Key Structural and Material Features

The physical construction of the furnace is designed to support the core principles of thermal control and stability.

High-Quality Insulation and Refractory Linings

The furnace tube is housed within a shell lined with high-quality insulation and refractory materials.

This structure serves a critical purpose: minimizing heat loss to the external environment. By effectively containing the thermal energy, the insulation ensures the heating elements can work efficiently and maintains a highly stable internal temperature, reducing energy consumption and preventing external fluctuations from affecting the process.

Double-Layer Shell and Air Cooling

Many designs feature a double-layer shell with an integrated air-cooling system. This may seem counterintuitive, but its purpose is to protect the furnace's external structure and electronics.

By keeping the outer shell at a safe temperature, it ensures the longevity of the equipment and the safety of operators. This indirectly contributes to thermal balance by creating a stable, contained system where internal heat is managed predictably.

Atmosphere Control and Inert Gas

The ability to maintain a specific process atmosphere (e.g., with an inert gas like nitrogen or argon) also plays a role in thermal balance.

A consistent gas flow can help distribute heat more evenly throughout the tube. More importantly, it prevents unwanted exothermic or endothermic chemical reactions that could otherwise introduce thermal instability and disrupt the carefully controlled temperature field.

Understanding the Trade-offs and Process Variables

While these features are designed for uniformity, achieving it in practice involves managing several competing factors.

Rotation Speed vs. Residence Time

A higher rotation speed improves mixing and heat uniformity within the material bed. However, it can also cause the material to travel through the furnace faster, reducing its overall residence time at the target temperature. The optimal speed is a balance between sufficient mixing and adequate processing time.

Tilt Angle and Material Flow

The tilt angle of the furnace tube dictates the speed at which material moves from the inlet to the outlet. A steeper angle increases throughput but, like rotation speed, reduces residence time. Fine-tuning this angle is critical for balancing processing speed with thermal soaking requirements.

The Challenge of End-to-End Uniformity

Even with multi-zone control, the very ends of the tube—where cold material enters and hot material exits—are points of thermal disruption. Sophisticated furnace designs and carefully managed feed rates are necessary to minimize the impact of these transition zones on the overall process stability.

How to Prioritize Features for Your Goal

When evaluating a rotary tube furnace, your specific application should guide which features you prioritize.

- If your primary focus is maximum thermal precision: Prioritize a system with a high number of independent heating zones and an advanced PID control system with remote monitoring.

- If your primary focus is high throughput for continuous processing: Look for a robust, variable-speed rotation mechanism, adjustable tilt control, and a well-designed automated feeding system.

- If your primary focus is processing sensitive or reactive materials: Ensure the furnace has excellent atmosphere control, including precise gas handling and sealing, to prevent contamination and thermal upsets.

Ultimately, a well-balanced temperature field is the result of a holistic system design where each component works in concert to achieve a stable, repeatable process.

Summary Table:

| Feature | Contribution to Temperature Balance |

|---|---|

| Mechanical Rotation | Ensures uniform material mixing and exposure to heat, preventing hot spots |

| Multi-Zone Heating | Compensates for heat loss with independent control for stable temperature profiles |

| High-Quality Insulation | Minimizes heat loss, maintains thermal stability, and reduces energy consumption |

| Advanced Control System | Uses PID controllers for real-time adjustments to maintain precise temperature |

| Atmosphere Control | Distributes heat evenly and prevents thermal instability from chemical reactions |

Ready to enhance your lab's sintering processes with a custom high-temperature furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Rotary, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering superior thermal uniformity and efficiency. Contact us today to discuss how we can optimize your thermal processing!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing